technical data Small size conveyor chain Sprockets Handling

Inspection

During the initial break-in period, please inspect the following items as necessary to make adjustments.

- (1) Abnormal wear of the chain.

- (2) Chain slack.

- (3) Chain pulsation and jerking.

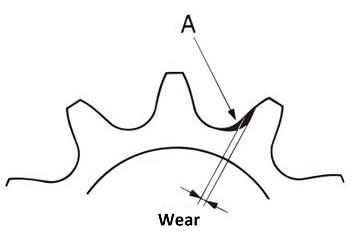

- (4) Abnormal wear on the sprocket, abnormal contact marks due to runout, or accumulation of dirt on the sprocket tooth root. When the sprockets are properly engaged, they are evenly contacting as shown in the diagram at A. If they are unevenly contacting as shown at B, this is due to improper installation of the sprocket or a twisted chain, so please re-inspect. The normal contact position should be slightly above tooth root (valley). However, if initial tension is applied and tension remains on the slack side, there will be slight contact with tooth root (valley), but even in this case, the strongest contact will be at position A. In the case of idlers and tighteners, the contact will be at the center of tooth root (valley).

Figure 28. Sprocket tooth contact

- (5) Excessive wear of guide channel.

- (6) Abnormality in the lubrication system.

-Causes of chain pulsation, jerking, and abnormal wear

- (1) Overload or jamming of debris.

- (2) Backbending of the chain on the return trip.

- (3) Insufficient or no lubrication.

- (4) Sprocket wear.

- (5) Irregular wear or breakage of the chain.

Usage limit

When the sprocket wears down as shown in the diagram below (left), the chain gets caught in part A, making it difficult to release, causing the chain to vibrate.

The amount of wear tolerance varies slightly depending on the conveyor type and chain size, but if the chain is replaced when it has worn down to about 0.3mm to 1.0mm, it will not be damaged.

Also, if the sprocket is worn in the tooth width direction as shown in the diagram below (right), the shaft is not centered correctly and should be corrected.

Figure 32. Sprocket tooth wear