technical data linear actuator Power Cylinder

Installation and Maintenance: U Series

Installation

Installation direction

Horizontal, vertical, tilt, etc.

Installation environment

- All models have a fully enclosed structure that allows them to be used outdoors. However, even outdoor models require an appropriate cover in adverse environments where they are constantly exposed to water or steam, or in places where snow accumulates. Ambient temperatures vary depending on the conditions of use, but they can generally be used within the range of -15 to 40°C. If they are used above 40°C, be sure to protect them with an insulating cover or similar. Never use in a flammable atmosphere. Doing so may result in an explosion or fire. Also, avoid use in locations where they are subject to vibrations or impacts exceeding 1G.

- - When using cabtyre cables or lead wire-equipped models outdoors, be sure to take adequate waterproofing measures.

Installation method

- - Use a trunnion mount or clevis mount to install the main body. Attach the tip with an I-shaped End fitting.

- - For trunnion mounting, apply grease to the trunnion pin and trunnion hole. Also apply grease to the connecting pin of End fitting and the connecting pin when mounting a clevis.

- - If the main body vibrates significantly when the cylinder is activated, please consider using plain bearings or rolling bearings at the connecting parts.

If you require a plain bearing installed in the trunnion hole, please contact us. - - If the trunnion pin or the connecting pin of the clevis and End fitting faces vertically (when the cylinder is laid on its side) and the body oscillates, take measures to prevent wear such as inserting plain bearing material into the trunnion hole, clevis fitting, or side of End fitting.

Figure 1 Installation method

Trunnion Mount

Clevis Mount

*For mounting hardware, please refer to the options section.

manual operation

To adjust the stroke manually, release the brake on the brake-equipped motor, then turn the manual handle shaft of the reduction section with an adjustable wrench or socket wrench.

| caveat |

If a load is applied to the rod, remove the load before releasing the brake. |

|---|

Please refer to the standard model list (here) for the rod travel distance per rotation of the manual shaft.

Rod rotation prevention

- 1. The rod generates a rotational force (see here) as a result of the thrust, so it is necessary to prevent rotation. The rod rotational force at rated thrust is listed in the model list. In most cases, it is possible to prevent rotation by attaching the end of the rod to the driven machine.

- 2. When moving the tip freely or when attaching a pulley to pull a rope, etc., it is usually necessary to prevent the rod from rotating. If you require Power Cylinder with a rotation stopper, please contact us. Note that the LS rod of the external limit switch unit cannot be used to prevent rotation.

Lateral load on the rod

Install the rod so that no bending load (lateral load) is applied to it.

If a load is applied perpendicular to the rod (lateral load) or in an eccentric load direction (eccentric load), take the following measures.

