technical data Top chain handling

4-3. Determining the sprocket mounting pitch

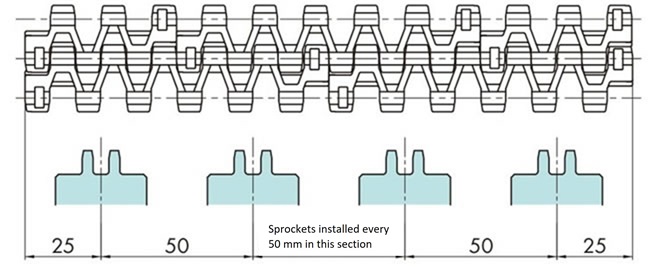

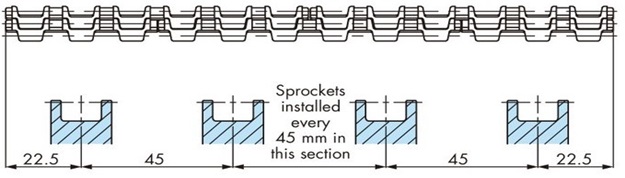

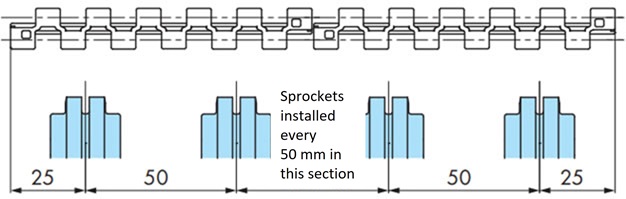

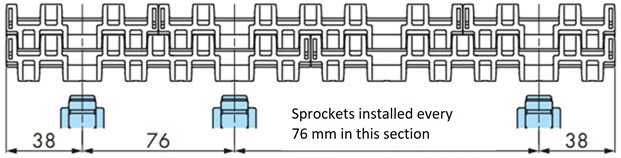

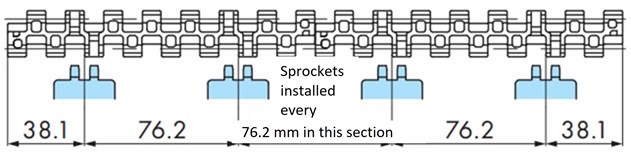

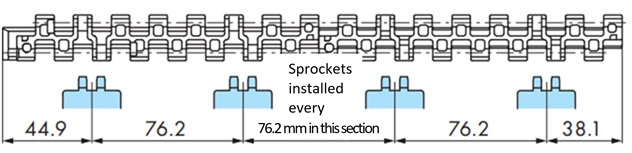

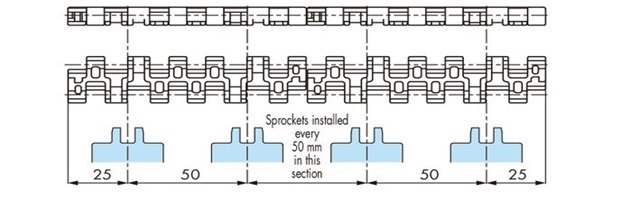

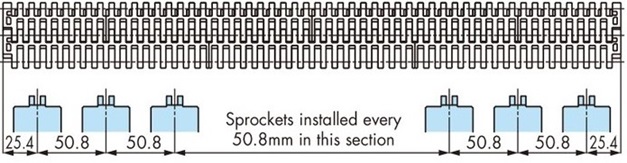

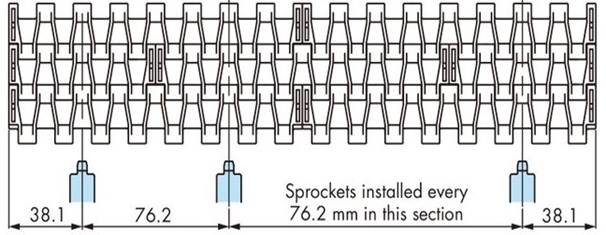

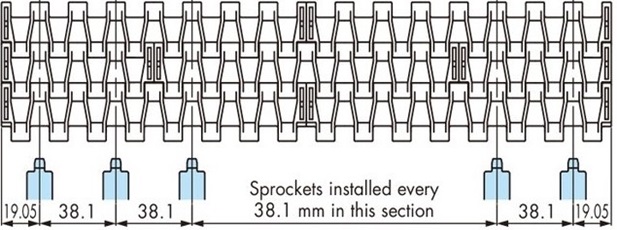

