technical data linear actuator Power Cylinder Selection

Selection: G Series

Requirements

Machines and methods used

Thrust or load N{kgf}

Stroke mm

Speed mm/s

Frequency of use Number of starts/min

Usage time (hours/day) and annual operating days (days/year)

The nature of the load on the machine used

Usage environment

Power supply voltage, frequency

Selection Procedure

Deciding the model STEP1

Please decide the type (A, B or C) based on the environment and method of use.

Deciding the model number STEP 2

- (1) Calculate the annual travel distance based on the stroke, frequency of use, and duration of use.

Annual travel distance km = Actual stroke m × frequency of use times/day × number of operating days/year × 10-3

- (2) Refer to Table 1 to determine Service factor based on the load characteristics and the machine being used.

- (3) Multiply the thrust or load by Service factor to obtain the corrected thrust.

- (4) Based on the corrected thrust and annual travel distance, determine the frame number from the "Expected travel distance" at the bottom of this page, then select the applicable model number from the list of standard models (here) based on the stroke, speed, power supply voltage and frequency.

Table 1 Service factor

| Load Nature | Examples of machines used | Service factor |

|---|---|---|

| Smooth operation without shocks small inertia |

Damper and valve opening and closing Conveyor switching device |

1.0~1.3 |

| Operation with light shock During inertia |

Opening and closing hopper gates, various transfer devices, lifting and lowering of various lifters | 1.3~1.5 |

| Operation with large shocks and vibrations Large inertia |

Heavy-duty transport by cart, buffer for belt conveyor, reversing opening and closing device for large lid | 1.5~3.0 |

Note: The above Service factor are general guidelines and should be determined taking into consideration the conditions of use.

Checking the characteristics STEP 3

- (1) Use the product at or below the allowable frequency (Table 2).

- (2) Check Percentage duty cycle.

- (3) Check the coasting distance and stopping accuracy in Table 3 below.

Table 2 Permissible frequency of use

| Series Name | LPG |

|---|---|

| Allowable startup frequency | 10 times/min or less |

| Percentage duty cycle (%ED) | 25 |

Note) Percentage duty cycle is the percentage of operation time per 10 minutes, based on 10 minutes.

The allowable operating frequency of Power Cylinder G Series is within the range that satisfies the number of starts and Percentage duty cycle shown in the table above. Percentage duty cycle is expressed by the following formula.

Percentage duty cycle (%ED) = Operation time per cycle Operation time per cycle + Down time x 100%

Table 3 Coasting distance and stopping accuracy (reference values) (assuming a relay time lag of 0.03 seconds)

