technical data Clutch Lubrication

Lubrication and Maintenance

Recommended Lubricants and Greases

Proper lubrication is essential for the Cam Clutch to function properly for a long period of time. Follow the instructions below to properly lubricate your Cam Clutch for your application.

1. Cam clutch oil

| Usage | Overrunning or Backstop | Indexing | ||

|---|---|---|---|---|

| 1/3 or less of the allowable rotation speed Ambient temperature below 30°C |

1/3 or more of the allowable rotation speed Or ambient temperature is 30°C or higher |

|||

| Oil brand | Shell Lubricant's Japan | Turbo oil T32, Rimula D10W, Gelco ATF |

Rimura D30 | - |

| ENEOS | DTE Oil Light, Multipurpose ATF, ATF220 FBK Turbine 32, Automatic D2, FBK Oil RO32, RIX Turbine 32, ATFII(N) |

FBK Oil RO68 | - | |

| Idemitsu Kosan | Daphne Turbine Oil 32, Apolloil ATF-DX |

Apolloil Dieselmotive S-330CF | Daphne Oil CR10 | |

| Cosmo Oil Lubricants | Cosmo Turbine Super 32, Cosmo Turbine 32, Cosmo ATF2 |

Cosmo Diesel CF30 | - | |

| Sanwa Chemical | - | - | Samic Arctic Oil Light | |

2. Cam clutch grease

| grease | Applicable clutch | Shell Lubricant's Japan | ENEOS | Kyodo Yushi | ExxonMobil Japan | Cosmo Oil Lubricants |

|---|---|---|---|---|---|---|

| All-purpose grease Li-based | General use | Shellgadus S2 V125J 2 (S), Sunlight Grease 2 |

Martinoc Grease 2 | Unilube No.2 | - | Dynamax Super No. 2 |

| BS Series BR series |

Shellgadus S2 V125J 1 (S), Sunlight Grease 1 |

Martinoc Grease 1 | Multemp PS No.1 | - | Dynamax Super No.1 |

|

| BB Series ML Series |

- | - | - | Beacon 325J | - |

- 1. Avoid using lubricating oils (greases) that contain extreme pressure additives.

- 2. When using the above grease lubrication, the Cam Clutch can function properly within the ambient temperature range of -5°C to 40°C. If the temperature exceeds this range, please contact us.

- 3. Genuine lubricating oil (grease) for cam clutches is available, so please use it.

| Genuine lubricating oil (grease) | capacity | Purpose |

|---|---|---|

| Genuine lubricant for cam clutches | 1L | Overrunning or Backstop (less than 1/3 of the allowable rotation speed) |

| Genuine lubricant for cam clutches (for indexing) |

1L | Indexing |

| Genuine grease for cam clutches | 500g | Ambient operating temperature: -5℃ to 40℃ |

Lubrication type and maintenance

Oil lubrication series products are not shipped with lubricating oil, so please apply the appropriate lubricant before use.

| Series | Lubrication type | maintenance | |

|---|---|---|---|

| MZ・MZ-G・LD MA・BB・ML |

Grease lubrication | Grease is already packed in before shipping. When using the BB series with oil lubrication, use an oil bath and ensure the oil level is above the shaft center. | |

| 200・PB | Grease lubrication | Clean the inside and replace with new grease every six months. | |

| Oil lubrication | Use oil bath lubrication and change the oil every three months. | ||

| MG・MI・MI-S・MR | Oil lubrication | Refill every 100 hours, and drain the old oil once every three months, clean the inside, and then replace with new oil. | |

| MX | Oil lubrication | Every 300 hours, drain the old oil, clean the inside, and then replace it with new oil. | |

| MG-R | Oil lubrication | Refill every 300 hours, and once every three months drain the old oil, clean the inside, and replace with new oil. | |

| BR | Package Type | Grease lubrication | Grease is already packed in before shipping. Refill every three months. |

