From Stillness to Movement

Linispeed Jack

New 1.5 ton frame

Jacks go from holding to motion

This innovation was only possible with Tsubaki!

What is required in production sites is to move workpieces accurately and easily.

A compact structure with integrated screws and gears, highly accurate multiple linked operation, and ease of selection to suit your requirements.

What if a jack with such excellent properties could be operated at higher speeds and with higher frequency?

Jacks can only be used at "low speeds and infrequently"...right?

Tsubaki's technology brings innovation to areas that no one has ever imagined or achieved before.

Achieving unprecedented high-speed operation

Jacks enter new territory...

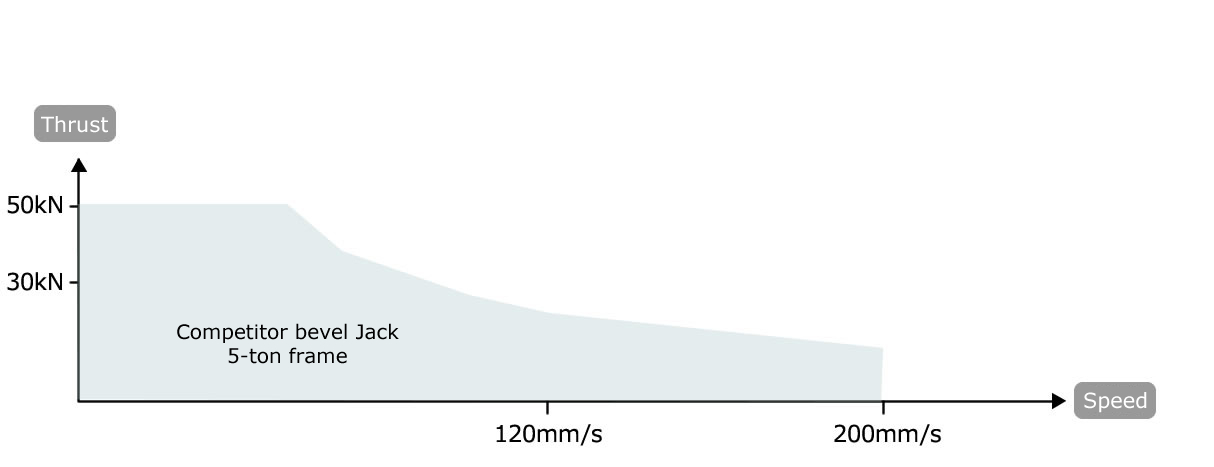

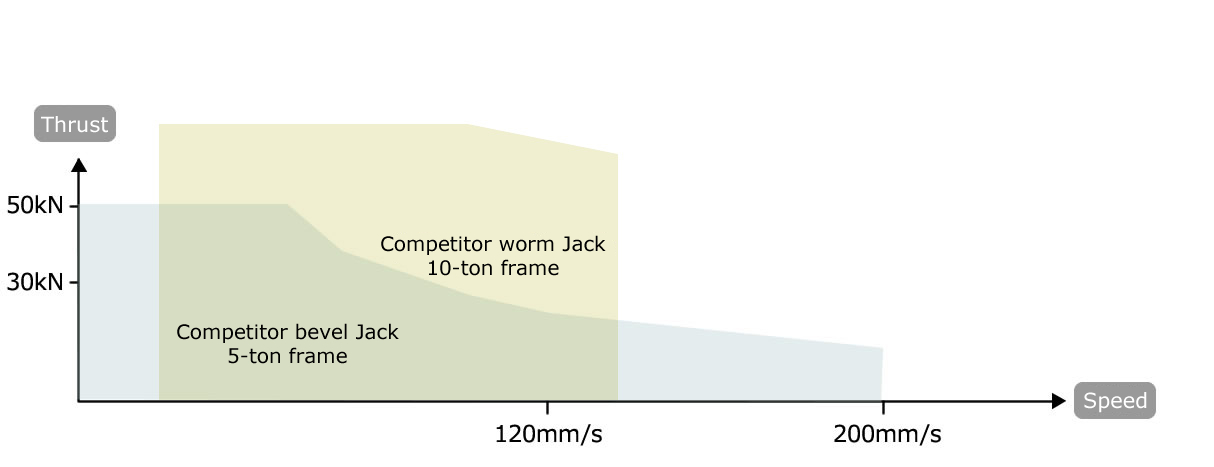

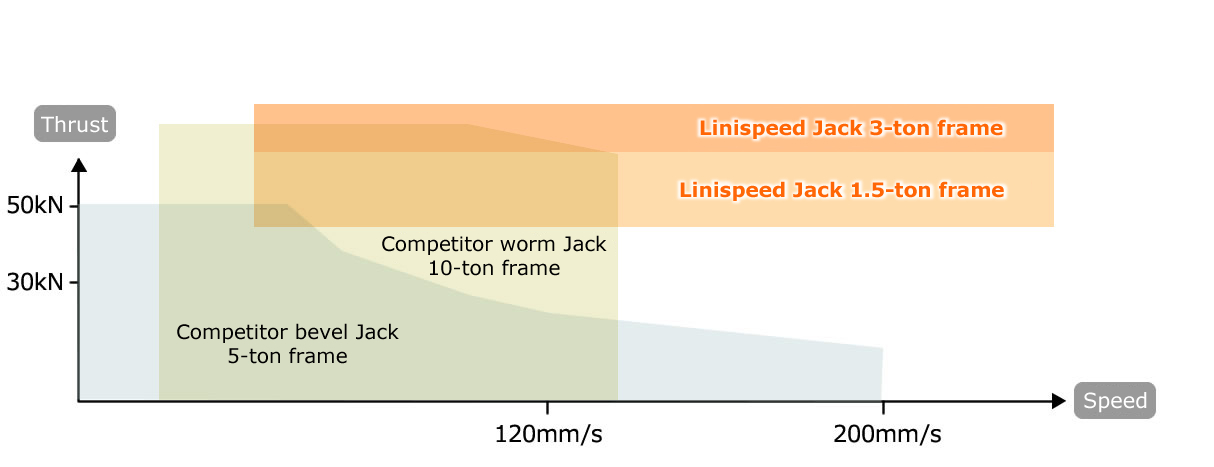

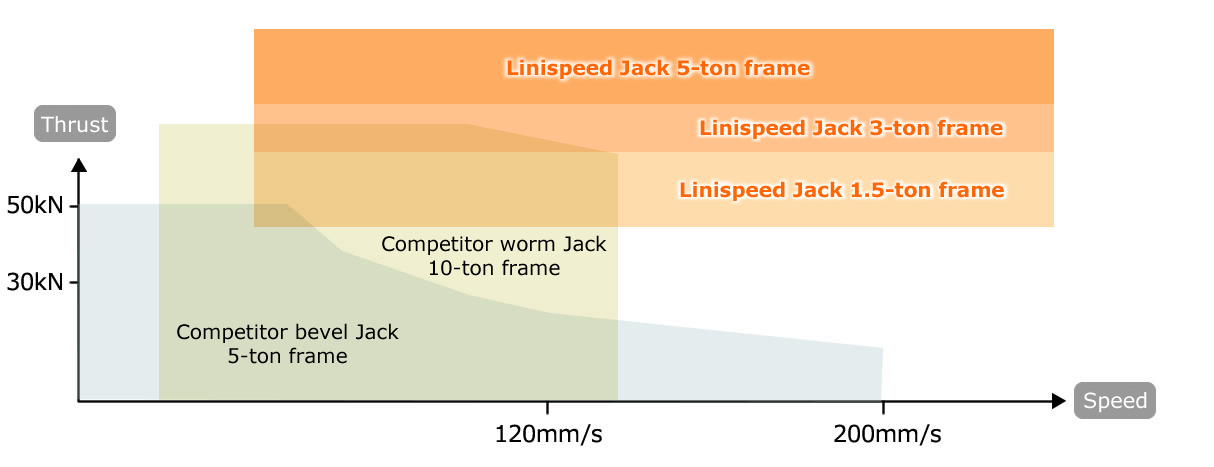

Conventional jacks had a maximum screw shaft speed of 120 mm/s, and the higher the speed, the larger the jack needed to be.