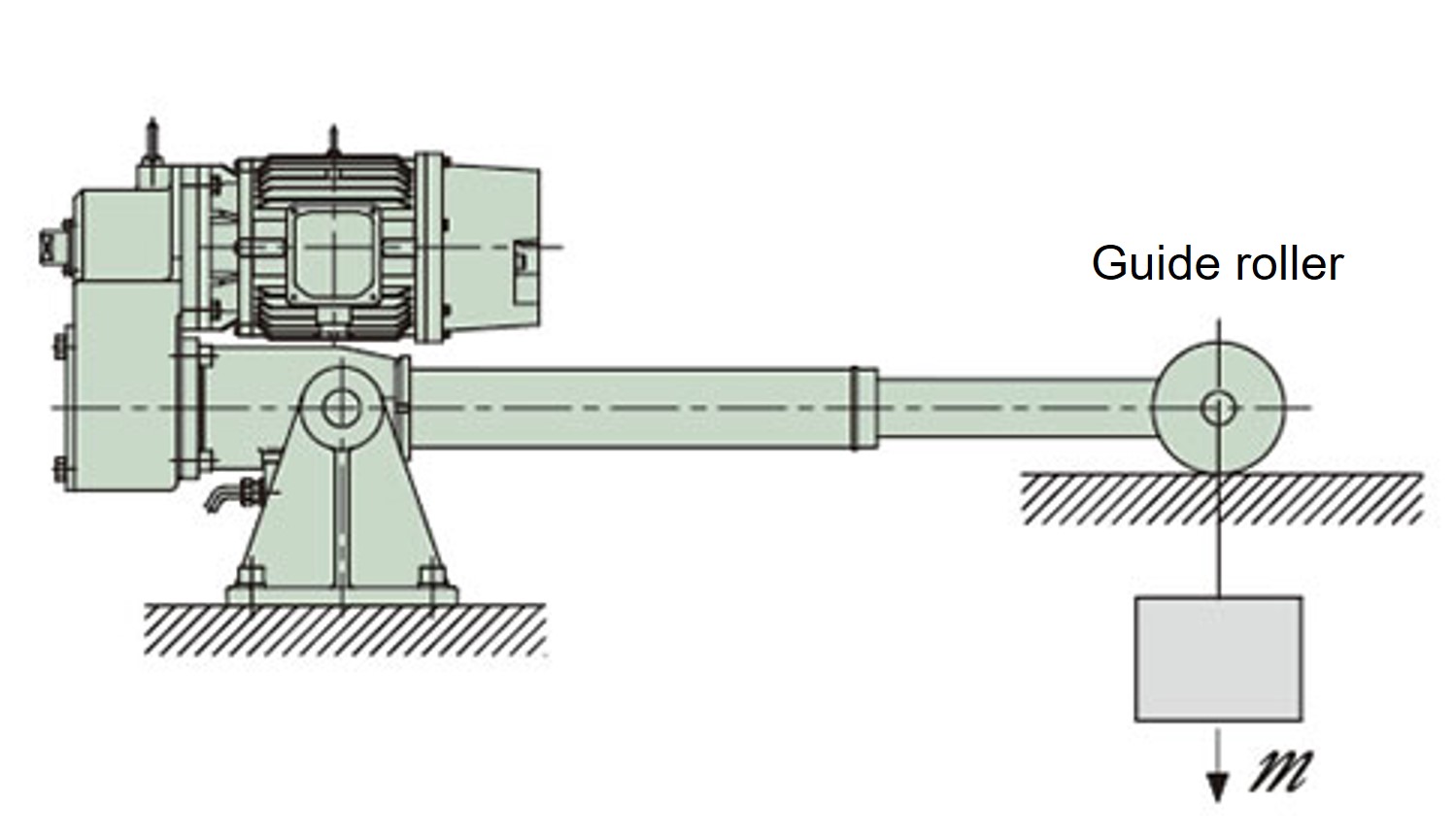

(1) Lateral load: Install guide rollers on the rod (Fig. 2).

Figure 2 Lateral load

To avoid applying a lateral load directly to the rod, provide guide rollers, etc.