| Open type | Grease lubrication | Refill every 3 months. | |

| Oil lubrication | Once every six months, drain the old oil, clean the inside, and then replace with new oil. | ||

| BS | 30~135 | Grease lubrication | Grease is already packed in at the time of shipment. |

| 160~350 | Grease lubrication | Once a year, drain the old grease, clean the inside, and then inject new grease. | |

| 425, 450 | Oil lubrication | Refill every three months, and once every six months to one year, drain the old oil, clean the inside, and replace it with new oil. | |

| BS-F | Grease lubrication | Pre-lubricated with grease. Drain and clean inside of the Cam Clutch and inject new grease once a year | |

| OB, TB | オイルバス | Lubrication maintenance is necessary only once a year for normal use | |

Lubrication method

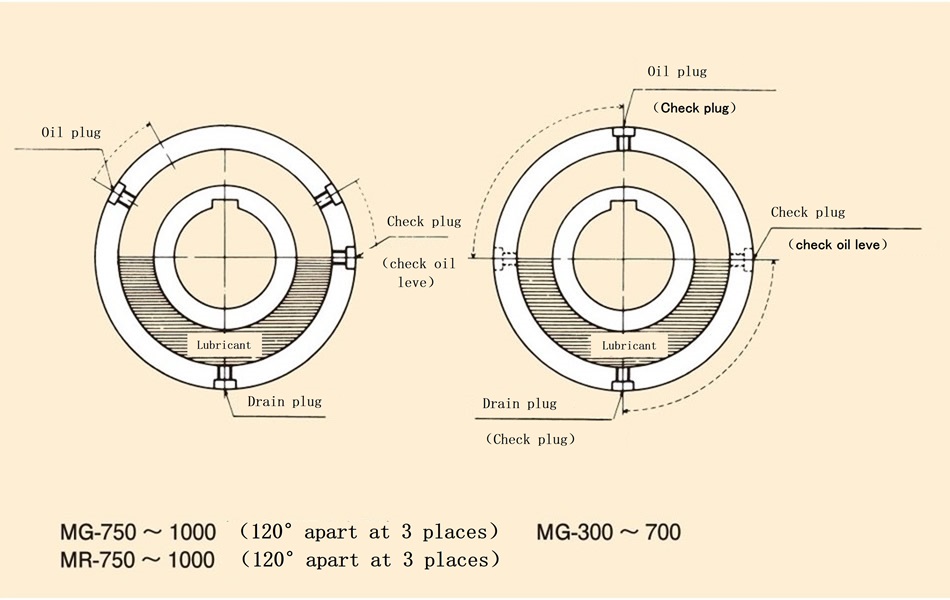

1. How to lubricate the MG.MR series

- 1. In principle, the amount of lubricant should be up to the height of the shaft center for overrunning and backstops.

- 2. Each series has 2 to 4 plugs in outer race.

- 3. If four plugs are available, place each plug in the top, middle and bottom positions, remove the top and middle plugs, and add oil from the top until oil comes out of the middle plug.

- 4. If three plugs are available, place one plug at the bottom and remove the two top plugs, then fill with oil from one of them. Rotate one of the top plugs to the same height as the shaft center and check the oil level.

- 5. If there are only two plugs, remove only the upper plug and add oil through that plug. Then rotate the plug 90 degrees to check that the oil has reached the center of the shaft.

