technical data Small size conveyor chain Handling

Lubrication

Lubrication is essential to ensure long-term use of your chain. The more demanding the chain's performance becomes, the more important it becomes.

- (1) The purpose of lubrication is to reduce wear on each part of the chain, prevent corrosion (rust), and reduce the required power.

- (2) To prevent the oil from running out, lubricate the unit regularly (about once a week). Lubricate the unit by dripping or brushing the lubricating oil listed below.

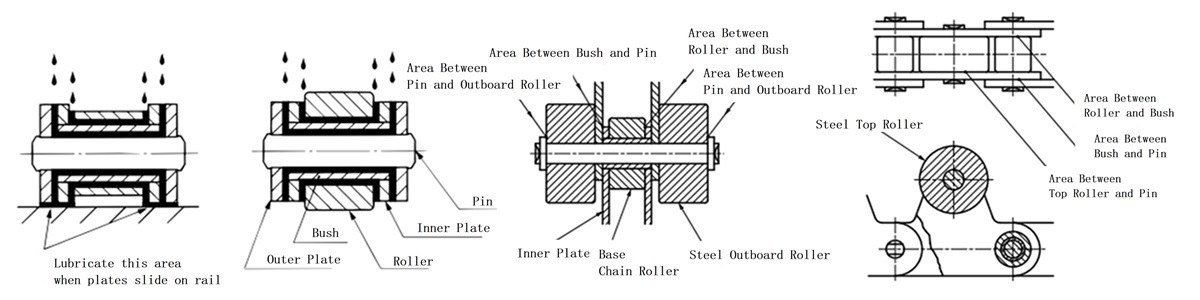

- (3) Lubricating points

Chain elongation due to wear is caused by sliding wear between the pins and bushings, so it is necessary to oil these areas. Also, oil the areas where the rail and chain (plates) slide (see Figure 26).

RS type Double pitch S roller

Double pitch R Roller

Chain with outboard roller

Top roller chain

Figure 26. Lubricating points

Table 25 Lubricating oil SAE number

| Lubrication type | Dripping or brush application | |||

|---|---|---|---|---|

| Chain number | Ambient temperature | |||

| -10℃ ~ 0℃ | 0℃ ~ 40℃ | 40℃ ~ 50℃ | 50℃ ~ 60℃ | |

| Small sizes below RS50, RF2050 | SAE10W | SAE20 | SAE30 | SAE40 |

| RS60~100, RF2060~2100 | SAE20 | SAE30 | SAE40 | SAE50 |

| Large sizes of RS120, RF21200 or larger | SAE30 | SAE40 | SAE50 | |