technical data linear actuator Linipower Jack Handling

Terms and explanations

1. Basic capacity:

The maximum load that a jack can hold or lift. However, depending on the nature of the load, it is necessary to select and use it with a load that includes Service factor (Sf).

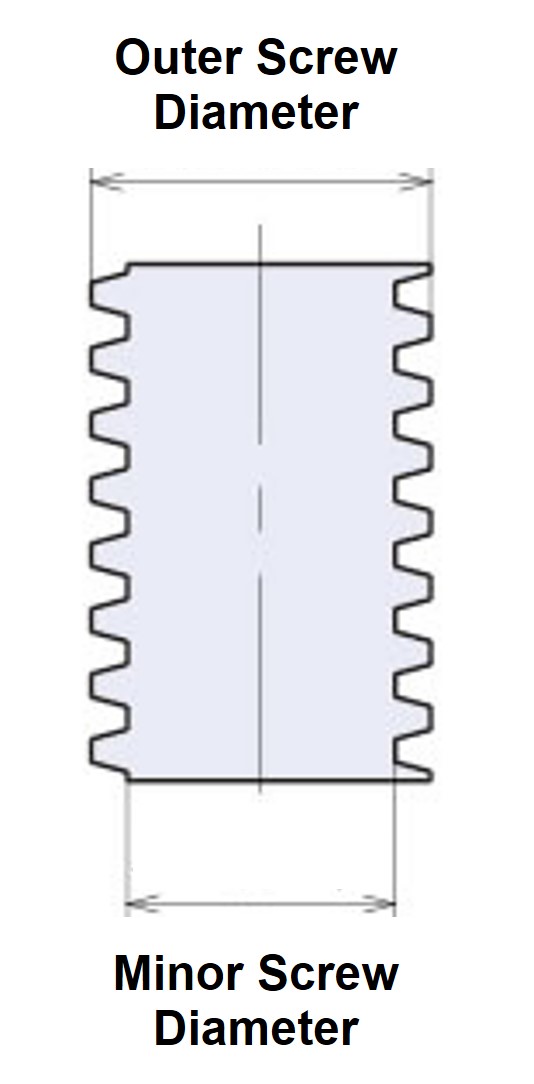

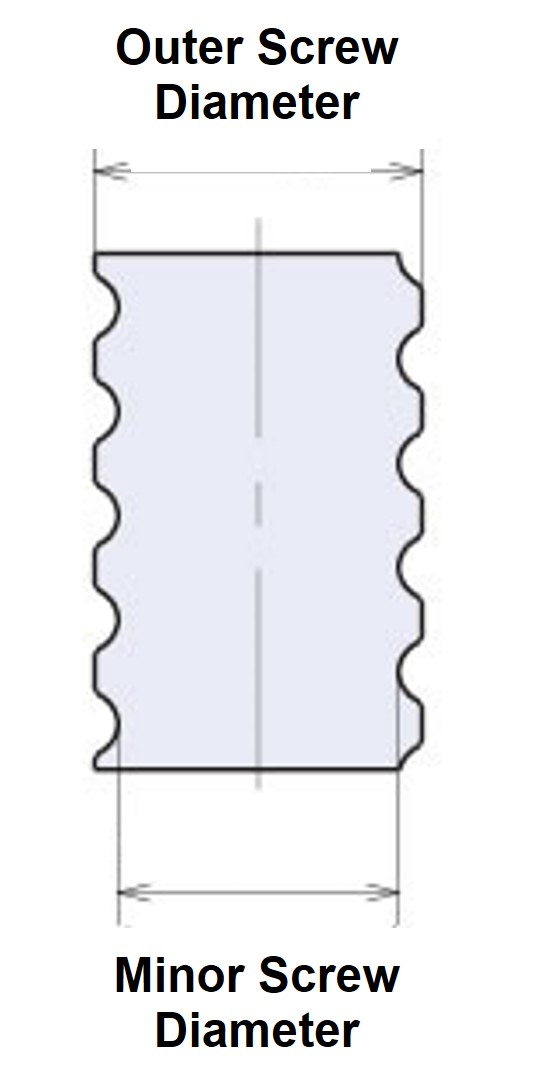

2. Screw outer diameter/thread root diameter:

See the figure below.

