Application Examples Cam Clutch - 16. Vertical Pumps, Vertical Motors

application

Backstop

Also known as backstopping.

The cam clutch continues to run idle while the machine is running, and only engages when the machine reverses direction, which is a rare occurrence.

Compatible models

- ・Special cam clutch

Machines used

Vertical pump, vertical motor

Application Examples

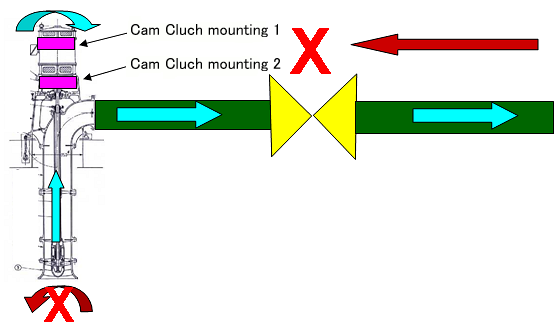

Layout

Purpose of use and operation explanation

Depending on the specifications or intended use, vertical pumps and motors may not be allowed to rotate in reverse.

The above diagram shows an example of a check valve installed. Water flows in the direction of the arrow.

Water flows in the direction of the arrow.

Check valves are designed to prevent water It is used to prevent backflow into the

It is used to prevent backflow into the

If this check valve is damaged, water may flow back and the pump may be forced to reverse at high speed.

There is.

If this type of reverse rotation occurs, it may cause damage to the metal bearing due to loss of lubrication.

there is.

It is effective to install a cam clutch as a reverse prevention device at installation location 1 or 2 in the diagram above.

Ratchets are large in size because each tooth bears the load, which may result in noise such as teeth chipping.

With Tsubaki Cam Clutch...

It is possible to select the appropriate cam clutch based on the mounting location and lubrication method for vertical pumps and vertical motors.

The BR or BR-P series is suitable as a reverse prevention device for vertical pumps or vertical motors that rotate at relatively high speeds.When the pump or motor is running, the cam lifts off (floats up) and is not in contact with outer race, which can be expected to extend its life.

Advantages of using a Cam Clutch

- - The cam clutch spins freely during forward rotation and automatically engages during reverse rotation.

- -Compared to ratchets, it uses many cams to support the load and is more compact.