technical data Clutch Handling

MA Series Handle with care

- 1. We recommend a shaft diameter of h6 or h7.

- 2. Always use a parallel key and never use the top of the key. Use a JIS B1301-1996 (New JIS) parallel key (normal type).

- 3. When fitting onto the shaft, apply force to the end face of inner race. Never hit outer race.

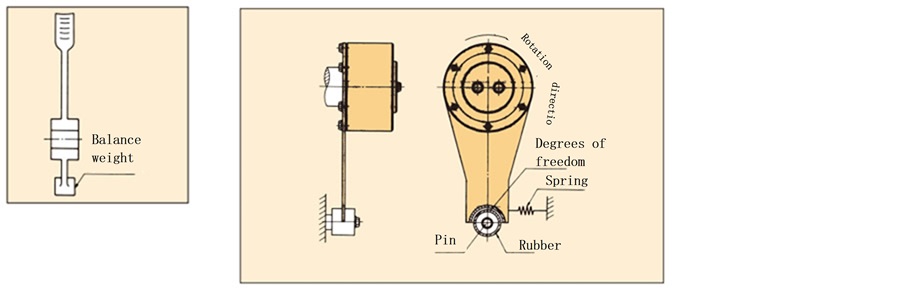

- 4. When using with a pitching machine, attach a balance weight to the arm shaft to balance it with the arm. If it is unbalanced, a large vibration load may be generated.

- 5. Use a cushioning material such as rubber at the fixed part of the torque arm to absorb vibration loads.

- 6. Please refer to the installation diagram and usage instructions below.

- 7. For information on lubrication and maintenance, please see here.

Backstop with repeated impact loads

This is used to prevent reverse rotation when instantaneous and shock vibration loads are repeatedly applied, such as the reaction force of a spring. Typical examples include those used in tennis machines and pitching machines.

The sprocket (with bearings) that is constantly rotating due to the reduction motor has claws on its side that come into contact with the claws on hub end face of the arm (keyed to the shaft) and push up the arm.

The spring, one end of which is attached to eccentric disk (keyed to the shaft), is stretched as the arm shaft rotates, and then suddenly contracts once it passes the top dead center. At this point, the arm throws out the ball.

After the throw, the arm continues to rotate past the bottom dead center due to its own inertia, extending the spring and reaching a certain angle (θ). During this time, the cam clutch continues to rotate freely.

Once the arm has rotated to θ degrees, it will try to reverse suddenly due to the contraction force of the spring, but the cam clutch will engage and prevent this reversal.

The reversing torque generated at this time is an impulsive vibration torque, which is the load characteristic of the backstop when subjected to repeated loads.

Points to note

Attach a balance weight to the arm shaft to maintain dynamic balance. If it is left unbalanced, excessive vibration will occur when the cam clutch engages. Please note the following to minimize the impact when reverse torque is applied.

- (1) Insert a cushioning material such as rubber where the tip of the torque arm is fixed to the frame to absorb vibration loads.

- (2) Do not completely fasten the tip of the torque arm with a bolt, etc., but leave some freedom of movement. If it is completely fastened, it may cause twisting inside the cam clutch and result in damage.

- (3) To always keep the clearance between the surface at the tip of the torque arm that receives the reverse torque and the buffer material to a minimum, apply a moment in the reverse direction to the torque arm using a weak spring or similar.