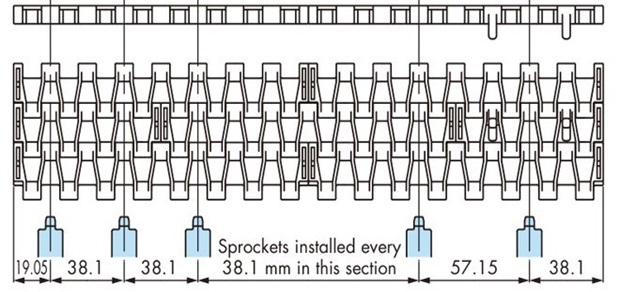

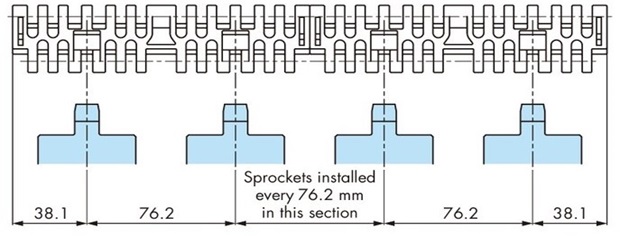

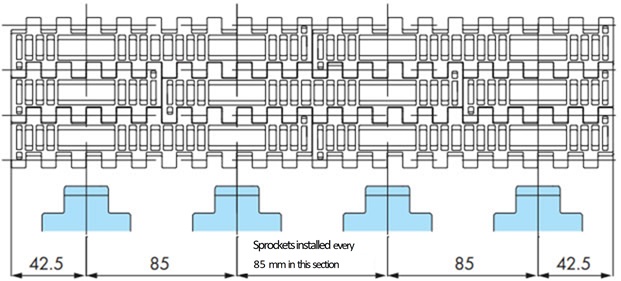

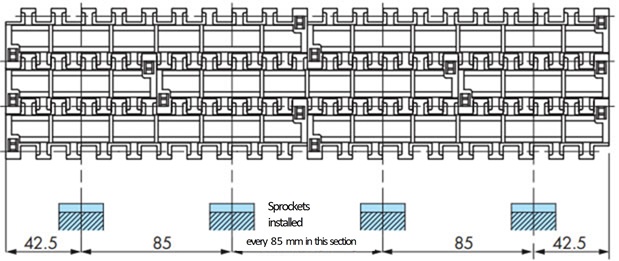

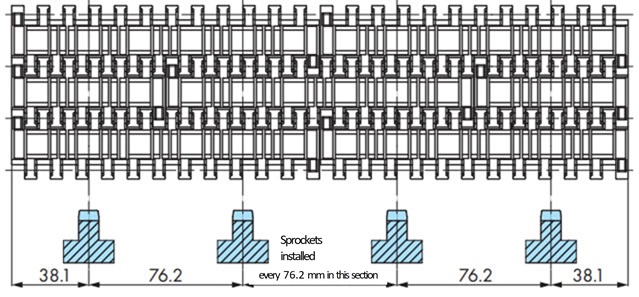

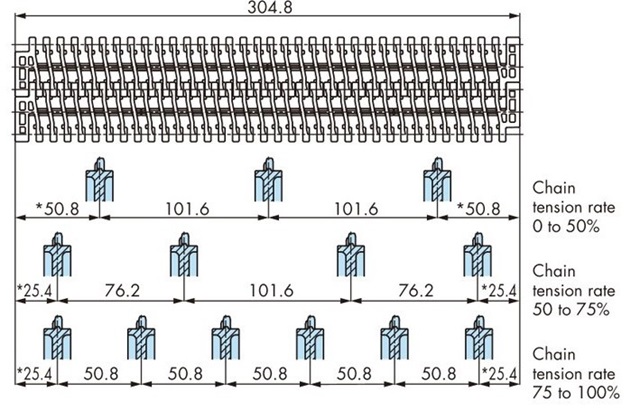

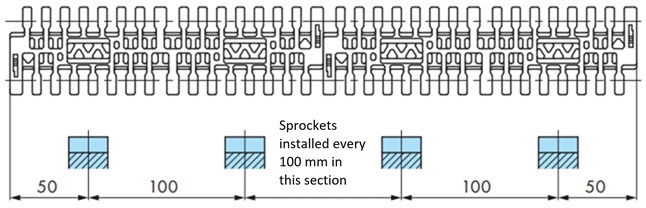

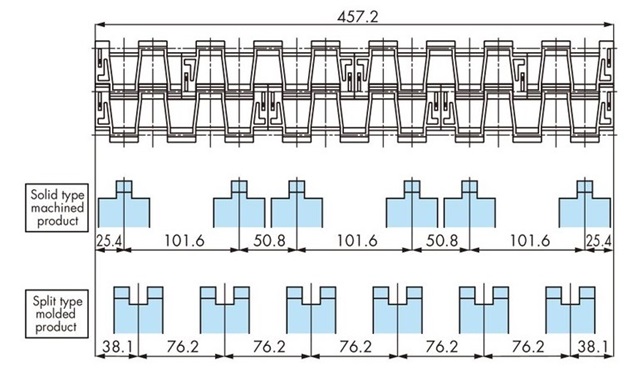

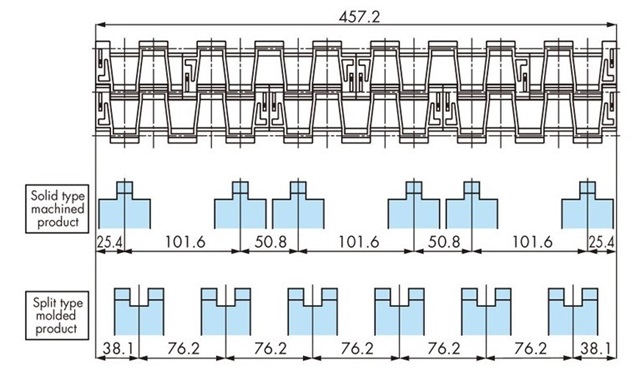

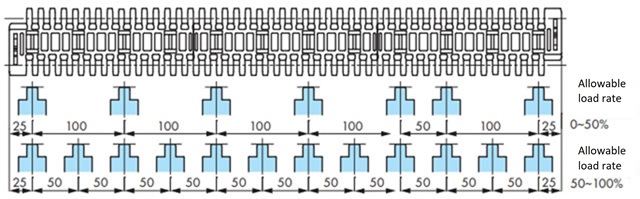

The sprocket mounting pitch diagram for each chain is shown below.

Check what percentage of the chain's allowable tension (MAX per 1m width) is the tension F' calculated for 1m of chain width obtained using formula (2) in step 6.

Please note that this may change depending on the chain tension load rate F1.

Calculation of tension load factor F1 (%)

F1 = 100F' A ...(3)

F'...chain width converted capacity per meter calculated in step 6 kN/m{kgf/m}

A... Chain width 1m conversion capacity kN{kgf} at each operating temperature

Please refer to the chain Allowable load graph.

