technical data Selecting Small size conveyor chain

Conveyor design considerations

1. Conveyor system and roller type

Table 20

| Conveyor system | Roller type | Different uses |

|---|---|---|

| Roller rolling method (horizontal/tilted)  Double pitch |

R roller type Chain mass: Large Roller allowable load: Large Roller wear: Small |

Smooth operation with little pulsation. Friction resistance is small and power requirement is low. Generally applies to conveyor length of 10m or more or speeds of 20m/min or more. |

Roller rolling method |

S roller type Chain mass: Small Roller allowable load: small |

Generally applies to conveyor length of 10m or less or speeds of 20m/min or less. |

Sliding plate system Double pitch |

It is resistant to the impact of loading and adverse atmospheres, but the rails are damaged quickly. Simple structure. Large power requirement. |

2. Conveyor placement

Table 21

|

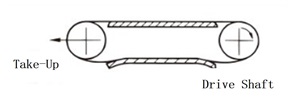

Both the transport side and return side are supported by rails. This is the most logical and recommended layout. Create slack on the outboard side of the drive sprocket. |

|

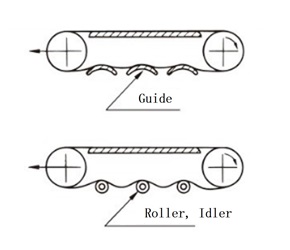

On the return side, the load is received by a guide or roller idler. The chain comes into contact with the guides and rollers and articulate, which accelerates wear and makes it more susceptible to scratches. Chain vibrations can also have a negative effect. Therefore, it is not recommended for long conveyor length. |

|

This method does not support the return side. The tension caused by the mass of the chain on the return side causes vibration, making conveyance uneven. |

Below are examples of commonly used slat conveyors and cross rod conveyors.

Slats are attached using attachment A, and rollers roll on the rails on both the transport side and return side.

This uses a K attachment and is suitable for a larger conveying mass than the one shown above and for wide slat conveyors.

However, on the return side, the chain slides on the rails.

Cross rod conveyor with pipes attached using EP attachments, GNK attachments, or Hollow Pin chain.

Rollers roll on rails on both the transport side and the return side.

3. General-purpose Small size conveyor chain for low and high temperatures

As a general rule, general-purpose Small size conveyor chain should be used in clean air between -10°C and 60°C. If using in an atmosphere other than this, please note the following points.

If the chain is to be cooled or heated, such as in a freezer or in a cold climate, or if it passes through a drying oven or heat treatment furnace, or is affected by heat from transporting high-temperature items, the selection or usage should be changed.The following shows a guideline for the relationship between allowable tension and temperature for Standard Series chains.

Table 22 Ambient temperature and strength

| Ambient temperature ℃ | allowable tension |

|---|---|

| -Up to 30 | allowable tension shown in the catalogue x 1/4 |

| -Up to 20 | 〃 × 1/3 |

| -10 ~ 150 | 〃 × 1 |

| Up to 200 | 〃 × 3/4 |

| Up to 250 | 〃 × 1/2 |

Table 23 Ambient temperature and usage

| Ambient temperature ℃ | How to use | Precautions |

|---|---|---|

| -50 ~ -30 | For temperatures below -30°C, consider using the environment-resistant SS Chain or AS Chain. Standard Series products cannot be used. |

(1) Decrease in impact strength due to low-temperature brittleness of materials (especially Standard Series) (2) Solidification of lubricating oil (3) Rust caused by water droplets (4) Poor bending due to frost |

| -30 ~ -10 | Please allow for a reduction in allowable tension of Standard Series products (see Table 22). | |

| 60 ~ 150 | Change the lubricant. | |

| 150 ~ 250 | Wear resistance will decrease, so increase the chain size to reduce bearing pressure and In the case of Standard Series products, please consider whether or not to use them, taking into account the reduction in allowable tension (see Table 22). |

(1) Increased wear due to decreased hardness (2) Increased elongation due to softening (3) Poor lubrication and poor bending due to deterioration and carbonization of the lubricating oil (4) Increased wear and poor bending due to scale generation |

| 250 ~ 400 | Consider using the environment-resistant SS Chain or AS Chain. |

4. Ambient temperature and lubricant

For ambient temperatures outside the range of -10°C to 60°C, please change the lubricant depending on the temperature, such as for low temperatures or high temperatures. Please see the lubrication section here.

5. Precautions for use in special atmospheres

Please click here.

6. Other Notes

- (1) To keep the conveyor in good condition, install a take-up.

Adjustment length = (center distance × 0.02) + Leeway length

0.02: Allowable chain wear elongation of 2% - (2) Three or more sprocket teeth must be engaged with the chain.

- (3) When using multiple strand, mount the sprockets on the same shaft and align the tooth phase accurately.

- (4) For long conveyor length that use two or more chains in parallel and require particularly high pitch accuracy, we manufacture specially assembled chains to minimize the relative difference in chain length.We also manufacture sprockets with a pair of cut teeth to ensure accurate sprocket tooth phase.

7. Corrosion resistance of environmentally resistant chains and sprockets

Please click here.