technical data Miter Bevel Gearbox Selection

Miter Gear Box selection example

Selection example 1

General selection

Usage layout

Operating conditions

- · A general-purpose motor (15kW x 4P x 60Hz) is directly connected to the motor via a coupling and input from the lateral shaft.

- - A PCD 100mm sprocket is installed on the cross shaft side.

- - Load transmission kW is operated at 10kW.

- - Operating time is 10 hours/day with some impact load. Intermittent operation with 12 starts and stops per hour.

- ・The speed ratio is 1:1.

Usage atmosphere

- Indoors, always 30°C, normal atmosphere (no dust, etc.)

option

- ・None in particular (standard products will be used)

(1) Determination of Service factor

Under the operating conditions (load with some impact, 10 hours/day, start/stop 12 times/hour), Service factor is 1.50 according to Table 1.

(2) Determination of design kW

design kW = 10kW (load transmission kW) x 1.50 (Service factor) = 15kW Therefore, design kW is 15kW.

(3) Deciding on size

The size that satisfies design kW = 15kW and input rotation speed of 1750 r/min is selected from kW ratings table as ED6M.

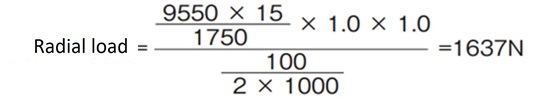

(4) Check the radial load

(Radial load is applied to the center of the cross shaft)

From Table 2, for chain transmission, the OHL coefficient f = 1.0, and since the radial load is applied to the center of the shaft, the acting position coefficient Lf = 1.

From the radial load confirmation formula and usage conditions,

The allowable radial load on the ED6M cross shaft is 2303N > 1637N, so it can be used within the allowable value.

(5) Deciding on the model number

The model number is determined based on the shaft arrangement, rotation relationship, and mounting style of the layout in use.

ED6M-1-RY can be selected. *Please check the direction of rotation.

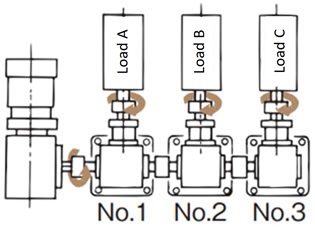

Selection example 2

Line shaft drive

Usage layout

Operating conditions

- Loads A, B, and C are all uniformly loaded at 245 N·m and used for 8 hours per day.

- - The input rotation speed is 300 r/min and all reduction ratios are 1:1.

Usage atmosphere

- Indoors, always 30°C, normal atmosphere (no dust, etc.)

option

- ・None in particular (standard products can be used)

*Notes when selecting a line shaft drive

In the case of a line shaft drive, the load on the gears and the load on the line shaft (cross shaft) are different, so they must be selected separately.

Please refer to the allowable torsional transmission capacity of the cross shaft only (allowable torque of the cross shaft).

(1) Determination of Service factor

From Table 1, under the operating conditions (uniform load, 8 hours/day), Service factor = 1.0.

(2) Selection of each Miter Gear Box

1. Miter Gear Box No. 1

- The gear operates only load A. → A transmission capacity of 245N・m × 1.0 = 245N・m or more is required.

- The cross shaft drives loads A, B, and C. → A cross shaft torque of at least (245N・m + 245N・m + 245N・m) × 1.0 = 735N・m is required.

Therefore, ED10M is selected based on kW ratings table (see product page) and the cross shaft allowable torque.

[ED10M transmission capacity 513N・m > 245N・m, cross shaft allowable torque 891N・m > 735N・m]

2. Miter Gear Box No. 2

- ・The gear operates only with load B. → A transmission capacity of 245N・m x 1.0 = 245N・m or more is required.

- The cross shaft drives loads B and C. → A cross shaft torque of at least (245N・m + 245N・m) × 1.0 = 490N・m is required.

Therefore, ED8M is selected based on kW ratings table (see product page) and the cross shaft allowable torque.

[ED8M transmission capacity 331N・m > 245N・m, cross shaft allowable torque 627N・m > 490N・m]

3. Miter Gear Box No. 3

- - Both the gear and the cross shaft operate with only load C. → A transmission capacity and cross shaft torque of 245N・m x 1.0 = 245N・m or more is required.

Therefore, ED8M is selected based on kW ratings table (see product page) and the cross shaft allowable torque.

[ED8M transmission capacity 331N・m > 245N・m, cross shaft allowable torque 627N・m > 245N・m]

(3) Deciding on the format

The model number is determined based on the shaft arrangement, rotation relationship, and mounting style of the layout in use.

No.1 ED10M-1-LR-OY

No.2 ED8M-1-LR-OY

No.3 ED8M-1-ROY can be selected.

*Please check the direction of rotation.