Significant torque increase: ECHT-FLEX NER series disc coupling

No assembly of the disc is required, and no disc replacement is required during maintenance.

ECHT-FLEX Coupling NER series does not require disk replacement when assembling into your equipment or disassembling for maintenance.

Reason why disc replacement is not necessary: Part 1: Torque transmission mechanism

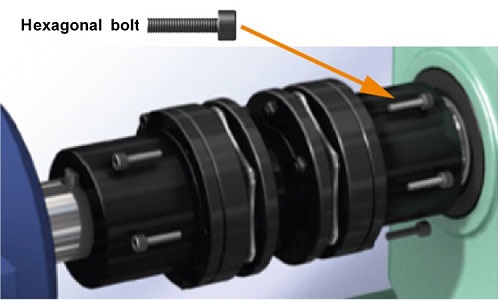

Torque is transmitted by friction

Tightening the U-nut generates axial force in the bolt, and torque is transmitted by the friction force between the hub, washer, and disc.

Since there are no sliding parts, there is no need to replace the disc during maintenance.

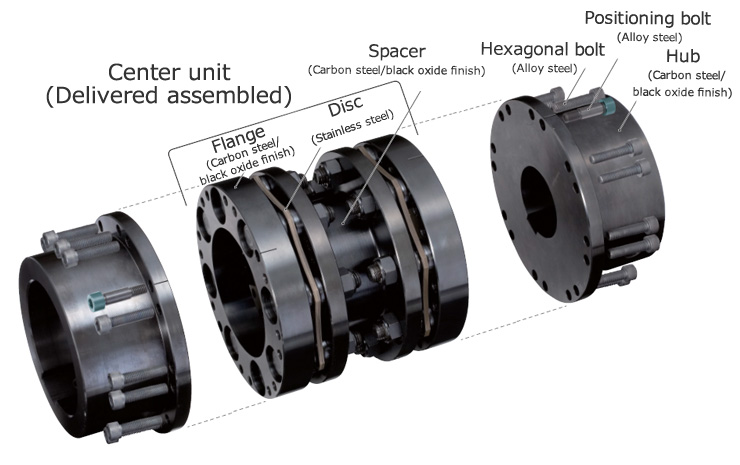

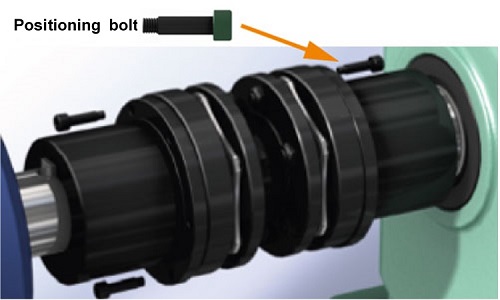

Reason why disc replacement is not necessary Part 2: Tsubaki's unique center unit structure

Conventional disc couplings required the user to assemble the disc section, but the NER series has a center unit structure, and the disc is shipped from the factory assembled with the spacer and flange.During maintenance, the disc section can be removed and attached without disassembly, eliminating the need for disc replacement.

advantage

- -No need to assemble the disc on site.

- - Can be tightened with a small torque wrench.

- · Eliminates the need to insert washers incorrectly or lose parts, reducing unnecessary man-hours.

- · Hub A can accommodate large shaft hole diameters.

- -The disc can be removed and attached without disassembling during maintenance.

[Examples of customer considerations]

Disc couplings are friction-based transmissions with no sliding parts, allowing for long-term use.

Furthermore, the NER series has a center unit structure, so assembly and disassembly of the disk section is not required.

There is usually no need to prepare a disk in advance for maintenance.

I'm having the pump inspected next month, so I need to prepare the coupling disc.

The disc part does not wear out and there is no need to disassemble it, so there is no need to prepare the disc!

Certainly, with this coupling, there is no need to change discs!