| Model number | How to use | ||||||||

|---|---|---|---|---|---|---|---|---|---|

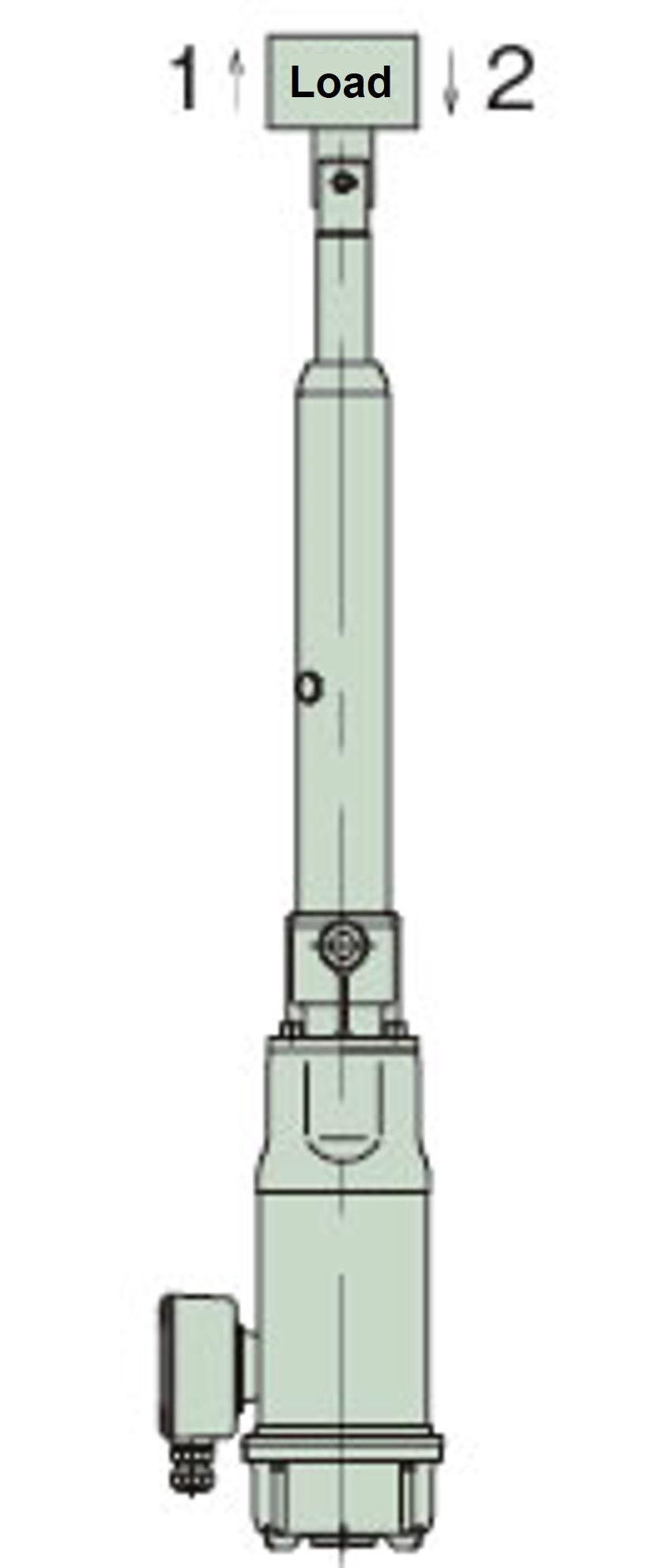

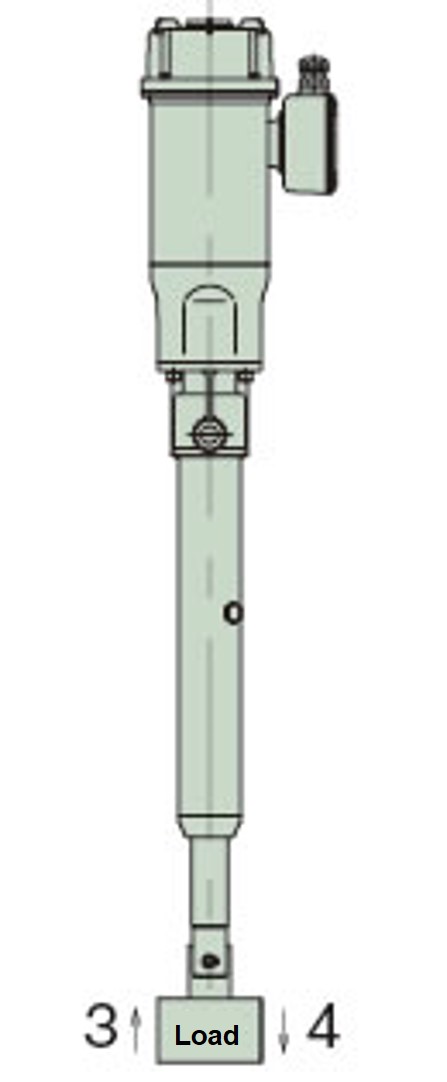

| Push-up load (1, 3) | Hanging load (2, 4) | ||||||||

| 50Hz | 60Hz | 50Hz | 60Hz | ||||||

| coasting distance | Stopping Accuracy | coasting distance | Stopping Accuracy | coasting distance | Stopping Accuracy | coasting distance | Stopping Accuracy | ||

