Overwhelming space saving and

Worm reducer that achieves weight reduction

Are you having trouble with something like this?

- Space is too small to install...

-

In order to move the load required for the device, the reducer would inevitably become too large to install inside the device.

Is there a compact, high-power reducer somewhere?

- I want to reduce rotation unevenness...

-

Any uneven rotation will affect the precision of the finished product.

Is there a reducer somewhere that has minimal rotational unevenness?

- I'm worried about the noise...

-

I would like to use it in equipment that requires quietness.

Is there a quiet reducer somewhere?

We will solve your problems!

High Performance

worm reducer

"Troi Drive"

↑ Play video

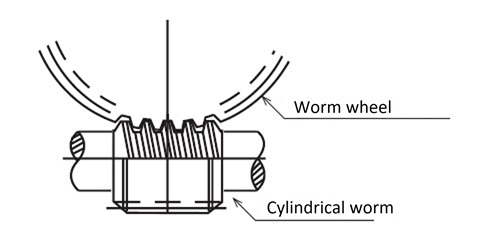

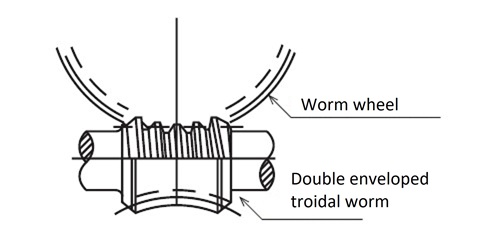

Worm reducers, which have a cylindrical worm gear, are known for their high load capacity, shock resistance, and quietness, even among general reducers. Troi Drive maximizes this performance.

The secret lies in the high-precision Troidal Worm, which is constricted to match the curve of the worm wheel.By significantly increasing the number of teeth that simultaneously mesh with the worm wheel, it achieves both a higher load capacity and higher efficiency than Cylindrical Worm.

Cylindrical Worm

Number of simultaneously engaged teeth: 1.7 to 2

Troidal Worm Gear

Number of simultaneously meshing teeth: 4 to 6.5

The number of simultaneously meshing teeth is

Because there are many,

High transmission and high efficiency!

Why choose Troi Drive

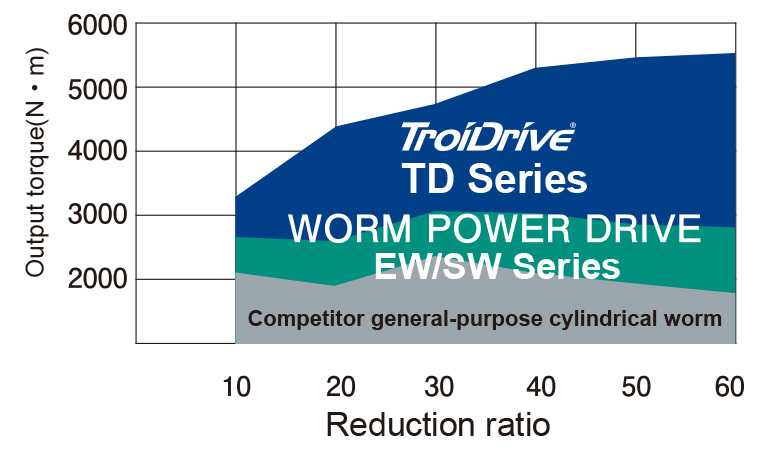

1. High power, lightweight and compact

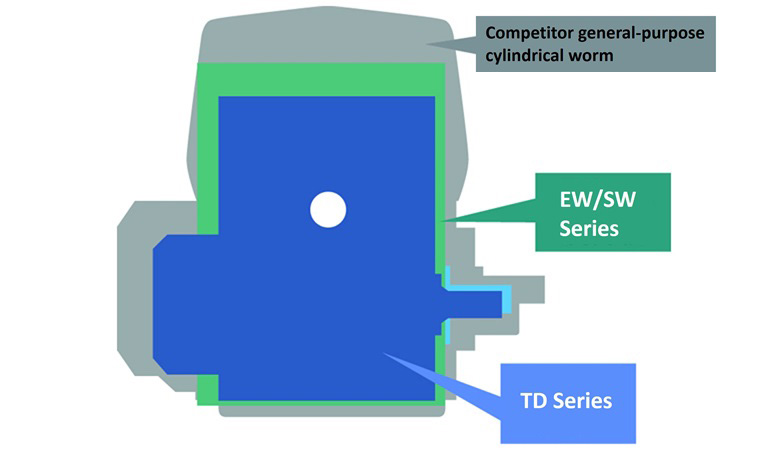

Generally, worm reducers can achieve a larger reduction ratio than other types of reducers, and are chosen for applications that require high load capacity. Among them, Troi Drive achieves a higher load capacity with its high-precision Troidal Worm. At the same size, it has 1.5 to 2 times the load capacity of a general-purpose Cylindrical Worm, so under the same load conditions, a frame size two sizes smaller can be selected.

