Plastic Modular

On the chain

Introducing a curved conveyor!

Resolves various problems with curved conveyance

Straight and curved transport layout possible

Do you have problems with curved belt conveyance, such as "frayed edges" and "time-consuming maintenance," or with metal mesh belts, such as "metal powder generation" and "wanting to avoid metal contact"?

In response to customer requests, Tsubaki has added a new Plastic modular chain to its lineup for curved conveyance.

Plastic modular chain features such as easy maintenance with partial repairs and an attachment to prevent meandering, enabling efficient conveyance in a variety of curved layouts, including 90-degree, 180-degree, and S-curve layouts.

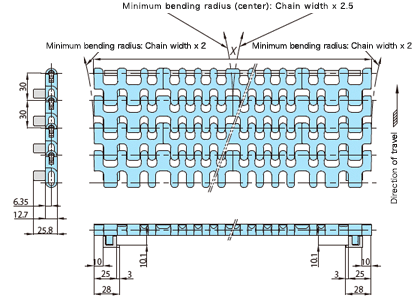

Features of Plastic modular chain for curved conveyance (WTU3015T-K type)

Various curve layouts possible

- Note: Conveyor frames are not supported.

90 degree curve

180 degree curve

S-curve

Easy maintenance such as chain cut and connect and repair

A plug that is easy to cut and connect and connect is used to prevent the main body pin from coming loose.It can be cut and connect connected with just a flat-head screwdriver, making maintenance easier than metal mesh belts or flat belts.

Disassemble in just 5 steps and connect in 4 steps

Disassembly Procedure

Place a thin flat-head screwdriver or similar tool on the plug on the side of the chain.

Use a lever to remove the plug from the main unit, being careful not to let the plug fly off.

Remove the plug on the opposite side of the chain as in steps 1 and 2.

Insert a screwdriver or similar tool into the chain pin hole from the other side and push the pin out.

Grab the exposed pin and pull it out of the chain to disassemble it.

Consolidation Procedure

When connecting chains, insert the plug on the other side. Pull the chains together to combine them, and insert the pin from the front.

Next, insert a plug to close the pin insertion area.

When doing this, be sure to pay attention to the orientation of the plug and push it in until you hear a click.

Check that the plug is installed correctly.

- Note: When connecting, please use the included or dedicated pins.

float-preventive tabs (tab) is made with ultra-Low Friction / Wear resistant (ALF) specifications, reducing the coefficient of dynamic friction with the rail.

float-preventive tabs (tab) is made with Ultra-Low Friction / Wear resistant (ALF) specifications to reduce the coefficient of dynamic friction with the rail. Reducing sliding resistance also reduces the acting tension and saves energy. It also suppresses the generation of Wear debris under dry conditions.

Recommended industries/application examples for Plastic modular chain for curved conveyance (WTU3015T-K type)

logistics industry

Bakery industry

can manufacturing industry

beverage industry

- Note: This product may not be suitable for use depending on the speed, transported items, weight, environment, application, etc. Please contact us if you have other applications or conditions.

Plastic modular chain for curved conveyance

Product lineup