technical data Drive chain is Drive chain?

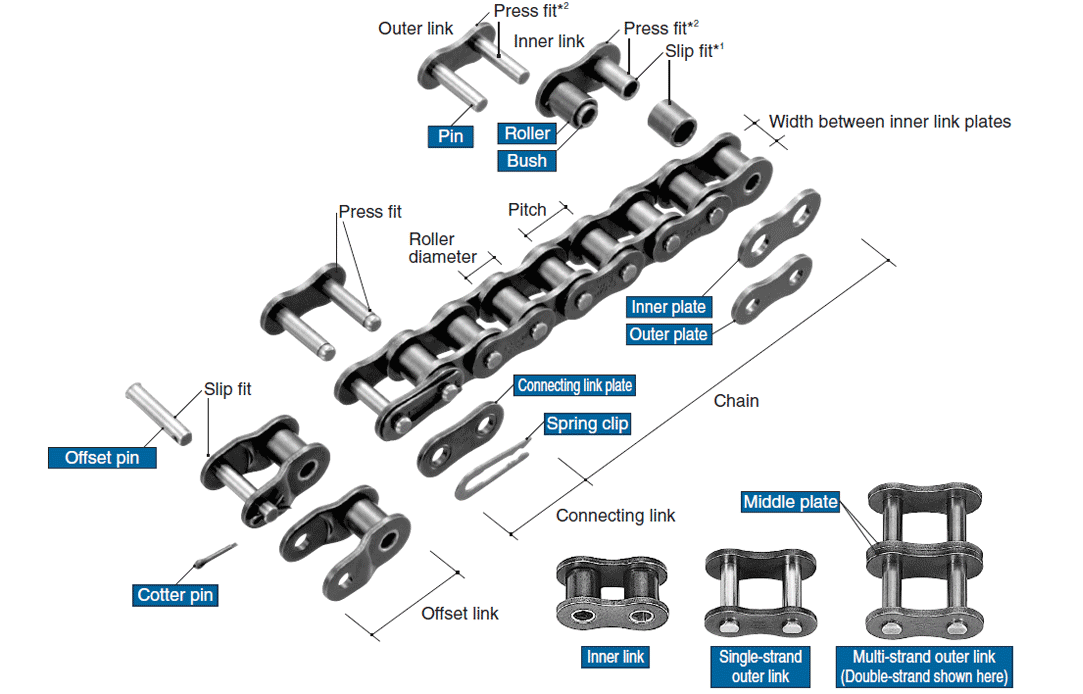

Roller chain structure

Basic structure

Plates are members that bear the tension applied to the roller chain during power transmission. This tension is usually a repeated load, but can sometimes be accompanied by impact. Therefore, plates are required to have not only static tensile strength, but also high fatigue strength, impact strength, and dynamic toughness.

The pins are subjected to shear and bending forces through the plate, and at the same time, when the roller chain bends and meshes with the sprocket, they form the bearing together with the bushing. Therefore, they need to have shear strength, bending strength, toughness, and wear resistance.

The bushing receives complex forces through various parts, but in particular, when it engages with the sprocket, it receives repeated impact loads through the rollers, so it must have high impact fatigue strength.In addition, it must be wear-resistant because it acts as a bearing when mated with the pin.

When a roller chain engages with a sprocket, the roller is subjected to repeated impact loads as it collides with the front teeth. After engaging, the equilibrium position of the engagement with the teeth changes depending on the amount of tension, so the roller moves along the tooth surface while being sandwiched between the tooth and bushing, and is subjected to compressive loads and frictional forces. Therefore, impact fatigue strength, compressive strength, and wear resistance are required.

Note: RS15, RS25, RS35 and RS11-SS do not come with rollers.

