Technical data Coupling Handling

Power Rigid Coupling EPR Series

Installation

Wipe the shaft surface and the inner circumference of the body clean, and apply a thin layer of oil to each part.

1. Mounting shaft diameter tolerance

The tolerance of the shaft diameter when installing the Power Rigid Coupling should be as shown in the table below.

| Mounting shaft diameter | Φ35 | Other than Φ35 |

|---|---|---|

| Recommended Tolerance | +0.010 -0.010 |

h6 or h7 |

Φ35 is the shaft diameter of the servo motor, and the tolerance is (+0.01 to 0).

Therefore, the hole tolerance of the coupling is also adjusted accordingly.

Please note that even if Ball screw screw shaft diameter is Φ35, the hole diameter tolerance for both is the same.

- - The yield point of the mounting shaft material must be 343MPa {35kgf/mm 2} or higher (S45C equivalent or higher).

- - The surface roughness of the shaft must be Ra1.6 or less.

2. Centering

- (1) Attach the coupling to one side of the shaft and tighten the outer ring according to the procedure.

- (2) Leave the outer ring of the other shaft untightened. This shaft can rotate freely within the shaft hole of the coupling.

- (3) Fix the dial gauge to the base (coupling case, etc.) and check the runout of each shaft.

- 1. Place a dial gauge on the outer periphery of the center flange of the coupling body when the shaft is fastened to the coupling.

Rotate this shaft and read the runout, keeping it within 3/100 (Figure 1). - 2. Next, place a dial gauge on the other shaft, rotate this shaft, and read the runout to bring it within 3/100.

- 1. Place a dial gauge on the outer periphery of the center flange of the coupling body when the shaft is fastened to the coupling.

- (4) Check that the runout on both dial gauges is within the specified value, then tighten the other outer ring according to the correct procedure.

- (5) Finally, check the flange runout on the main body with a dial gauge to make sure it is within 3/100.

| Dial gauge on the outer periphery of the main body |

|---|

| Within 3/100 mm |

Figure 1

Figure 2

3. Tightening the pressure bolt

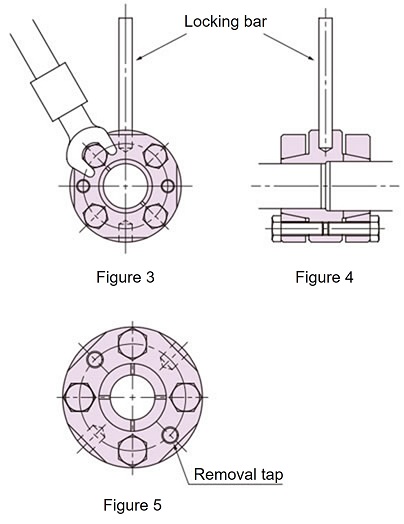

When tightening the pressure bolts, first pretighten them by hand, then gradually tighten the diagonal bolts (Fig. 3).

Finally, use a torque wrench to tighten to the specified torque of 16.7 N·m {1.70 kgf·m}.

At this time, place a dial gauge on the outer diameter of the body and tighten the pressure bolt so that the gauge runout is as close to 0 as possible (Fig. 2).

Additionally, if you insert a locking bar into the drilled holes on the outside of the body to secure it in place, the work will be easier (Figure 4).

4. Removal

加圧ボルトをゆるめるとテーパロックの締付けが解除されます。もし固着状態の場合には、アウタリングの取外し用タップ(2カ所)に加圧ボルトを締めて、外すことができます。(図5)5. Inspection

取付後試運転を行い、振動、異音等の異常がないことを確認してください。また、加圧ボルトのゆるみ等がないかも確認してください。6. Maintenance

年に1~2回、取付状態の確認をしてください。もし異常が見つかれば速やかに対処してください。