Without increasing the size of the jack

MAX 200 mm/s

Achieves high-speed operation

Linispeed Jack achieves a "constant thrust" that allows it to transport heavy loads at high speeds of 200 mm/s without increasing its size.

Delivers rated thrust up to maximum speed

Thoroughly pursued compact design

It's all about ease of use

Linispeed Jack has been made even more compact by incorporating the ball nut into the gear case. This eliminates the dead space that previously existed due to the height of the nut, allowing for a lower floor. This reduces the overall height of the device, creating more room for lifting and lowering.

Beyond the conventional wisdom of jacks

Achieves high frequency operation

Are jacks not suitable for high-frequency use? There's no need to worry.

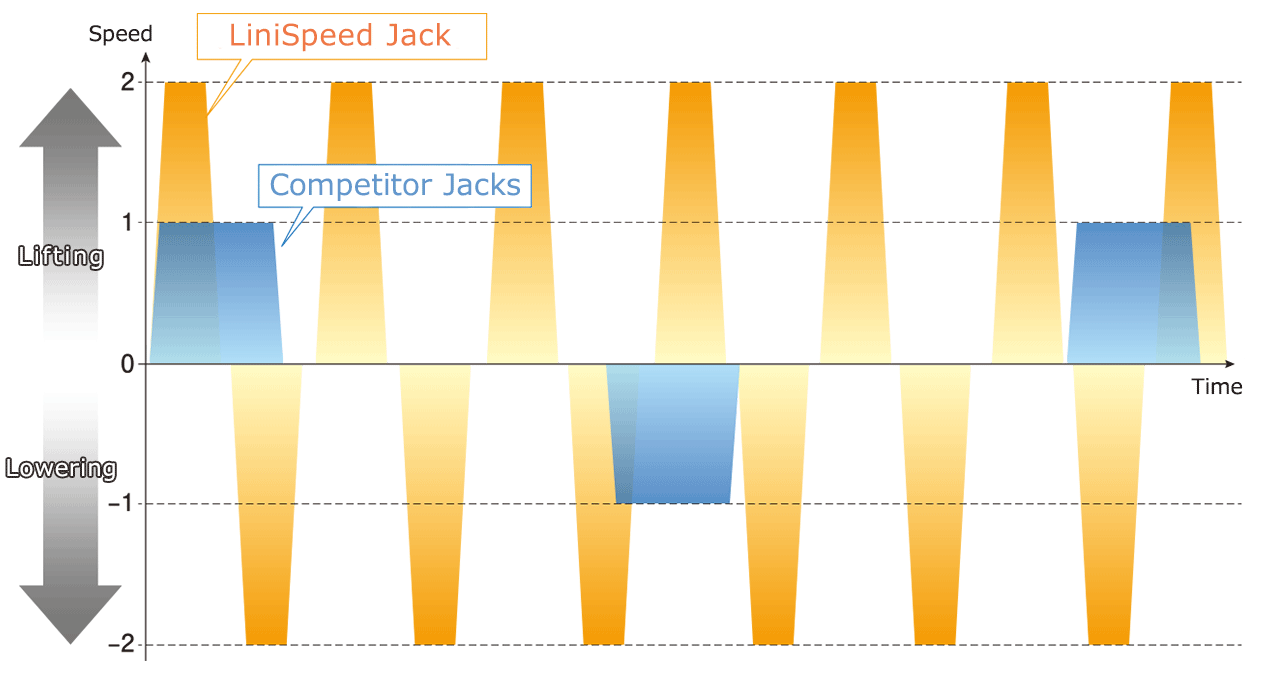

Linispeed Jack contribute greatly to increased productivity with their high-speed, high-frequency operation. Furthermore, they achieve the expected Ball screw travel distance that keeps up with high-frequency operation.

High-speed, high-frequency operation

MAX 100 %ED

Allowable Percentage duty cycle

A maximum allowable Percentage duty cycle of 100% ED has been achieved, enabling continuous operation.