Two bushings are press fit fitted into two inner plates, and rollers are fitted to the outside of the bushings so that they can rotate. The same design is used for both single- and multiple-strand chains.

outer link has two pins press fit into two outer plates. In the case of multiple strand roller chain, an intermediate plate is added to outer link. The intermediate plate of RS roller chain is slip fit (*1), while that of Super chain is press fit (*2).

| The three basic dimensions | *1 slip fit | *2 press fit | ||

|---|---|---|---|---|

| Pitch, roller diameter, and Inner link width are the three basic dimensions of a roller chain. When these dimensions are the same, the roller chain and sprocket are dimensionally compatible. |

A fit in which there is always a gap when the shaft and hole are combined. A fit in which the hole tolerance range is completely above the shaft (pin or bushing) tolerance range. | A fit that always creates interference when the shaft and hole are combined. A fit in which the tolerance range of the hole is completely below the tolerance range of the shaft (pin or bushing). |

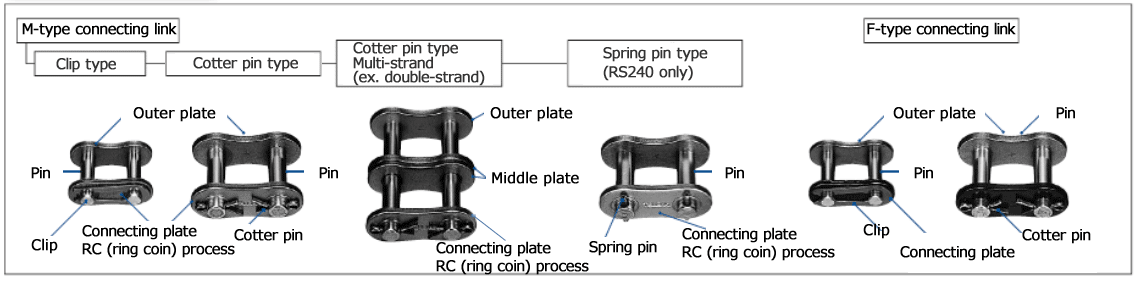

Connecting parts

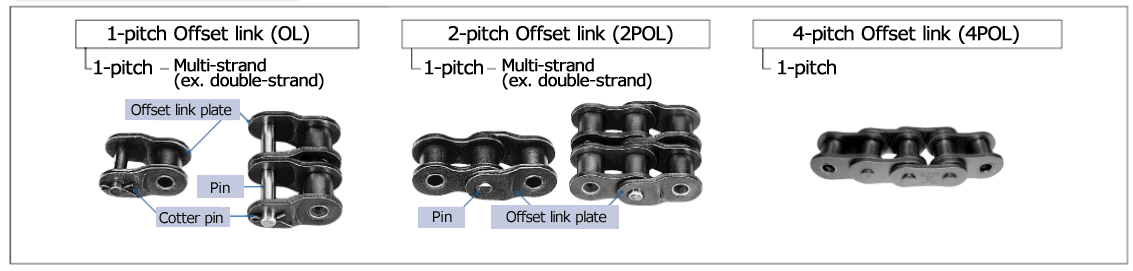

Roller chains are usually made up of many connected links and are used either as endless chains or with the ends fixed, but in either case a connecting link is required (and special connecting links are used for hanging applications, etc.). Also, if a roller chain has an odd number of links, offset links can be used, but it is best to design it with an even number of links whenever possible.

| Chain Type | Connecting link name | Pin connecting link plate Fit |

Connecting link plate Fastening method |

Precautions |

|---|---|---|---|---|

| RS roller chain | M-type connecting link | slip fit | spring clip Cotter pin Spring pin |

|

| F-type connecting link | press fit | spring clip and split pins Spring pin T-pin |

||

| Lambda Chain | M-type connecting link | slip fit | spring clip Cotter pin |

|

| Super chain Super-H chain |

M-type connecting link | slip fit | Spring pin |

|

| F-type connecting link | press fit | Spring pin |

|

|

| Ultra Super chain | F-type connecting link | press fit | Spring pin |

|

| RS-HT chain | M-type connecting link | slip fit | Split pin Spring pin |

|

| F-type connecting link | press fit | Split pin Spring pin |

|

|

| Catalogue description Other roller chains |

M-type connecting link | slip fit | spring clip and split pins Spring pin T-pins and Z-pins |

|

| Note) | |

| 1. | ring coin (RC) processing is a unique Tsubaki process that creates a plastically deformed area along the pin hole of the connecting link plate, with the aim of generating residual stress around the hole.Even with slip fit, there is no reduction in strength and the chain can be used with the same strength as the main chain. |

ring coin processing

| Note) | |

| 1. | Please refer to the dimension drawing for the types and sizes of roller chains that can be used with offset links. |

| 2. | The transmission capacity and maximum allowable load of offset links may be lower than that of the main chain. |