technical data Top chain Selection

If you would like to see the selection procedures and important points, please proceed below.

If you would like to narrow down or tentatively select a product series,

Please click here.

If your usage conditions have been decided and you would like a detailed selection,

Please click here.

Selection of Snap cover chain

1-1. Determining the chain size

1-1-1. Check the allowable load

Please check that the load per link is within the allowable load in Table 1.

1-1-2. Calculating the tension acting on the chain

- F = Maximum tension acting on the chain kN{kgf}

- m1 = mass of transported material (kg/m)

- m2 = Approximate chain mass (kg / m)

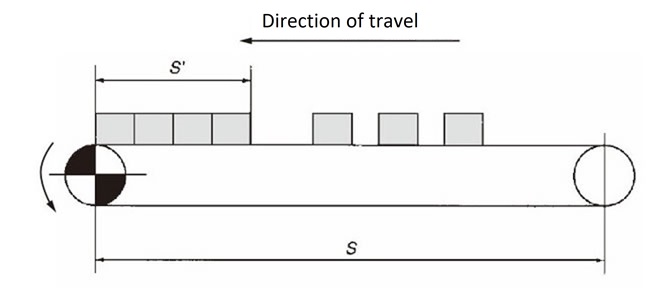

- S = Transfer distance (sprocket center distance) (m)

- S' = Length of the object that has slipped and accumulated (m)

- μ1 = coefficient of friction between chain and rail [conveying side] (see Table 2)

- μ2 = coefficient of friction between chain and rail [return-way] (see Table 3)

- μ3 = Coefficient of friction between the conveyed object and the chain (see Table 4)

- P = required power (kW)

- V = Chain speed (m/min)

- K = velocity factor (see Table 5)

- ηNote) = Mechanical transmission efficiency of the drive unit

- G = gravitational acceleration 9.80665m/s 2

Note: Please check the drive unit used to determine transmission mechanical efficiency.

Table 2. Coefficient of rolling friction between chain and rail (μ1)

| No lubrication | With lubrication |

|---|---|

| 0.21 | 0.14 |

Table 4. Dynamic friction coefficient (μ3) between conveyed object and chain (plastic cover)

| Material of the transported item | Resin Cover Material |

|---|---|

| Standard Series Conductive specifications |

|

| Steel cans aluminum cans |

0.25 |

| Paper pack | 0.3 |

| glass bottle | 0.22 |

| plastic containers | 0.25 |

| Industrial products (metal) | 0.25 |

Note: Without lubrication

Table 1. Snap cover chain load capacity

| Specification | Allowable load kN{kgf}/1 link | |||||

|---|---|---|---|---|---|---|

| RF06B-SC | RS40-SC | RS50-SC | RS60-SC | RS80-SC | RS100-SC | |

| Standard Series NP Series Lambda Specification |

0.03 {3} |

0.05 {5} |

0.07 {7} |

0.10 {10} |

0.15 {15} |

0.25 {25} |

| SS Series | 0.03 {3} |

0.05 {5} |

0.06 {6} |

0.09 {9} |

0.15 {15} |

0.25 {25} |

Table 3. Friction coefficient (μ2) between chain (plastic cover) and rail

| Resin Cover Material | Rail Material | |

|---|---|---|

| Stainless steel | Ultra high molecular weight polyethylene |

|

| Standard Series Conductive specifications |

0.25 | 0.25 |

Note: Without lubrication

Table 5. Velocity Factors (K)

| Chain speed m/min | velocity coefficient K |

|---|---|

| 15 or less | 1 |

| 15 ~ 30 | 1.2 |

| 30 ~ 50 | 1.4 |

| 50 ~ 60 | 1.6 |

[Calculation formula]

・SI units (kN)

F = (m1 + m2) S・μ1 + 1.1m2・S・μ2 + m1・S'・μ3 ・ G 1000

- Gravity unit (kgf)

F = (m1 + m2) S・μ1 + 1.1m2・S・μ2 + m1・S'・μ3[Check availability]

Multiply the maximum tension (F) acting on the chain by the speed factor (K) in Table 5 and check whether the following formula is satisfied.

In the case of single-line use

F × K ≦ Maximum allowable load

In the case of Nijo use

0.6F × K ≦ Maximum allowable load

1-2. Calculation of required power

・SI units (kN)

P = F・V 60 × η

- Gravity unit (kgf)

P = F・V 6120 × η