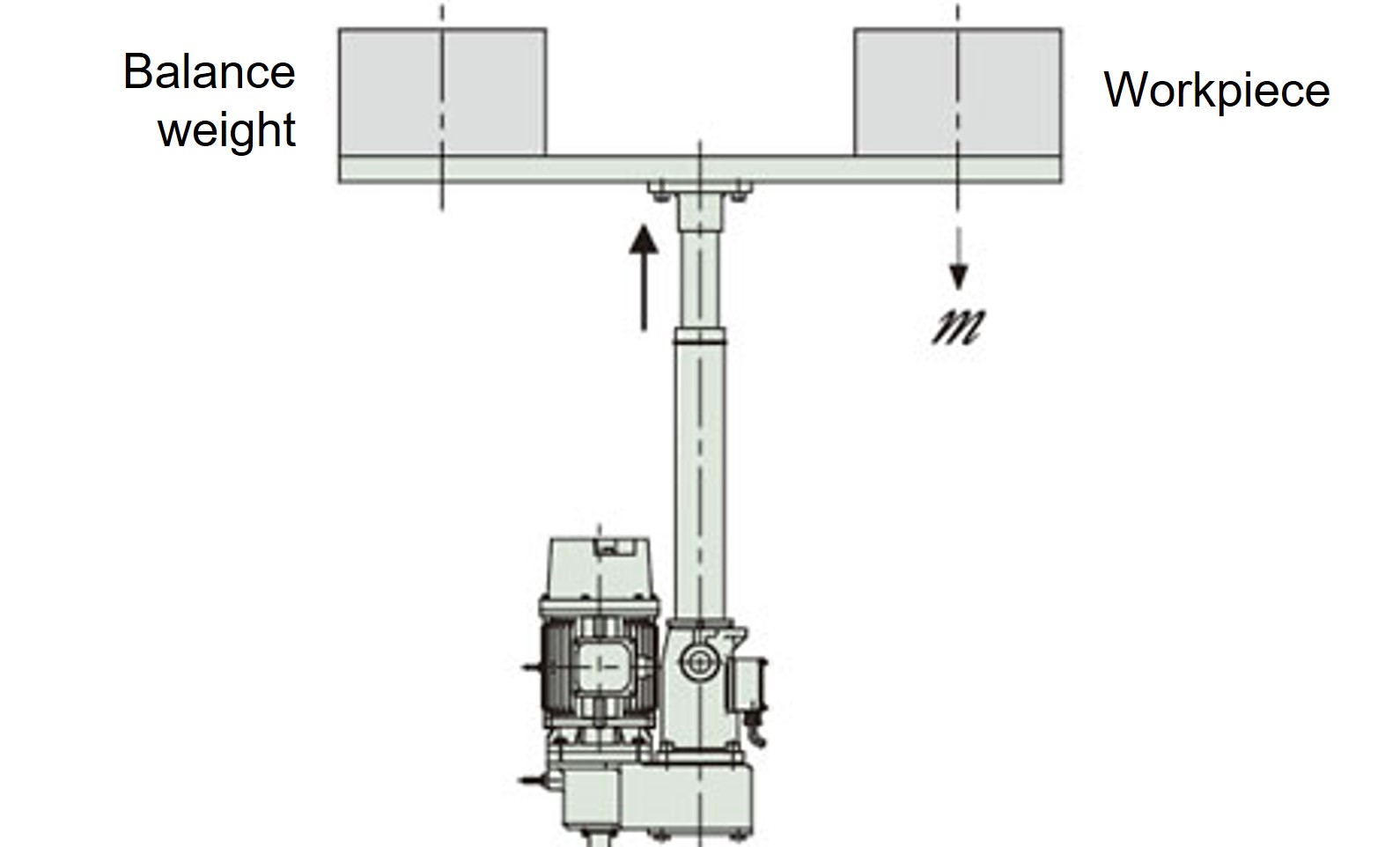

(2) Eccentric load: Use a balance weight, etc. (Fig. 3)

Figure 3 Eccentric load

If an eccentric load is applied, provide a balance weight or similar.

*A separate guide is required for this layout.

About Megger testing

This cylinder is strictly prohibited from Megger testing as it may damage the built-in power module. However, if you wish to perform Megger testing on the external circuit, please remove the brake wiring from the terminal box.

Stroke adjustment external LS (optional) setting

- - An option to attach a limit switch to Power Cylinder body is available, so please use it.

- - Use limit switches to regulate both ends of the stroke.

- ・Please use within the stroke range. If the stroke is exceeded, damage may occur.

- - When adjusting the limit switch, please take into account the coasting distance (here).

- When using the entire nominal stroke, set the limit switch so that the cylinder stops within the XA dimension in the dimension table.

- ・At H speed, the coasting distance is long, so there is a possibility that the striker will go over the limit switch. For this reason, be sure to operate the limit signal in the control circuit with self-holding.

- ・Please be sure to wire the C-type thrust detection limit switch before use. Operating it without wiring may cause damage.

- ・Never adjust the C-type thrust detection limit switch yourself, as this may result in a large deviation in the thrust detection setting.

