Tsubaki Small size conveyor chain Integrated Attachment Chain

The optimal shape for transport

Custom-made

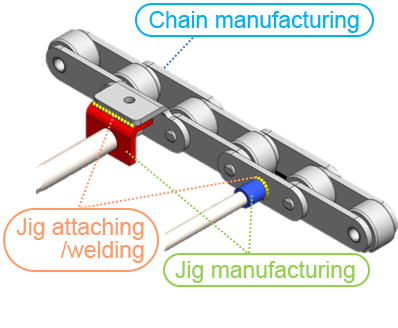

What is Integrated Attachment Chain?

Integrated Attachment Chain is a Tsubaki chain with special attachments that integrates the chain with a jig that can be installed by the customer.

Rather than adding the jig (attachment) later, it is manufactured by incorporating it into the chain in advance.

Before

After

Before the introduction of Integrated Attachment Chain

Chain production, jig production, and installation work are each handled by different companies.

Process management is complicated and costs are high.

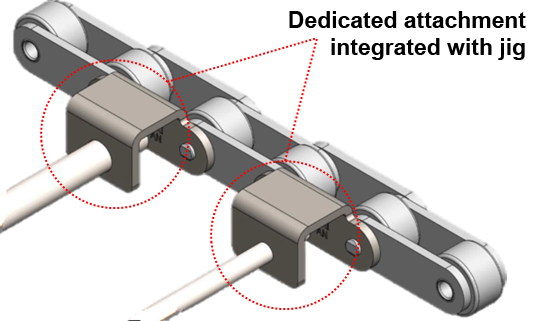

After the introduction of Integrated Attachment Chain

All unified under Tsubaki!

We propose optimal solutions for all aspects of process, cost, and design!

Significantly reduced effort and costs

Tsubaki can handle all the jig manufacturing and installation, helping to reduce costs!

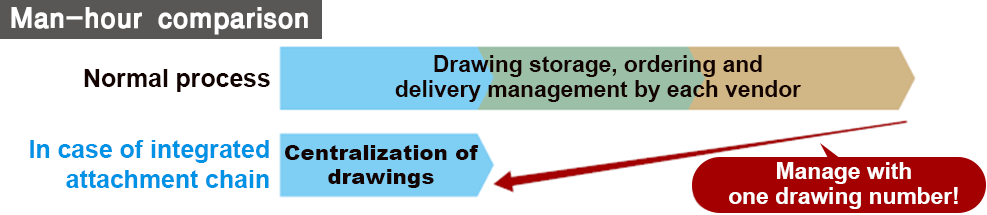

Tsubaki manages all drawings centrally by drawing number, so your next order will go smoothly.

All inquiries regarding delivery and specifications can be handled by Tsubaki.

Three application patterns for Integrated Attachment Chain

Tsubaki Integrated Attachment Chain can be manufactured in the following three patterns to meet customer needs.

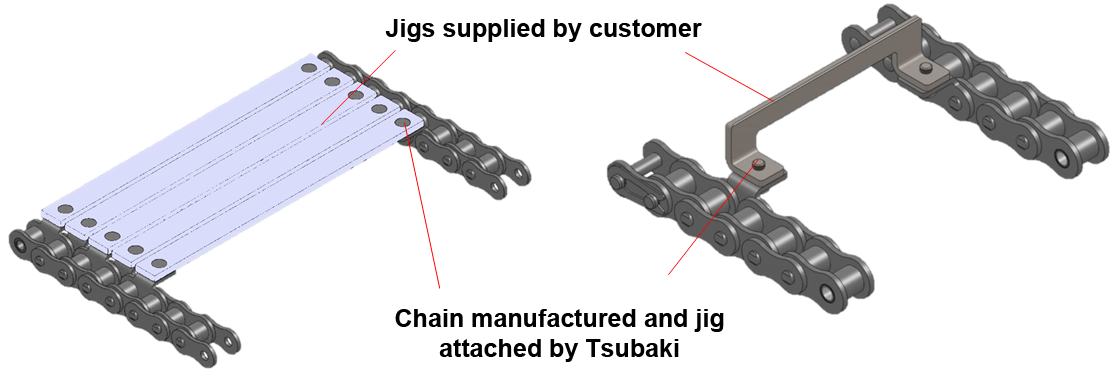

- Pattern 1: Jig supply

- We receive the jig made by the customer and attach it to the chain.

- Pattern 2: Jig production

- The jig and chain are made together and attached to the chain.

- Pattern 3: Integrated jig

- The jig and chain are manufactured as an integrated unit.

Case studies

Pattern 1: Jig supply or Pattern 2: Jig production

Customers can now provide jigs such as slats and scrapers that they would previously have manufactured and installed themselves, and we will install the jigs when manufacturing the chain. We can also manufacture jigs ourselves. By outsourcing the entire process of jig manufacturing, jig installation, and chain manufacturing to us, customers can significantly reduce the number of jig manufacturing and installation costs and man-hours required.

Pattern 3: Integrated jig Custom-made optimal shape

Laser processing eliminates the need for molds, so even small lot production is possible.

Before

After

Unlike the conventional method of creating a jig by machining and then attaching it to the chain, the attachments for Integrated Attachment Chain can be created using a laser processing machine.

Since there is no need to create complex molds, we can also handle small lot orders.

We can reduce mold costs for prototype projects and deliver special-shaped chains at relatively low prices.

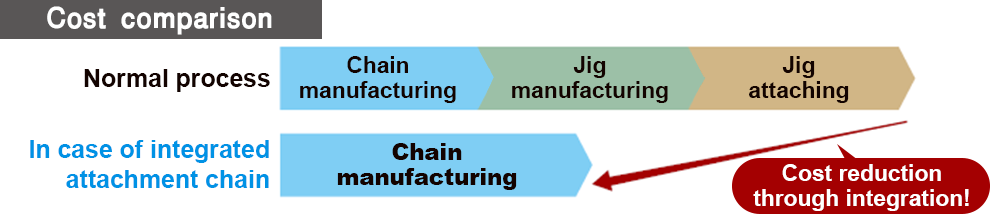

No jig manufacturing or assembly work required... This reduces total costs

Before

After

When attaching a jig to a chain, it takes time and effort to create the jig using sheet metal processing and then attach it to the chain with bolts and nuts.

Because Integrated Attachment Chain is integrated with the jig, customers can reduce their total costs, including jig processing costs and assembly man-hours.

No welding required as it is an integrated unit... so the jig will not come off

Before

After

If a customer welds and attaches a jig to Small size conveyor chain, the jig may come off.

By integrating jigs and attachments into Integrated Attachment Chain tailored to your transport needs, you no longer need to weld the chain yourself. Because there are no welds, there is no risk of the weld coming loose during transport.

Before

After

Not only does a loose weld require repair, but in the case of food processing machinery, it can also lead to the introduction of foreign matter, so this method reduces the number of welding steps and prevents foreign matter from entering. Compared to welding, it also improves the accuracy of the jig mounting position.