technical data Large size conveyor chain Sprockets Handling

1. Installation

The quality of sprocket installation has a significant impact on the smooth operation of the conveyor and determines the lifespan of the conveyor chain. Please install correctly according to the following instructions.

Installation accuracy is a general value seen from the perspective of the conveyor chain itself. If there are limitations on the accuracy of the conveyor itself, please comply with those limitations.

1.1 Shaft installation accuracy

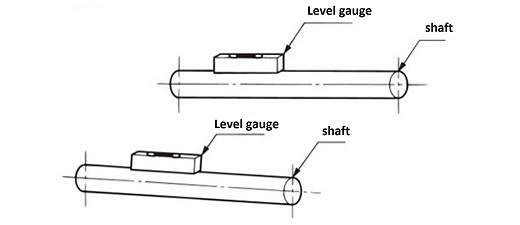

1.1.1 Shaft levelness

Use a spirit level to adjust the accuracy to within ±1/300.

Figure 1. Measuring the horizontality of the shaft

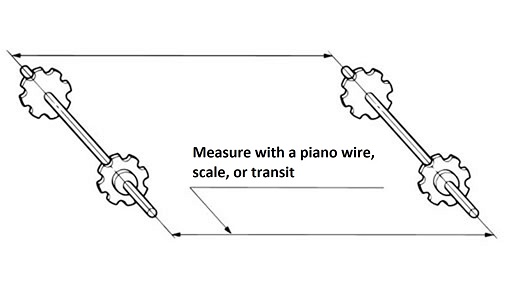

1.1.2 Shaft parallelism

Use a scale or similar tool to adjust the parallelism of the shaft to within ±1 mm.

Figure 2. Measuring the parallelism of shafts

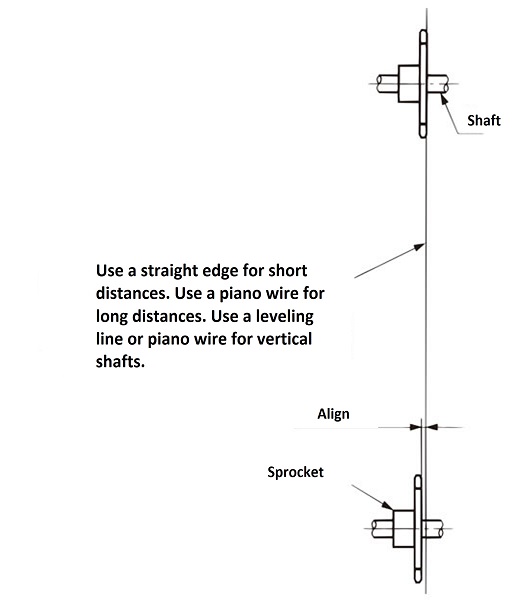

1.1.3 Misalignment of a pair of sprockets

- ・Up to 1m center distance: ±1mm or less

- ・When the center distance is between 1m and less than 10m: ± center distance (mm)1000 or less

- ・When the center distance is 10m or more: ±10mm or less

Figure 3. Measuring sprocket misalignment

1.1.4 Fixing the sprocket

Once the sprocket is correctly positioned, secure it to the shaft using a key or similar tool.

Parallel use sprockets have two or more pairs of sprocket teeth on the same shaft that are in phase with each other.

If parallel use is specified and the key is processed by our company, a match mark will be stamping on the hub.

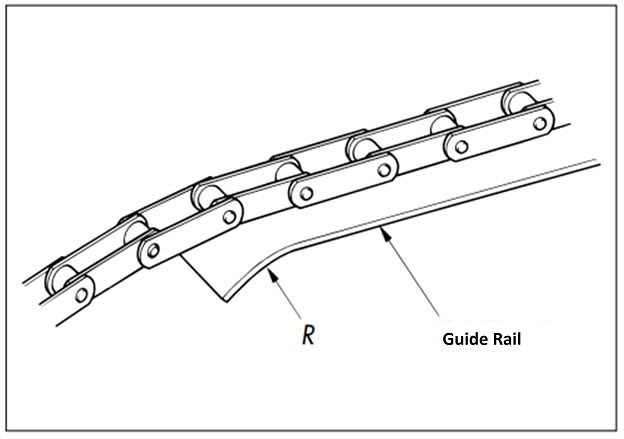

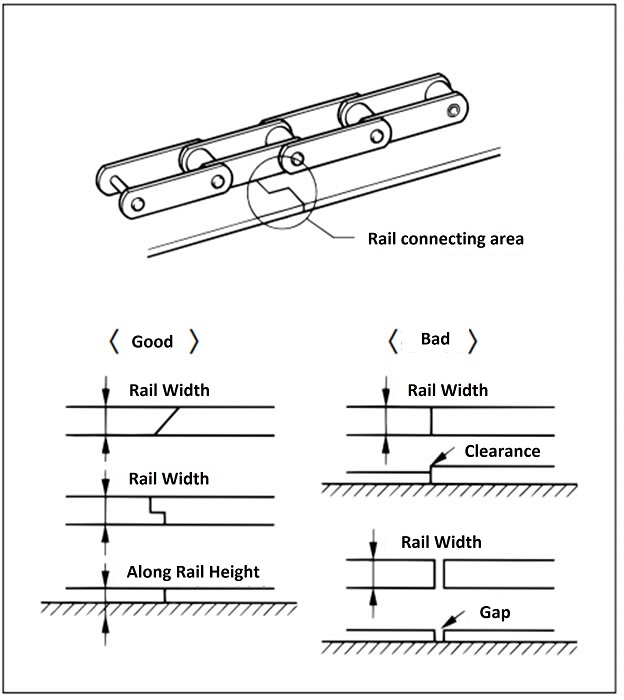

1.2 Conveyor chain rails

- 1) Make the rail joints smooth as shown in the diagram below. Remove any edges and eliminate any steps or gaps.

- 2) Remove any spatter or scale that may have formed during welding.

- 3) During a test run, oil the chain with no load and check the condition of the chain and rail.

- 4) Chain entrance/exit

guide channel is rounded to ensure smooth chain movement.

Rail joint

Chain entrance/exit guide channel