technical data Clutch Handling

MI Series Handle with care

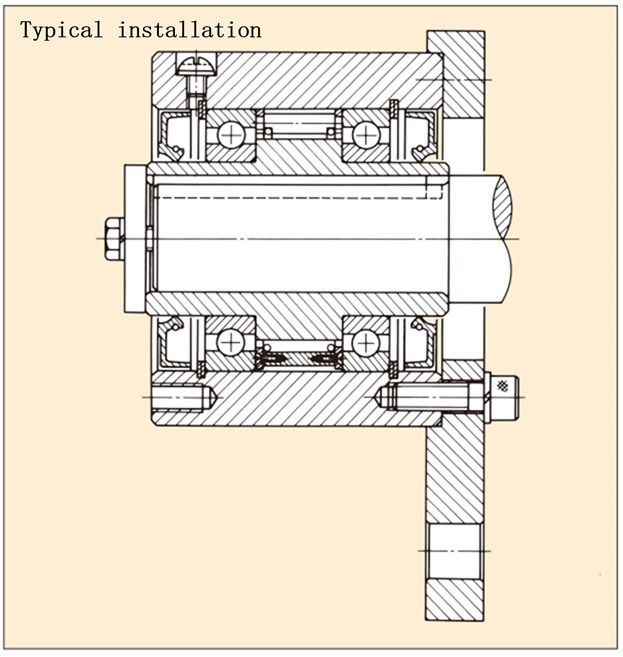

- 1. When attaching a swing arm or other part to outer race, make sure that it is in contact with outer race 's outer circumference B dimension (here) and securely attach it to the tapped hole at the end of outer race using a bolt with a strength classification of 10.9 or higher. We recommend a tolerance of H6 or H7 for the inlet part.

- 2. A shaft diameter tolerance of h6 or h7 is recommended.

- 3. Always use a parallel key (MI750 and above are delivered with a key), and never use the top of the key.

- 4. Use two types of parallel keys conforming to JIS B1301-1959 (old JIS). (For MI750 and above, keys with special height dimensions are included. The key groove depth for the shaft must conform to JIS.) However, the relationship between shaft diameter and key dimensions may not conform to JIS.

- 5. When fitting onto the shaft, apply force to the end face inner race. Never hit outer race.

- 6. When using for indexing, please note the following points to improve feeding accuracy.

- (1) Use an end plate on the shaft end, tighten inner race end face sufficiently, and ensure that the key and keyway are fully aligned.

- (2) Use both a brake and a reverse prevention cam clutch. If the required accuracy is relatively rough, using either one alone may be sufficient.

- 7. If using at or near the maximum allowable torque, we recommend using a key and shaft that has been thermally refined or hardened. (Keys included with MI750 and above are hardened keys.) Also, be sure to check the strength of the shaft.

- 8. If a thrust load is applied to the Cam Clutch, provide a separate device to bear the thrust load.

- 9. Lubricant is not included at the time of shipment, so please apply the recommended lubricant before use.

- 10. For information on lubrication and maintenance, please see here.