technical data Large size conveyor chain Smart Replaceable Series Handling

Before installation and removal

1. Precautions

- - When replacing sprockets or tooth replacements, the weight balance may be disturbed, causing the shaft to rotate or the sprocket or tooth replacement to fall. Always ensure that the equipment is securely supported and fixed before carrying out the work. Also, make sure to secure a safe work location and sufficient personnel before proceeding with the work.

- ・When removing the ring tooth type or block tooth type, if you are forced to burn off the bolt due to adhesion or corrosion of the transported material, remove any scratches or deposits on the mounting base seating surface with a file or grinder. It will be easier to remove the bolt if you place a backing plate (rod) with a smaller diameter than the bolt on the bolt and hit it with a hammer.

- - Particularly heavy sprockets and replacement teeth are equipped with hanging holes or eyebolt taps. Please securely fasten them with a sling or wire.

- - Thoroughly clean the sprocket mounting area on the shaft, the divisions of the sprocket body, and the mounting base. If there are any scratches, corrosion, or sticking in the conveying area, remove them with a file or grinder, and finish them smoothly.

2. Mounting bolts

- - When tightening bolts and nuts, tighten them in small increments to ensure even tightening. Use a torque wrench to check the final tightening.

| Bolt size | M10 | M12 | M16 | M20 | M24 | M30 |

|---|---|---|---|---|---|---|

| Tightening torque [N・m] | 68 | 118 | 289 | 568 | 980 | 1960 |

Note: Please use bolts and nuts with strength classification 12.9.

Installation and removal procedures

1. Split type

Installation

- 1. Assemble the split sprockets at the shaft mounting points.

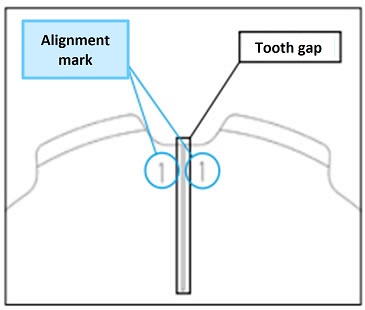

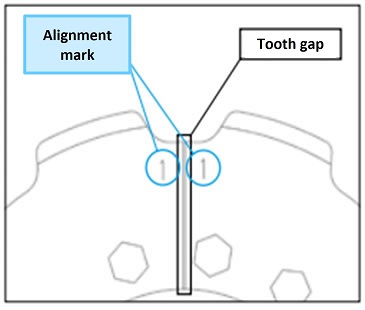

At this time, assemble them so that the alignment marks on the teeth match. - 2. When the split sprockets are assembled, there is no gap on the mounting surface of the hub section, but there is a gap on the mounting surface of the teeth section, but this does not affect the meshing function.

- 3. Use the included spring washers on the bolts and tighten them securely with a torque wrench.

- 4. When installing on the shaft, make sure there is no misalignment between the divided surfaces.

Note: If used with the appropriate tightening torque, it will not loosen in normal environments.

If the product is subject to large vibrations or if it falls and could cause an accident, please use an anti-loosening agent in combination.

2. Ring replacement tooth type

Installation

- 1. Place the replacement tooth on the mounting surface so that the alignment marks are aligned, and temporarily tighten it with the bolts, spring washers, and nuts.

- 2. Adjust the installation gap so that it is uniform. A good guideline for the gap is 1 to 3 mm. This gap will not cause any functional problems when it comes to engagement.

- 3. After installation, adjust the height of tooth root so that they are even.

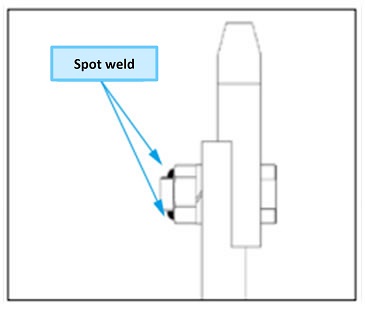

- 4. Please spot weld all nuts in two places to prevent loosening. Sprockets are expected to be used under harsh conditions, including vibration, corrosion, impact, and in a corrosive atmosphere. Please spot weld all nuts to prevent loosening.

Removal

- 1. When removing the replacement tooth, remove the spot welds using a grinder or similar tool.

- 2. Remove the bolt and remove the replacement teeth. If you are unable to remove the nut due to adhesion of the transported material or corrosion of the sprocket, and are forced to take measures such as burning off the bolt, please remove any scratches or deposits on the mounting base seating surface with a file or grinder.

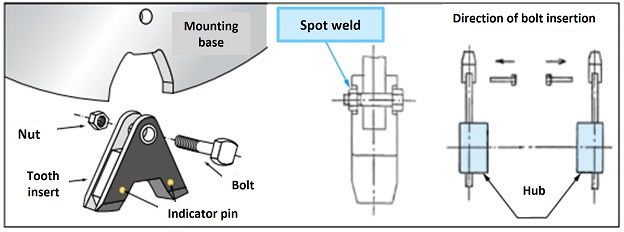

3. Block replacement tooth type

Installation

- 1. Apply the special adhesive (included) to the entire attachment area of the replacement tooth using a spatula or similar tool.

- 2. When assembling the tooth insert into the mounting base, make sure that the tooth insert is in contact with the bottom of the mounting base.

- 3. After checking the contact, tighten the bolts and nuts provided.

Note: When using with a bucket elevator, install the bolts from the inside to the outside of the conveyor.

- 4. All nuts should be spot welded to prevent loosening.

- 5. Leave it like this for about 24 hours to allow the adhesive to dry.

Removal

- 1. When removing the replacement tooth, remove the spot welds using a grinder or similar tool.

- 2. Remove the bolt and remove the replacement teeth. If you are unable to remove the nut due to adhesion of the transported material or corrosion of the sprocket, and are forced to take measures such as burning off the bolt, please remove any scratches or deposits on the mounting base seating surface with a file or grinder.

- 3. Remove the bolt and remove the tooth replacement. Be careful not to let the tooth replacement fall out when removing the bolt.

Indicator pins Inspection

Indicator pins is an option that allows you to determine at a glance when it's time to replace your sprocket. For more information, please click here.

Please check Indicator pins as follows:

1. Inspection Procedure

- 1. If there is any residue on the side of the sprocket, remove it so that Indicator pins can be seen.

- 2. The limit of use is when the abrasion contacts Indicator pins.

- -Indicator pins are embedded in two places on each sprocket (approximately 0° and 180°) on the teeth.

- ・The position of Indicator pins varies depending on the model number. For products with a processed shaft hole, one checker's eye is embedded in the tooth part near the keyway.

2. Precautions

- - If the abrasion part comes into contact with Indicator pins and is continued to be used, the abrasion will be accelerated rapidly. This will also affect the wear of the chain, so please replace it as soon as possible.

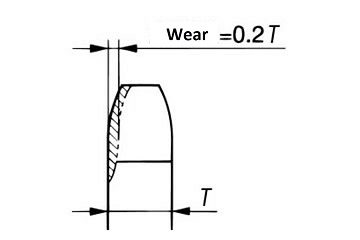

- - If the wear on the face width exceeds 20%, even before it touches Indicator pins, replace the sprocket. Also, if wear is confirmed before it exceeds 20%, re-center the sprocket.

Wear on the sides of the teeth