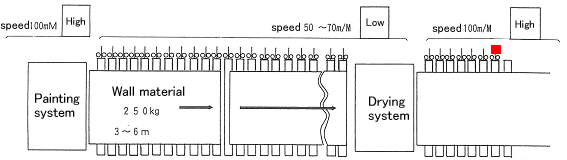

Application Examples Cam Clutch - 23. Painting line for plate materials such as building materials

application

Overrunning

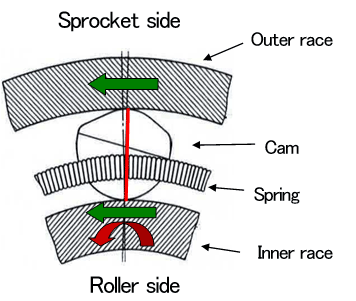

When outer race of the Cam Clutch are engaged and torque is transmitted, the difference in rotation speed and direction of outer race causes

This is a method of use in which the wheel spins freely and repeatedly, similar to the freewheeling motion of a car.

Compatible models

Machines used

Painting line for plate-shaped materials such as building materials

Application Examples

Layout

|

|||||

| ① In the painting area, the exterior wall material passes through the ceramic paint falling like a curtain at a certain speed. | ②The conveyor speed slows down as the material enters the drying oven. | ③ After passing through the drying oven, the exterior wall material is accelerated and sent to the next process. | |||

| *In the ■ section, cam clutches are installed on all rollers and the chain is wrapped around in a zigzag pattern. A sprocket is attached to the outer outer race the cam clutch, and inner race is connected to a roller. |

|||||

- If the speed changes during the painting process, uneven paint will occur.

- When the exterior wall material coming out of the painting area is transferred from the "fast" to the "slow" conveyor, the BB's free rotation allows for smooth movement without slowing down the speed.

- Even when other exterior wall materials are stagnant in front of an exterior wall material that has just come out of the painting area, if the subsequent exterior wall material hits it, the BB will spin freely, pushing the previous exterior wall material, allowing the subsequent exterior wall material to pass through the painting area smoothly.

- As the lift speed gradually slows down and falls below the rotational speed of the tires, the cam clutch engages.

The lift automatically operates at low speed.

Purpose of use and operation explanation

During normal operation

A sprocket is attached to the cam clutch and assembled into each roller. The rotation of the sprocket is transmitted to the outer race the cam clutch, and the engagement of the cam clutch rotates each roller to feed the material.

((Right image: Green arrow)) Meshing is the state in which outer race, cam, and inner race work together to transmit power from the driver to the driven unit. In this example, rotation is transmitted from the outer outer race to the inner inner race through the meshing of the cam clutch.

When transitioning from high speed to low speed and from low speed to high speed rollers

When shifting from the high-speed side to the low-speed side, if the high-speed side pushes the material on the low-speed side, or when transferring from the low-speed side to the high-speed roller and the low-speed roller is pulled by the high-speed side, the cam clutch will enter an idling state, preventing the roller and the transported material from rubbing against each other.

((Right image: Red arrow)) Idling means that even when outer race is stopped, only inner race can rotate in the direction of the red arrow.

Advantages of using a Cam Clutch

- - When moving from high speed to low speed, damage caused by sliding between the material and rollers can be prevented.

- - By utilizing the overrunning function of the Cam Clutch, there is no need to use control equipment.