technical data High-speed lifter Lift Master Selection

Points to note when considering

1. Acceleration and deceleration times

- - Because Lift Master has a fast lifting speed, if it is equipped with a three-phase motor, inverter control is required and sufficient acceleration and deceleration time must be provided.

Also, if a servo motor is used, please allow sufficient acceleration and deceleration time.

Sudden acceleration or stopping may result in a decrease in stopping accuracy or vibration of the workpiece.

If Lift Master vibrates when starting and stopping due to the installation surface, arm rigidity, or load conditions, please use it with a longer acceleration/deceleration time.

Also, if you want to reduce the amount of vibration, consider fixing the top of Lift Master. - ・ The "speed" shown in the standard model list (Ball screw type, Trapezoidal Screw type) is the maximum speed.

When calculating the lift time, please include the acceleration and deceleration time in the calculation. - ・If you require further reduction in lifting time, high frequency operation, multi-point positioning, linked operation, etc., we recommend the servo motor version.

2. Inverter control

- ・A large regenerative current is generated when the voltage drops, so please provide an inverter regenerative resistor with sufficient capacity based on your operating conditions. Please consult with the inverter manufacturer regarding the capacity of the regenerative resistor.

- ・ We recommend using an inverter with a capacity one frame larger than the motor.

- - Create a sequence that activates the brake when the inverter trips.

3. Fall prevention

- ・ Lift Master uses a motor with a non-excitation actuated brake. If you are using your own motor as a servo motor, please use the brake-equipped keyway shaft specification.

In addition, please prepare your own fall prevention mechanism in case of a fall. We can also manufacture special-order fall prevention pins.

4. Servo motor control

- -Please use the servo motor at or below the rated rotation speed.

- ・A large regenerative current occurs when descending. Install a sufficient regenerative resistor according to the conditions.

- ・Even in an emergency, do not use the motor's built-in mechanical brake for braking. Be sure to use control logic that activates the mechanical brake after deceleration by the dynamic brake. For details, refer to the motor manufacturer's Instruction Manuals.

About the selection

Conditions of use required for selection

- 1. Equipment used and required number

- 2. Amount of material moving up and down

- 3. Speed

- 4. Stroke

- 5. Load overhang

- 6. Frequency of use

- 7. Usage environment

Selection Procedure

- 1. Check that the machine, method of use, and environment are suitable for Lift Master.

- 2. Select a model number with a rated load that satisfies the required lifting load from the list of standard models (Ball screw type or Trapezoidal Screw type).

*If the lifting load exceeds the rated load, please consider operating multiple units in conjunction.

Please contact us regarding the selection and control method for multiple linked operation. High load specifications are also available as special orders, so please contact us. - 3. Check that the lifting speed satisfies the nominal speed of the selected model.

*We can also accommodate specifications with increased lifting speed, so please contact us for details. - 4. Check the stroke required.

*If the stroke exceeds 1.5m, we can handle it as a special order, so please contact us. - 5. Check below to see if the allowable overhang load for the selected model is met.

Check the allowable overhang load (OHL)

