technical data Power-Lock Precautions

EF Series

1. Mounting on a grooved shaft

When installing Power-Lock on a shaft that already has a keyway, such as a motor shaft, the transmission torque Mt and thrust load Pax will be reduced by 10%.

- Transmission torque: Mt × 0.9

- Thrust load: Pax × 0.9

2. Installation accuracy

When mounting to Power-Lock 's straight hole boss, the boss mounting accuracy should be as shown below.

(When hub length is the same as the contact surface width between the boss and outer ring)

- Ex: Runout of hub end face 0.002 × r mm or less

- Er: Deviation of outer hub diameter 0.05mm or less

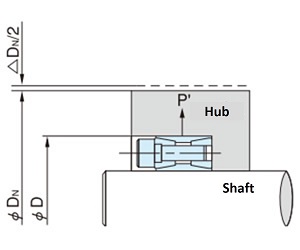

3. Deformation of outer hub diameter

When Power-Lock is attached to a boss, a surface pressure P' acts on hub diameter, causing elastic deformation on the outer diameter of the boss.

This amount of deformation cannot be determined accurately due to variations in the surface pressure P', the shape of the boss, etc., but as a rough guide it can be calculated using the following formula.

△DN ≒ DN E × 2 × K3 × P' ( DN D ) 2 - 1

- P': boss side pressure MPa

- E: Young's modulus For steel, E = 205800 MPa

- D: hub diameter mm

- D N: Outer hub diameter mm

- △D N: Deformation outer hub diameter diameter mm

- K3: hub geometry factor

(Please refer to Major Specifications page for each product.)

4. Ambient temperature

To maximize the performance of Power-Lock, use it in an ambient temperature range of -30°C to 200°C.

5. Allowable tightening torque MA

The tightening torque MA of the tightening bolts has a tolerance of ±5%.

This value is sufficient to guarantee the transmission torque Mt and thrust load Pax, and any possible errors in proper use of the torque wrench are fully absorbed.

6. Boss movement amount

EF series axial movement

Please note that when fastening the shaft and boss with an EF Power-Lock, the boss will move.

This amount of movement is affected by the amount of elastic deformation of the shaft and boss, and varies depending on the boss inner/outer diameter ratio aN, and is approximately as shown in the table below.

- aN = DN D

- D: hub diameter mm

- D N: Outer hub diameter mm

| Model number d XD Shaft diameter x outer diameter mm |

Boss movement (mm) | ||

|---|---|---|---|

| a N = 1.5 in the case of |

a N = 2.0 in the case of |

a N = 3.0 in the case of |

|

| PL010X013EF | 0.29 | 0.22 | 0.18 |

| PL011X014EF | 0.29 | 0.22 | 0.18 |

| PL012X015EF | 0.29 | 0.22 | 0.18 |

| PL014X018EF | 0.29 | 0.22 | 0.18 |

| PL015X019EF | 0.29 | 0.22 | 0.18 |

| PL016X020EF | 0.44 | 0.32 | 0.27 |

| PL017X021EF | 0.44 | 0.32 | 0.27 |

| PL018X022EF | 0.48 | 0.35 | 0.30 |

| PL019X024EF | 0.48 | 0.36 | 0.30 |

| PL020X025EF | 0.48 | 0.36 | 0.30 |

| PL022X026EF | 0.48 | 0.35 | 0.30 |

| PL024X028EF | 0.48 | 0.36 | 0.30 |

| PL025X030EF | 0.48 | 0.36 | 0.30 |

| PL028X032EF | 0.72 | 0.53 | 0.45 |

| PL030X035EF | 0.72 | 0.53 | 0.45 |

| PL032X036EF | 0.62 | 0.46 | 0.39 |

| PL035X040EF | 0.63 | 0.46 | 0.39 |

| PL038X044EF | 0.88 | 0.65 | 0.55 |

| PL040X045EF | 0.72 | 0.54 | 0.45 |

| PL042X048EF | 0.96 | 0.71 | 0.60 |

| PL045X052EF | 1.10 | 0.81 | 0.69 |

| PL048X055EF | 1.09 | 0.81 | 0.68 |

| PL050X057EF | 1.10 | 0.81 | 0.68 |

| PL055X062EF | 1.09 | 0.81 | 0.68 |

| PL060X068EF | 0.98 | 0.73 | 0.61 |

| PL065X073EF | 1.31 | 0.97 | 0.82 |

| PL070X079EF | 1.25 | 0.92 | 0.78 |

| PL075X084EF | 1.55 | 1.15 | 0.97 |

| PL080X091EF | 1.41 | 1.04 | 0.88 |

| PL085X096EF | 1.80 | 1.33 | 1.12 |

| PL090X101EF | 1.80 | 1.33 | 1.13 |

| PL095X106EF | 1.80 | 1.33 | 1.12 |

| PL100X114EF | 1.64 | 1.22 | 1.03 |

| PL110X124EF | 1.65 | 1.22 | 1.03 |

| PL120X134EF | 1.98 | 1.47 | 1.24 |

7. The need to apply oil and grease during assembly

When assembling Power-Lock, it is very important to oil the body and tightening bolts.

It is often thought that applying oil to Power-Lock will cause it to slip or the tightening bolts to loosen, but the bolt tightening torque is calculated based on efficiency when the bolt is lubricated, and oil is also essential for smooth movement on the tapered surface.

Conversely, if oil is not applied, the axial force will decrease, reducing the transmission torque by approximately 25%, and it may also cause problems such as galling of the tightening bolts, so never degrease the bearing.

For stainless steel and electroless nickel plated models, the tightening bolts are coated with a special lubricant, and the main body is designed to be used in a dry state, so do not apply oil or grease when assembling.

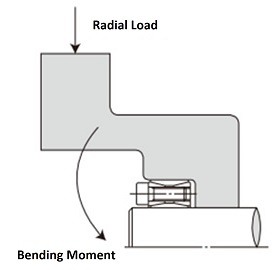

8. Bending Moment

As a general rule, Power-Lock cannot withstand bending moments. If a bending moment is applied as shown in the diagram below, please contact us.

9. Outdoor use

Even if exposed to water droplets or rainwater, the high surface pressure on the mounting contact surface of Power-Lock prevents water from entering, so performance is not reduced.

However, rust will occur on all surfaces except the contact surface. Bolts in particular are subject to large tension, so rust will reduce their strength and fastening force, causing them to break.

To prevent this, cover Power-Lock and fill it with grease to prevent rust.

If a cover cannot be attached, use the stainless steel or electroless nickel-plated specifications.