| LPGA070 LPGB070 LPGC070 |

L | 6.9 | ±0.4 | 10.0 | ±0.5 | 10.6 | ±0.4 | 14.9 | ±0.5 |

| M | 15.0 | ±1.1 | 21.5 | ±1.3 | 21.8 | ±1.2 | 30.1 | ±1.4 | |

| H | 15.4 | ±1.4 | 21.7 | ±1.7 | 23.7 | ±1.5 | 32.7 | ±1.8 | |

| U | 34.2 | ±2.8 | 47.9 | ±3.4 | 60.6 | ±3.1 | 81.2 | ±3.8 | |

| LPGA100 LPGB100 LPGC100 |

L | 6.1 | ±0.4 | 9.0 | ±0.5 | 10.6 | ±0.4 | 14.9 | ±0.5 |

| M | 13.8 | ±1.1 | 19.8 | ±1.3 | 22.1 | ±1.2 | 30.5 | ±1.4 | |

| H | 14.1 | ±1.4 | 19.8 | ±1.7 | 23.8 | ±1.5 | 32.7 | ±1.8 | |

| U | 32.0 | ±2.8 | 45.0 | ±3.4 | 66.9 | ±3.1 | 88.2 | ±3.8 | |

| LPGA150 LPGB150 LPGC150 |

L | 4.6 | ±0.4 | 6.6 | ±0.5 | 7.1 | ±0.4 | 9.8 | ±0.5 |

| M | 10.6 | ±1.1 | 14.7 | ±1.3 | 15.6 | ±1.2 | 21.3 | ±1.4 | |

| H | 13.7 | ±1.4 | 19.0 | ±1.7 | 21.8 | ±1.6 | 30.0 | ±1.9 | |

| LPGA300 LPGB300 LPGC300 |

L | 3.3 | ±0.4 | 4.6 | ±0.5 | 5.1 | ±0.4 | 6.9 | ±0.5 |

| M | 8.6 | ±0.8 | 12.4 | ±0.9 | 23.2 | ±0.8 | 29.4 | ±1.0 | |

| H | 9.4 | ±1.0 | 13.1 | ±1.2 | 19.0 | ±1.1 | 25.0 | ±1.3 | |

*The values in the above table may differ slightly depending on the model.

Note: In actual operation, it is necessary to prevent the rod from rotating.

Coasting distance: This indicates the distance until the limit switch or stop button is activated and the machine stops. This coasting distance varies depending on the load and the operating circuit.

Stopping accuracy: Indicates the amount of variation in stopping position when stopping is repeated. The table above assumes a time lag of ±25% for the relay and brake.

Estimated life span

Expected travel distance for Trapezoidal Screw specifications

Cylinder (nut) travel distance: 25km

*If the device is operated frequently, it may reach the end of its lifespan earlier than expected, so please check that the expected lifespan is being met.