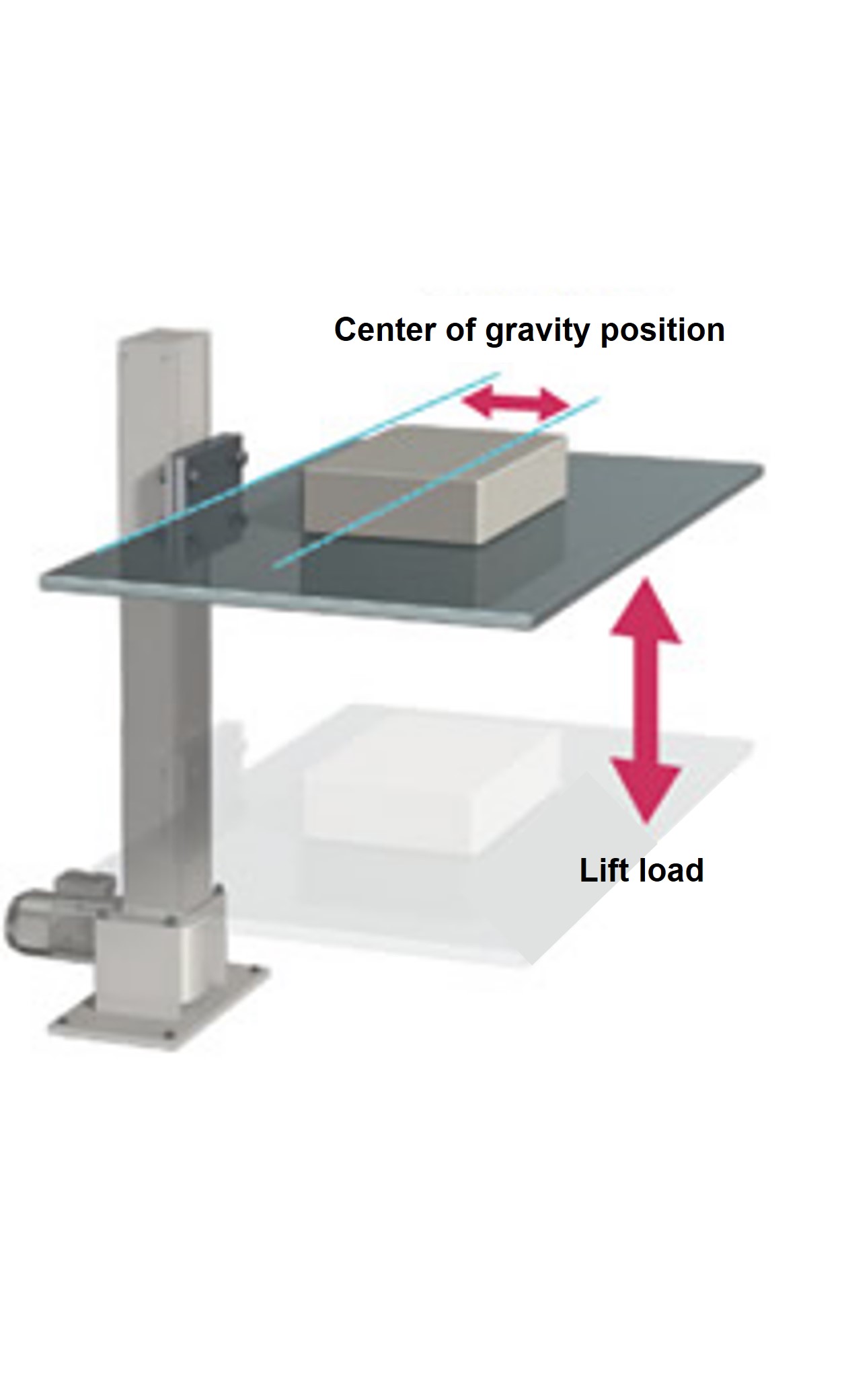

By checking the lifting load and center of gravity, you can easily select Lift Master. As shown in the diagram on the right, the intersection of the lifting load and center of gravity is the allowable overhang load value.

Please see the overhang load curve for each model (Ball screw type / Trapezoidal Screw type).

Note

- - When a load is applied to the arm, Lift Master will distort in the direction of the load, and it is necessary to anticipate that the tip of the arm will drop below horizontal. The amount of distortion not only increases the longer Lift Master 's stroke, but also affects the rigidity of the arm and installation surface.

- - If you want to reduce the amount of distortion and vibration when starting and stopping, consider fixing the top of Lift Master.

- ・Please contact us separately for details regarding the amount of distortion of Lift Master.

