technical data Drive chain Chain Selection

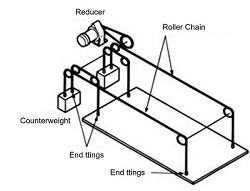

7. Example of hanging drive

There are many examples of roller chains being used for lifting.

By taking advantage of the characteristics of roller chains and following the correct selection and precautions, roller chains can be used for lifting.

The following diagrams show typical hanging applications. (Safety devices should be considered separately.)

For balance

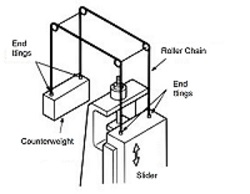

Lifting equipment(1)

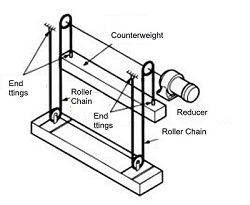

Lifting equipment (2)

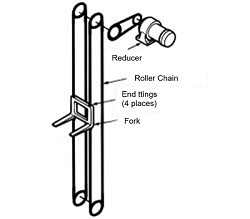

Lifting equipment(3)

Points to note when selecting a roller chain for lifting

1. When there are restrictions

When selecting a roller chain, if there are restrictions imposed by law or guidelines, select according to those restrictions as well as allowable tension, and then select the roller chain with the larger allowance.

2. Links

Please use F-type connecting links. Offset links cannot be used.

3. Lubricating

When oiling, remove as much load as possible from articulate parts of the roller chain. Also oil the joints with End fixture (end bolts and connecting links, etc.).

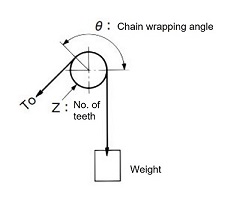

Counterweight mass that will not cause tooth skipping when using roller chains for hanging

Tk = To × {sinΦ / sin(Φ + 2α)} K-1

- Tk: Minimum weight tension (minimum back tension)

- To: Roller chain tension

- Φ: Minimum sprocket pressure angle Φ = 17°- 64° Z

- 2α: Sprocket index angle 2α = 360° Z

- K: Number of meshing teeth K = θ 360 × Z ...round down to the nearest whole number for safety reasons

Example: If To = 10.8kN {1100kgf}, Z = 13T, θ = 120°

- Φ = 17° - 64° Z = 17° - 64° 13 = 12.077

- 2α = 360° Z = 360° 13 = 27.692

- K = θ 360° × Z = 120° 360° × 13 = 4.33 ... K = 4

- Tk = 1100 × {sin12.077 / sin(12.077 + 27.692)} 4-1 = 38.5(kg)

Therefore, if the weight mass is 39 kg, the teeth will not skip.

However, this will vary depending on factors such as layout, wear on the roller chain and sprocket teeth, etc. The above figures should be considered as a guideline.