Application Examples Cam Clutch - 10. Two-Way Conveyor

application

Overrunning

When outer race of the Cam Clutch are engaged and torque is transmitted, the difference in rotation speed and direction of outer race causes

This is a method of use in which the wheel spins freely and repeatedly, similar to the freewheeling motion of a car.

Compatible models

- ・ MZ series, etc.

Machines used

Two-way conveyor

Application Examples

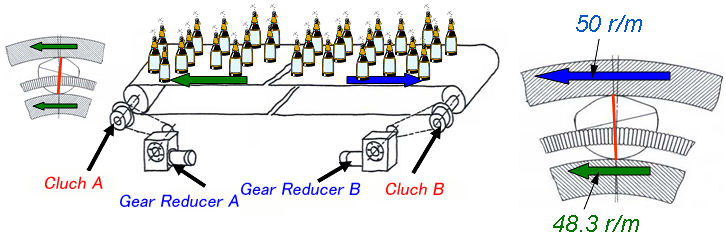

Layout

Purpose of use and operation explanation

This is an example of a cam clutch being used to prevent items from falling over on a conveyor that moves forward and backward like the one above.

Using a cam clutch makes it possible to apply constant tension to the top of the conveyor.

When moving the conveyor in the direction of the green arrow, drive is applied in the same direction to both reducers A and B. At this time, cam clutch A engages, moving the conveyor in the direction of the green arrow.

Next, when moving the conveyor in the direction of the blue arrow, drive both reducers A and B in the opposite direction to the above.

At this time, Cam Clutch B engages and moves the conveyor in the direction of the blue arrow.

When moving in the direction of the green arrow, Cam Clutch A receives a load, but Cam Clutch B does not receive a load and rotates faster by the amount of motor slip. In this situation, a difference in rotation occurs between inner race and outer race of Cam Clutch B, causing the Cam Clutch to spin freely. Cam Clutch A also spins freely when moving in the direction of the blue arrow.

Therefore, the tension side of the conveyor is always constant, preventing the conveyor from sagging.

If a cam clutch is not used, the side not receiving the load will rotate faster than the side receiving the load because there is no motor slippage, causing slack in the conveyor and making it impossible to maintain a constant tension.

In the diagram above, the conveyor is moving in the direction of the green arrow, and the reducer operates the conveyor at 50 rpm via Cam Clutch A. Cam Clutch A carries the load, causing slippage and resulting in 48.3 rpm. Reducer B does not receive the load, so it rotates at 50 rpm, but Cam Clutch B prevents the 50 rpm from being transmitted to the conveyor.

With Tsubaki Cam Clutch...

The cam clutch must be selected based on the mounting shaft diameter, required torque, rotation speed, etc.

You can select a cam clutch that suits your usage conditions, sprocket model number, and installation method.

In addition, you can select specifications that are suitable for your operating conditions, such as when the ambient temperature is high, including lubrication conditions.

Advantages of using a Cam Clutch

- - Cam clutches automatically engage and idle just by changing the rotation speed.

- - Operation can be switched without the need for a device to control idling and meshing.