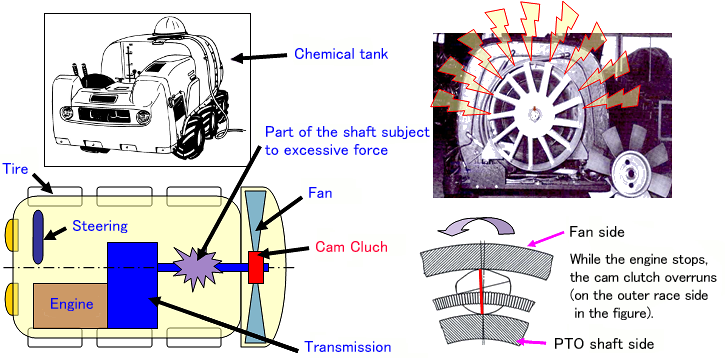

Application Examples Cam Clutch - 5. Agricultural Machinery (Fertilizer and Pesticide Sprayers)

application

Overrunning

When outer race of the Cam Clutch are engaged and torque is transmitted, the difference in rotation speed and direction of outer race causes

This is a method of use in which the wheel spins freely and repeatedly, similar to the freewheeling motion of a car.

Compatible models

- ・ 200 series

- ・ ML series, etc.

Machines used

Agricultural machinery (fertilizer and pesticide applicators)

Application Examples

Layout

Purpose of use and operation explanation

This is a riding machine used to spray pesticides and fertilizers in orchards and other areas.

A large fan and a tank for pesticides and fertilizers are attached to the rear.

When spraying pesticides or fertilizers, the fan rotates at high speed under fruit trees, etc.

At this time, the wind created by the fan turns the pesticides and fertilizers into mist and spreads it around.

This fan has a large inertia and cannot stop immediately when the engine is stopped.

For this reason, the engine will stop when work is completed, but the fan will continue to rotate, which may damage the shaft.

There is a possibility.

When the cam clutch is installed between the PTO shaft and the fan, the cam clutch receives rotation from the transmission.

This is communicated to the fan through meshing.

Also, when the engine is stopped, the cam clutch rotates freely and disconnects the PTO shaft from the fan.

Protection becomes possible.

With Tsubaki Cam Clutch...

A cam clutch is attached to a device that keeps rotating due to inertia.

The machine body, the space for the fan, the transmission torque required for the cam clutch,

The cam clutch will be selected based on factors such as rotation speed.

In the ML series (photo left), both inner race and outer race

A key groove is provided for attachment to the shaft and outer race side.

This makes it easy to install the necessary parts.

Advantages of using a Cam Clutch

- - The cam clutch automatically transitions from engagement to idling.

- - No extra switches or control devices are required, such as switching between meshing and idling, allowing for a compact design.