Compared to other companies' products

Tact 5 double

[Operating conditions: ambient temperature 20°C, load 1.5 tons]

*In the case of general lift operation

Expected Ball screw travel distance for high frequency operation

| Expected Ball screw travel distance | ||

|---|---|---|

| SJ030H | Maximum load: 3 tons | When the load is 2 tons |

| 170km (approximately 283,000 round trips with a stroke of 300mm) | 586km (approximately 977,000 round trips with a stroke of 300mm) | |

The jack remains as easy to use as ever!

Various layouts and compactness are possible

Linispeed Jack maintains ease of installation and interlocking operation, while enabling high-speed, high-frequency operation and a low profile.

Furthermore, high-speed input allows the motor and coupling to be made compact.

Tsubaki's 100-year history of expertise will help us meet the needs of production sites that no other jack manufacturer has been able to meet.

Interlocking operation and various layouts are possible

If it's a mechanism other than a jack...

- Selection, assembly and installation effort

- Large installation space

- Interlocking operation is difficult

Ball screw type

rack and pinion

Allowable input speed of 3000 r/min ensures efficient selection

Servo motors and couplings are also compact

Linispeed Jack allows input that matches the rated rotation speed of the servo motor.

It also enables the size of servo motors and couplings to be reduced, contributing to cost reductions for the entire drive unit.

Easy to choose and use

Making jacks simpler and smarter

The Linispeed Jack is capable of high-speed, high-frequency operation, expanding the range of uses to include applications that were previously thought impossible with a jack.

Recruitment history

| Industry | application | Reasons for Selection | ||||

|---|---|---|---|---|---|---|

| FPD/Semiconductor | LCD inspection equipment | High frequency | Quick delivery | |||

| LCD manufacturing equipment | High speed | |||||

| LCD manufacturing equipment | High frequency | |||||

| Cleaning machine | High speed | Low profile | ||||

| Semiconductor Cleaning Machine | High speed | High frequency | Servo drive | |||

| Robot lifting (substrate cleaning) | High speed | Low profile | Servo Synchronization | |||

| Substrate transport | Low profile | Servo Synchronization | ||||

| steel | Steel inspection equipment | High speed | Low profile | |||

| Steel inspection equipment | High speed | Mountability | ||||

| Coater (coil lifting) | High speed | |||||

| Heating furnace steel bar extraction | High speed | long life | ||||

| metal processing | Spring manufacturing equipment | High frequency | Servo Synchronization | |||

| Coil material trimming device | Low profile | |||||

| Pipe Manufacturing Equipment | High speed | High frequency | long life | |||

| Pipe Manufacturing Equipment | High speed | High frequency | Low profile | long life | ||

| Large steel plate transfer device | High speed | Servo Synchronization | ||||

| induction hardening equipment | High speed | Servo drive | Position accuracy | |||

| induction hardening equipment | High speed | Low profile | Servo drive | Position accuracy | ||

| Copper plate elevator | High speed | Servo drive | ||||

| car | Pallet transfer device | High speed | High frequency | Low profile | long life | |

| For raising and lowering heating devices | High speed | Low profile | ||||

| Continuous casting equipment | High frequency | Low profile | ||||

| Brake container lifting | High speed | High frequency | Servo Synchronization | |||

| Car electromagnetic wave inspection device | High speed | Quick delivery | ||||

| Other dedicated machines | silencer device | High speed | Multi-point positioning | |||

| Motor Core Press | High speed | High frequency | Servo Synchronization | |||

| Carbon rod manufacturing equipment | High speed | |||||

| Roll Coater | High frequency | Servo Synchronization | ||||

| Cable Tensile Tester | Servo Synchronization | |||||

| Bottle sorter | High speed | High frequency | Servo drive | |||

| Vehicle coupling test equipment | Low profile | Servo Synchronization | ||||

| Mold Feeder | High speed | High frequency | Multi-point positioning | |||

| Agricultural machinery inspection equipment | High speed | Low profile | Servo Synchronization | |||