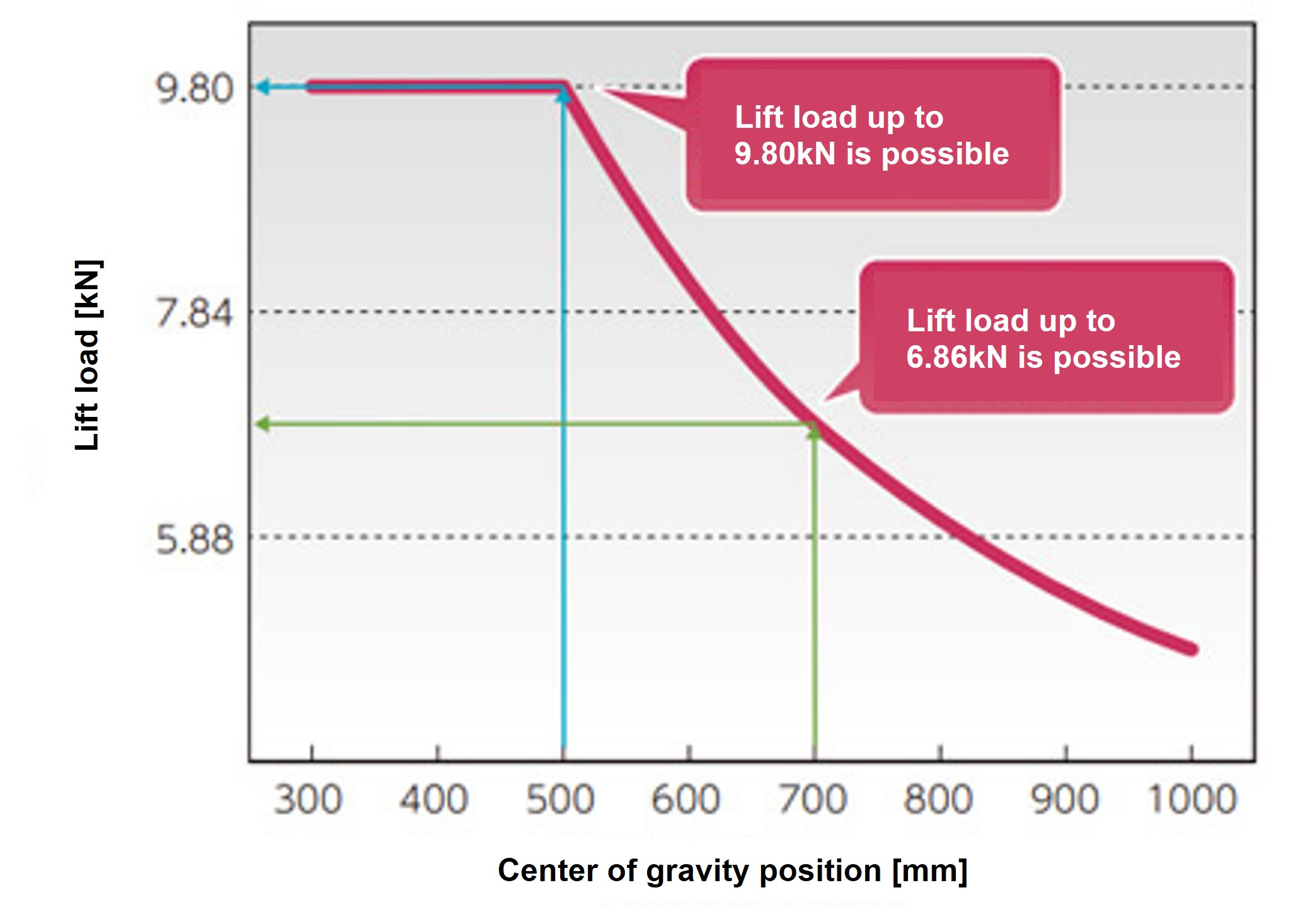

LMEB1000

(Workpiece mounting surface reference: see outline drawing)

For LMEB1000

Example 1: When the center of gravity is 500 mm, a load of up to 9.80 kN can be lifted.

Example 2: When the center of gravity is 700 mm, a load of up to 6.86 kN can be lifted.