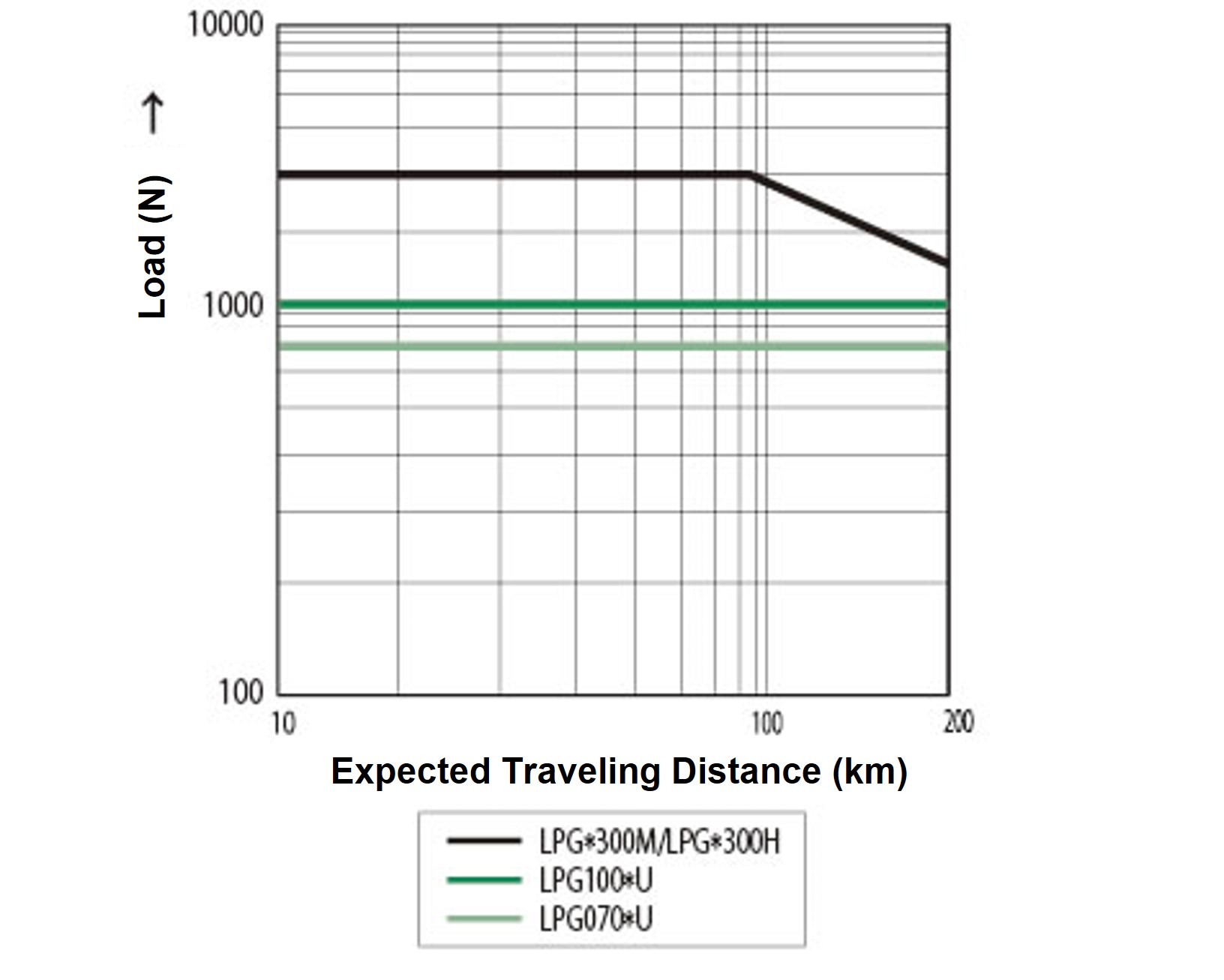

Expected travel distance for Ball screw specifications

The lifespan of Ball screw is determined by flaking caused by fatigue on the rolling surface. Please check this expected travel distance graph for an approximate lifespan. However, if there is a lot of impact or if proper lubrication and maintenance are not performed, the expected travel distance will be significantly shorter.

Expected travel distance (km) = Actual load stroke (m) × frequency of use (times/day) × number of operating days/year × 10-3 × expected number of years

The graph on the right is based on the L10 lifespan. L10 lifespan is the lifespan that 90% or more of the total can achieve, expressed in terms of travel distance. When selecting Power Cylinder based on lifespan, please select the model number from this graph.

If the load fluctuates significantly midway through the stroke, calculate the equivalent load (P M) using the formula below.

PM = PMIN + 2×PMAX 3

P M: Equivalent load N{kgf}

P MIN: Minimum load N{kgf}

P MAX: Maximum load N{kgf}

Expected travel distance

Selection considerations: G series

Brake holding power

The load holding force of Power Cylinder G Series when stopped is greater than the rated thrust, so it can be used to hold the rated load. This holding force is generated by the braking action of the brake-equipped motor. The brake is a spring-operated type that always applies braking force with spring force when stopped, and the brake torque has a holding force of more than 150% of the motor's rated torque.