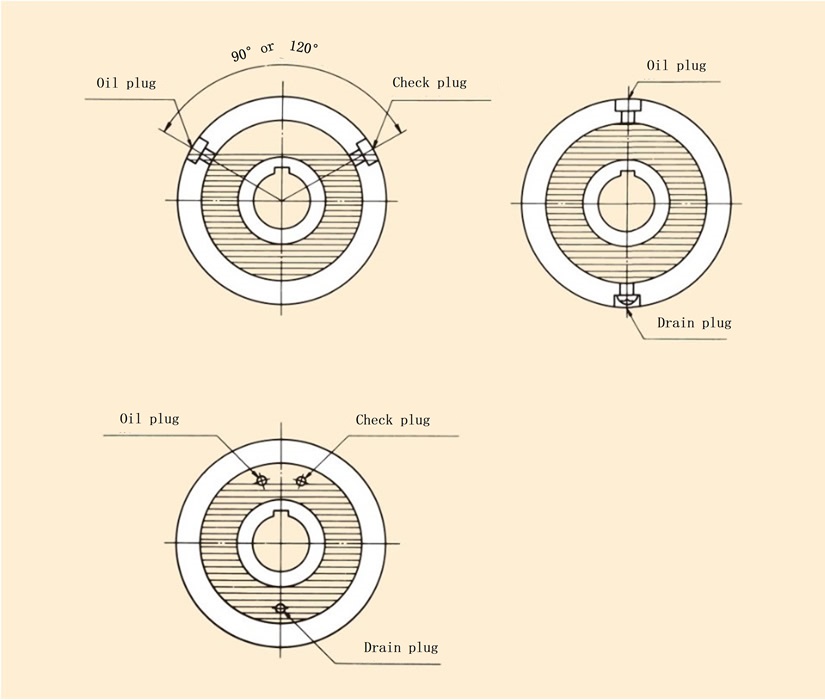

2. How to lubricate the MI.MI-S.MX series

- 1. Fill the tank almost to full capacity.

- 2. There are plugs on the periphery or sides.

- 3. If three or four outer plugs are available, tilt the plugs slightly and add oil until oil comes out of the adjacent plug.

- 4. If two plugs are available, insert the tip of the oiler into the plugs and fill with oil until it overflows.

- 5. If you can use plugs on the side, open both plugs with the side with the two plugs facing up, add oil from one side, and continue adding oil until it starts to overflow from the other side.

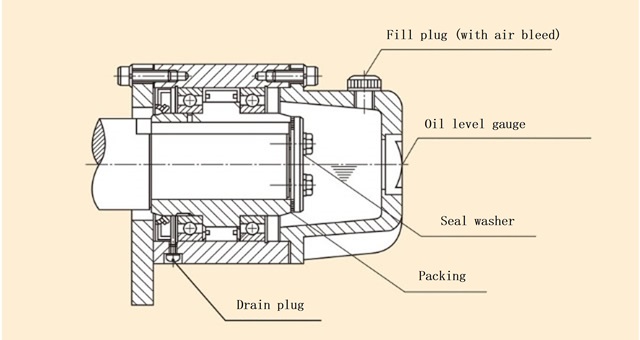

3. How to lubricate the MG-R series

- 1. In principle, the lubricating oil level should be up to the height of the shaft center. Check the level using the round oil level gauge attached to the oil reservoir.

- 2. outer race has plugs in three to four places. One of these plugs should be installed directly below so that it can be used as an oil drain plug. Oil should be supplied from the oil reservoir's oil fill plug. Therefore, install the oil reservoir so that the oil fill plug is directly above.

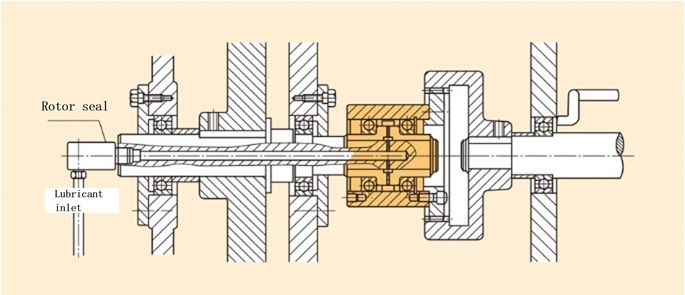

4. Special oiling methods

When a Cam Clutch is used inside a machine, normal maintenance is difficult and a special oiling method is required. An example is shown in the diagram on the left. This method involves installing a through plug on the shaft and forcing oil in through the rotor seal.