technical data Top chain Selection

Snapcover Chain Design Document

wearstrip basics

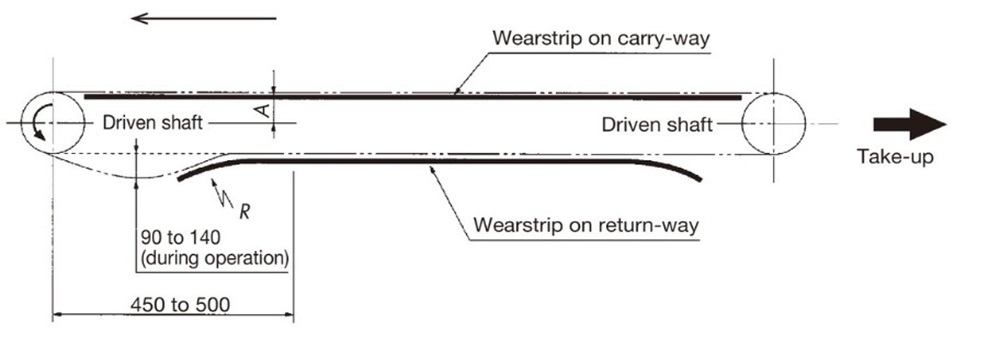

Transport is carried out on the tension side of the chain, and the slack side is supported by wearstrip with gently bent ends to prevent chain vibration and conveyor pulsation.

Chain slack

There should be 90-140 (while running) of slack under the drive sprocket.

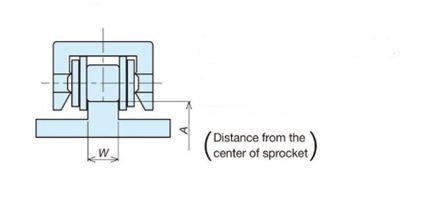

wearstrip height

A = sprocket pitch diameter - roller diameter 2

Bending of wearstrip end

The radius of wearstrip must be larger than the back bend radius R of the chain (see the table below).

| RF06B-SC | RS40-SC | RS50-SC | RS60-SC | RS80-SC | RS100-SC | |

|---|---|---|---|---|---|---|

| Backbend radius R mm | 280 | 380 | 480 | 560 | 740 | 880 |

Chain guide

- - On the conveying side... Always support the load on the chain rollers. Supporting the load on the plastic cover will cause the plastic cover to wear out quickly.

- return-way...Make sure to receive the entire plastic cover.

[Transport side]

Rail width (W):

Generally, this is the sprocket tooth width.

[return-way]

return-way width (X):

Chain width (L) + 2-3mm