technical data Cable Carrier (CABLEVEYOR)-Cable Carrier (CABLEVEYOR) Handling - Cable and Hose Wiring and Maintenance

Cable and hose routing

■Use cables and hoses for transportation that are highly flexible and have excellent durability and ability to withstand repeated bending.

Do not use cables with wire braid coating. Sliding will damage both Cable Carrier (CABLEVEYOR) and the wire braid, so do not use them.

■ Route the cables and hoses without twisting them. Do not pull them out spirally from the drum or coil, as this will result in the cables and hoses being routed in a twisted state. (See Figure 1)

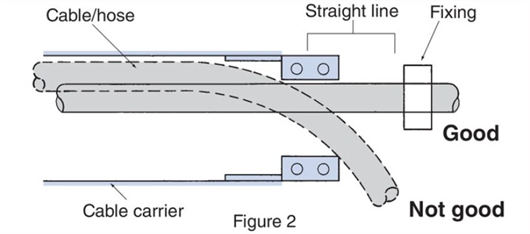

Cables and hoses should be inserted straight into Cable Carrier (CABLEVEYOR) (see Figure 2).

■ Required length of cable/hose

The cable length is usually

It is appropriate to say:

In the case of a hose, the length changes depending on the pressure during use.

It is appropriate to say:

The coefficient 1.015 takes into account hose shrinkage, but this will vary depending on the type of hose, so please check with the hose manufacturer.

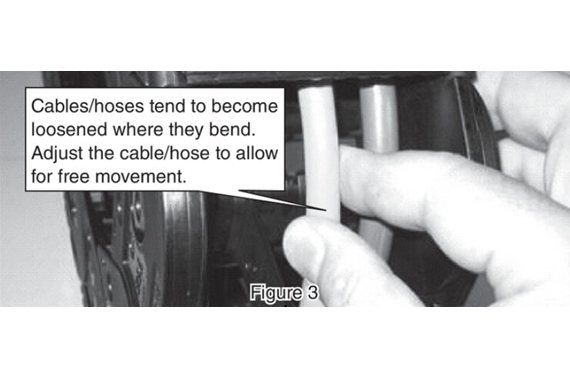

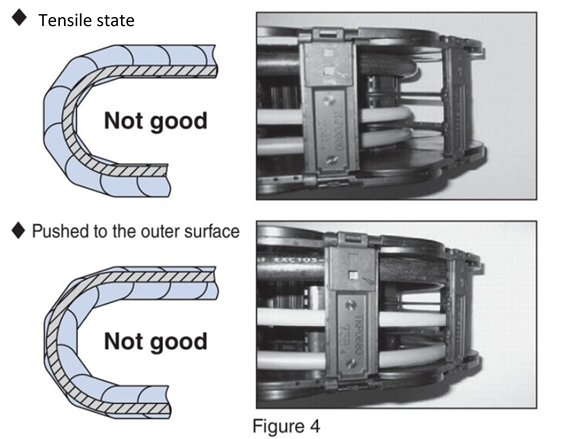

■ Cables and hoses should be routed so that they can move freely and are slightly loose (rather raised above the inner surface of the cable Cable Carrier (CABLEVEYOR)) at bends, and not pulled or pressed against the outer surface of Cable Carrier (CABLEVEYOR) (see Figures 3 and 4).

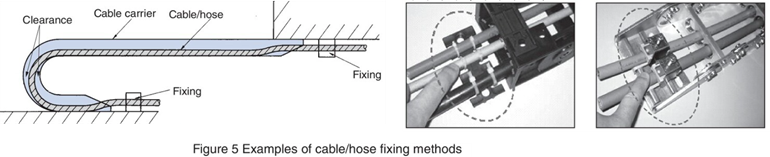

■To prevent unnecessary tension from being applied to cables and hoses, clamp the moving and fixed ends to maintain their length within Cable Carrier (CABLEVEYOR) (see Figure 5).

Do not secure cables or hoses inside Cable Carrier (CABLEVEYOR).

■ Cables and hoses should be arranged in a single row, not stacked. If dividers can be attached, use them to organize the cables and hoses.

■When cables/hoses are divided into multiple sections, the lengths of the cables/hoses will not be the same on the inner and outer periphery. Calculate the required length on the center line of each cable/hose.

However, if cables and hoses are separated into multiple layers, they will be more susceptible to wear due to sliding, so we recommend arranging them in a single horizontal row.

maintenance

■ Bolts on the links and supporters may become loose due to vibrations during transportation or operation, so please inspect them regularly after operation. (TK, TKS, and TKH types)

■ Be careful not to let foreign objects fall or accumulate on guide channel.

■Check regularly to make sure Cable Carrier (CABLEVEYOR) moves back and forth smoothly and that the cables and hoses are not being pulled too hard. Also, if the cable articulate, the internal twist may return and the length may change.