Wide Type

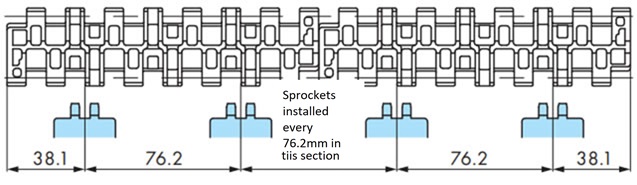

(1) WT0405-W type

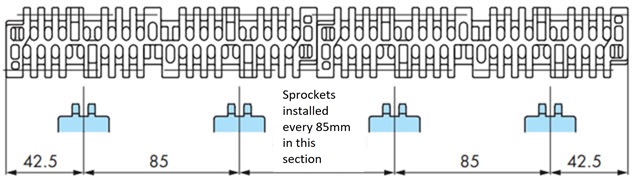

(2) WT0705-W type

(3) BTN5 type, BTN5-A type

Note: The BT5-24T sprocket cannot be used with the BTN5-A (with anti-snaking attachment). Please consider using the BT5-32T. The WT-SW1500-24T can be used.

(4) WT1505-K type, WT1505RN-K type, WT1505G-K type, WT1506-K type

(5) WT1505GTO-K type, WT1505GTORN-K type

(6) WT1515-W, WT1516-W, WT1515G-W, WT1515(T-)FW, WT1516(T-)FW, WT1515VG-W

(7) WT1907-K type

Note: For odd-numbered inch widths, the mounting pitch is 76.2 mm per location. Adjust near the center.

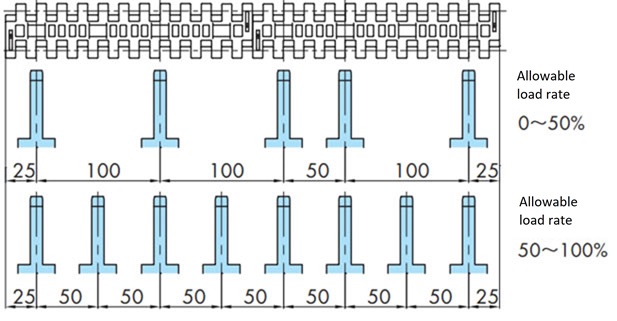

(8) BT6 series, BTC8 type, BTC8-A type

- Sprocket mounting pitch when tension load factor (F1) is 50% or less

(9) BT6 series, BTC8 type

- Sprocket mounting pitch when tension load factor (F1) exceeds 50%

(10)BTC8-A type

- Sprocket mounting pitch when tension load factor (F1) exceeds 50%

(11) WT2505-K type, WT2506-K type, BTM8H type

(12) WT2515-W type, WT2515G-W type, WT2515F-W type

(13)WT2250FG、VG

(14) BTC8S type, WT2525-K type, WT2525VG-K type

(15)WT2705-K type/WT2706-K type

Note)

- 1. *Please be sure to place the sprocket in the position.

- 2. For odd-numbered inch widths, the mounting pitch will be irregular in one location. Adjust it near the center.

(16) WT3005-K type/WT3005G-K type

(17) WT3086-K/WT3086G-K

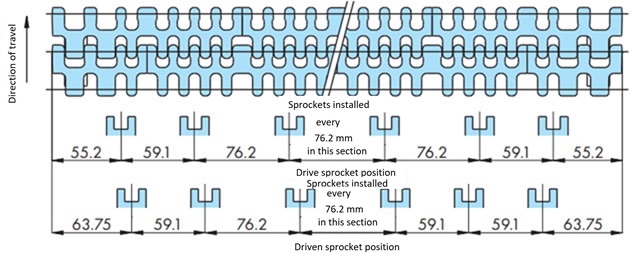

(18) WTU3015T-K type

Note: The drive sprocket and driven sprocket are arranged differently.

(19) WT3109-W type

Note: When sprockets are arranged with an allowable load rate of 0 to 50%, one location will be 50mm apart.

(20)WT3816-K type

(21)WT3827-K type

(22)WT3835-K type

(23) WT3835-T type (with float-preventive tabs)

(24)BTH16

Note: When sprockets are arranged with an allowable load rate of 0 to 50%, one location will be 50mm apart.

(25)WT5707-K type

(26) WT1306-W type