[Trapezoidal Screw]

[Ball screw]

3. Screw lead:

In a jack, this is the amount of axial movement of the screw shaft (or the nut in the case of a traveling nut specification) per rotation of the worm wheel.

4. Stroke:

The distance that the screw shaft (or nut in the case of a traveling nut specification) can move.

XMAX-XMIN in the dimension drawing.

5. Worm speed ratio:

The number of rotations of the input shaft required to rotate the worm wheel once.

(reduction ratio between input shaft and worm wheel)

6. Overall efficiency:

The overall operating efficiency of the jack, including screw efficiency and worm efficiency.

7. Maximum allowable input capacitance:

The allowable input capacity that defines the relationship between load and screw shaft speed (input rotation speed).

Use within the range that does not exceed Percentage duty cycle (%ED) or the surface temperature of the jack reducer (MAX. 80°C).

8. No-load idling torque:

The input torque required to rotate the input shaft under no load.

9. Holding torque:

The input torque required for the input shaft to hold the same load as the basic capacity.

10. Allowable input shaft torque:

This refers to the allowable torque of the input shaft only and is limited by the shaft strength.

When jacks are connected in series, the sum of the torque required for one jack and the torque transmitted to other jacks is limited to an allowable value or less.

11. Required input torque for basic capacity:

The input torque required for the input shaft when lifting or lowering the same load as the basic capacity.

12. Screw travel per input shaft rotation:

The amount of movement of the screw shaft (or nut in the case of traveling nut specifications) per rotation of the input shaft.

13. Maximum input rotation speed at basic capacity:

The maximum rotational speed that can be input to the input shaft when lifting a load equal to the basic capacity.

14. Screw shaft rotation torque at basic capacity:

The rotational torque that causes the screw shaft (or nut in the case of traveling nut specifications) to rotate when lifting or lowering a load equal to the basic capacity.

Unless anti-rotation measures are taken on either the device side or the jack side, the screw and nut will rotate together and will not move up or down.

15. allowable load:

The load can be calculated based on the maximum allowable input capacity once the jack's screw shaft speed (input rotation speed) is determined.

16. Buckling:

The screw shaft of a jack is long compared to its cross section, so when the compressive force in the axial direction of the screw exceeds a certain value, the screw shaft loses stability and undergoes a sudden, large bending deformation, which is called buckling.

The buckling load varies depending on the support method (installation condition).

17. Allowable screw shaft rotation speed:

The screw shaft rotates under its own weight deflection, and when the rotation speed approaches the natural frequency of the screw shaft, resonance occurs and vibration occurs. Therefore, it must be used at a rotation speed lower than the resonance point (critical rotation speed).

The resonance point is called the allowable screw shaft rotation speed. For jacks, consideration must be given to the traveling nut specifications, which rotate the screw shaft.

18. Coasting distance:

The distance until the limit switch or stop button is activated and the machine stops.

This coasting distance varies depending on the load conditions, brake characteristics, and operating circuit.

19. Stopping accuracy:

The amount of variation in the stopping position when starting and stopping is repeated.

20. Self-locking:

This means that the jack alone, without a brake device, can hold a load.

All JWM (Trapezoidal Screw type) frame numbers 002 to 1000 are self-locking in calculations.

21.Load Percentage duty cycle:

Percentage duty cycle (also called %ED) is the percentage of operating time in one cycle.

Percentage duty cycle (%ED) = Operation time per cycle Operation time per cycle + Down time x 100 (%)

22. Generated thrust:

Thrust (maximum lifting load) calculated from the motor rated torque for a motor or Gear Motor motor jack alone.

However, selection is required when operating a jack with a drive unit in conjunction with other jacks.

23. Ball screw life:

The lifespan of Ball screw is determined by flaking caused by fatigue on the ball rolling surface, and is expressed as the total travel distance by the screw shaft (nut) until flaking occurs.

This peeling phenomenon due to fatigue will vary to a certain extent even when many identical components are operated under the same conditions.

The lifespan that can be reached without causing peeling in 90% or more of the total is called the rated lifespan (B10 lifespan).