*When selecting Power Cylinder, please select Power Cylinder with sufficient thrust, taking into account a safety factor, so that the working load (static and dynamic) does not exceed the rated thrust.

Brake stop

This method activates and stops the brake by operating a limit switch or a stop button, allowing for multi-stage positioning such as upper and lower stroke limits and intermediate stops. The coasting amount and stopping accuracy vary depending on the operating speed and load.

When precise positioning is required or when the operating speed is high, we recommend Brake external connection. When setting the limit switch, give a stop signal taking into account the coasting distance.

Reference values are shown in Table 3 above.

C-type press stop allowable number of times

When pushing (pulling) and stopping frequently

If you plan to use it more than 10 times a day, please contact us.

- Note)

1. If you are using the product for a push (pull) stop, we recommend that you use a separate wiring for the brake section. - 2. When using with a push (pull) stop, the strength of the mating device must be 250% or more of the rated thrust.

- 3. When pressing (pulling) to a stop at H or U speed, use an inverter to decelerate to a stop. Please contact us for details.

Allowable weight when driving horizontally

The safety device does not work at start-up when opening and closing the damper or hopper gate, or when performing normal reversing, tilting, or lifting, but if the inertia is large, such as when the cart moves horizontally, the safety device will work at start-up and operation may not be smooth. Please refer to Table 4 for the allowable mass m for each model.

- Cart mass: m kg

- Friction coefficient: μ

- Bogie running resistance: = μ m ≦ Rated thrust

Table 4 Allowable mass m

| Power Cylinder model number | LPGA070 LPGB070 LPGC070 |

LPGA100 LPGB100 LPGC100 |

LPGA150 LPGB150 LPGC150 |

LPGA300 LPGB300 LPGC300 |

|

|---|---|---|---|---|---|

| speed | L | 1150 | 2085 | 1220 | 2060 |

| M | 170 | 280 | 310 | 1560 | |

| H | 130 | 240 | 270 | 790 | |

| U | 71 | 102 | - | - | |

Linked operation method

Power Cylinder can be used for transporting and lifting work by sharing the load among several Power Cylinder as shown in Figure 1. This is because there is little change in speed due to load fluctuations.

Please pay attention to the items on the right when selecting.

Figure 1: Interlocking operation of several Power Cylinder

Control Method

To start, turn on the power for all units at the same time, and to stop them, use the limit switch on each Power Cylinder. Avoid controlling all units with one limit switch, as this will cause cumulative stroke errors.

Linkage Accuracy

The speed fluctuation of each Power Cylinder during operation is caused by load fluctuations and is generally about 5%. For variations when stopping, refer to the stopping accuracy in Table 3 above. If you wish to synchronize, please use the multi-specification.

Required thrust per unit N{kgf} Number of Power Cylinder used x Multiple factor

Table 5. Multiple factor

| Number of Power Cylinder used | 2 units | 3 units | 4 units | 5 units | 6 units |

|---|---|---|---|---|---|

| Multiple factor | 0.8 | 0.7 | 0.6 | 0.55 | 0.5 |

If the cylinder stroke is short, a high-speed cylinder cannot be used because the operating time per stroke is short, making it difficult to control.The minimum required stroke when the motor is energized for 0.5 seconds is shown below, so please use this as a reference when determining the speed.

| Speed symbol | H | U |

|---|---|---|

| Nominal speed mm/s 50/60Hz | 100/120 | 200/240 |

| 0.5s travel distance during operation mm | 50/60 | 100/120 |

| Estimated maximum coasting distance mm (reference) | 24/33 | 67/89 |

| Minimum required stroke mm | 74/93 or higher | 167/209 or more |

*The values in the table represent values at 50Hz/60Hz.