maintenance

Ball screw lubrication

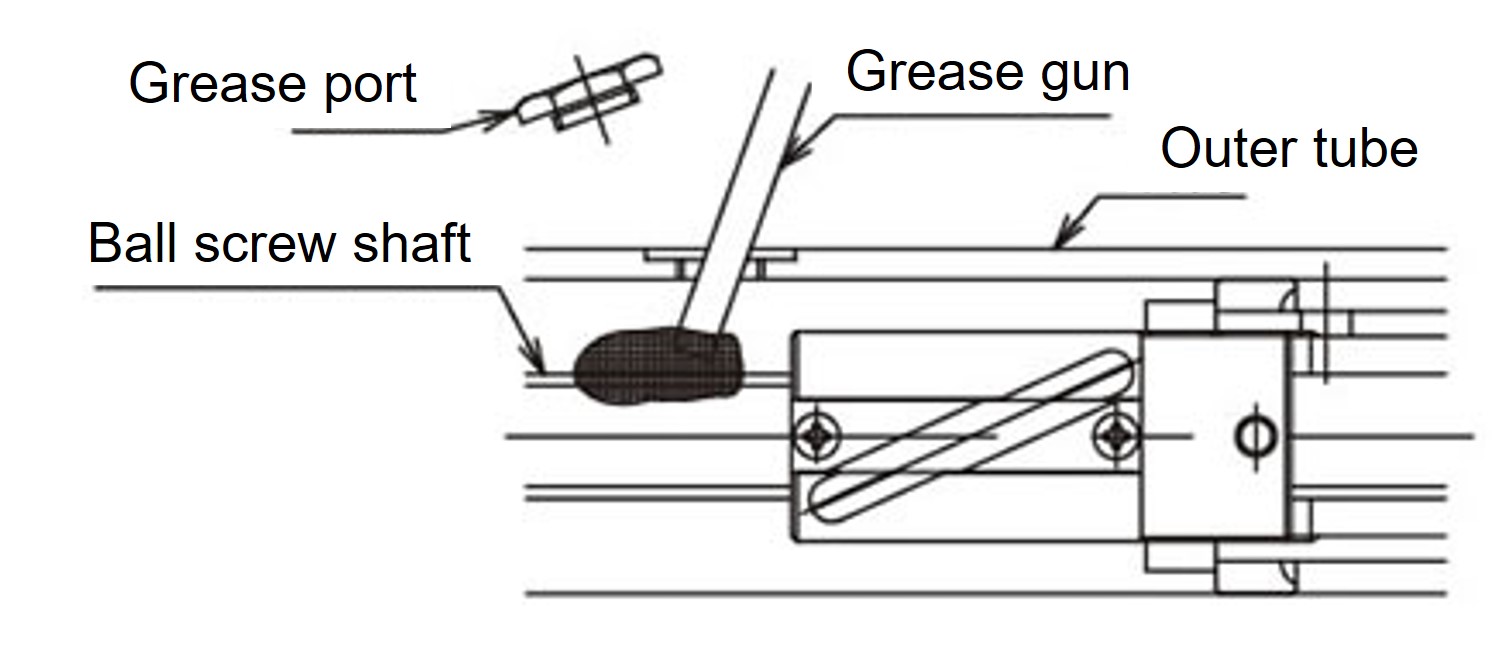

Ball screw is pre-lubricated with grease, so use it as is. Use Tables 1 and 2 as a guide for adding grease. To grease Ball screw screw, remove the greasing port bolt on the outer cylinder, advance the rod a full stroke, apply grease to the outer circumference of the screw with a grease gun, and then move it back and forth within the stroke range you will be using. Repeat this action 2 to 3 times.

The total amount of grease to be applied at one time is approximately 10 to 15 g per 100 mm of stroke (U6000), and approximately 30 to 35 g per 100 mm of stroke (U8000 to U50000).

| caveat |

Never insert your fingers into the grease port. |

|---|

Table 1 Special grease

| Usage category | Ball screw |

|---|---|

| Manufacturer | Exxon Mobil |

| Grease name | Mobil SHC Grease 681WT |

*This grease is specifically designed for Power Cylinder U series. Do not use other greases.

| caveat |

If any grease other than the dedicated grease is used, the cylinder life will be significantly reduced. |

|---|

Table 2. Grease cycle

| Frequency of use | Grease Cycle |

|---|---|

| 1001 round trips/day or more | Every 1 to 3 months |

| 501-1000 round trips/day | Every 3 to 6 months |

| 101-500 round trips/day | Every 6 months to 1 year |

| ~100 round trips/day or less | Every 1 to 1.5 years |

*The values in the table above are intended to allow for longer use, and do not indicate the lifespan.

Greasing the reducer

The gears and bearings in the reduction section are pre-lubricated with grease and are therefore not required to be lubricated.

Initial grease application to reducer

- Gear case: Daphne Eponex SR No.1

- Planetary reduction part: Moly gear grease No.1