Troi Drive is the most compact of all right-angle gear reducers, contributing to space-saving and lightweight equipment.

Torque comparison Size 200, input 1750 r/min

Thanks to its high load capacity, we were able to reduce the size of the reducer, which resulted in a more compact device!

2. Less rotation unevenness

Compared to general-purpose Cylindrical Worm reducers, Troi Drive has a greater number of simultaneously meshing teeth, resulting in less rotational irregularity and the smallest angular transmission error of any reducer that uses gears.

Comparison of simultaneous engagement teeth

|

4 to 6.5 pcs |

| General-purpose Cylindrical Worm | 1.7 to 2 pcs |

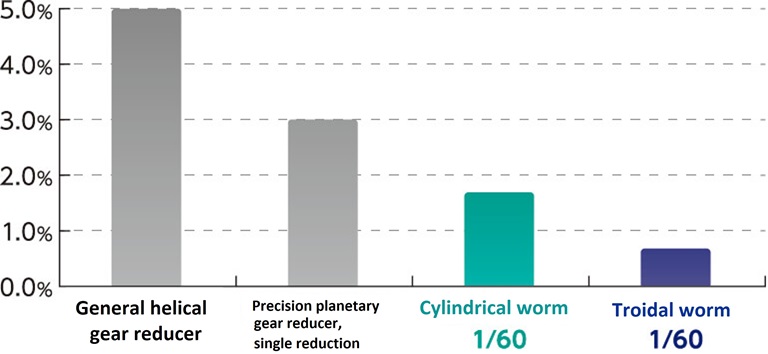

Angular velocity fluctuation rate

There is less rotational fluctuation compared to Cylindrical Worm reducers made by other companies, improving the precision of the final product!

3. Quiet and smooth operation

Unlike other types of reducers, worm reducers have sliding contact, which means they produce very little vibration or noise. Troi Drive has maximized tooth profile precision, resulting in even quieter, smoother rotation. Furthermore, for the same load capacity, the size can be made smaller than a general-purpose Cylindrical Worm reducer, further reducing noise.

It can be used safely even in applications where quietness is required!

Great for places like this!

Semiconductor/LED manufacturing process

Lapping machine

Troi Drive are used in the drive units of equipment used to polish silicon and sapphire wafers.

- Model used: TD125S20VRF

- Specifications: Center distance 125, reduction ratio 1/20

- Key Factor for Adoption

-

Small angular transmission error (uneven rotation)

The angular transmission error is approximately 1/10 compared to reduction mechanisms such as helical bevels, resulting in smoother rotation and improved finishes for the final product.

Secondary battery manufacturing process

Winding/unwinding, turret device

Troi Drive are used in the drive units of the device that applies electrode material to metal foil and the device that rolls it.

- Models used: TD150H60BRF, TD150H60BLF

- Specifications: Center distance 150, reduction ratio 1/60

- Key Factor for Adoption

-

Compact despite with a high reduction ratio

Compared to other types of reducers, worm reducers are compact and can achieve high reduction ratio. With Troi Drive, it is two sizes smaller than a general-purpose Cylindrical Worm reducer with the same load capacity.

-

Little rotation unevenness

By minimizing rotational irregularities, the electrode material film thickness becomes uniform, contributing to improved quality of the final product.

Rubber and resin manufacturing process

Calender roll

Troi Drive is used to adjust the gap between the calender rolls that smooth the surface of rubber and resin.

- Model used: TDM200H1800VL-RF370Y

- Specifications: Center distance 200, reduction ratio 1/1800, special motor integrated type

- Key Factor for Adoption

-

Compact and high power

The high transmission capacity of the Troidal worm gear contributes to space-saving equipment. In addition, the use of a 1/60 worm on the low-speed side provides self-locking (prevents reverse rotation), which makes it difficult for the reaction force of the load to be transmitted to the motor, preventing motor trouble.

Frequently asked questions

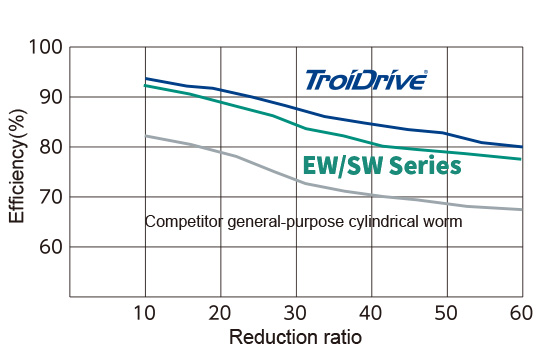

Q: How efficient is Troi Drive?

A: It depends on the reduction ratio and the rotation speed of the input shaft (motor).

The graph on the right shows an efficiency comparison for size 200 with an input of 1750 r/min. It is extremely efficient compared to other companies' general-purpose worms.

Q: I would like to replace a product from another company. Do you have any information available?

A: We have a website for replacements of equivalent products from other manufacturers, so please make use of it. When making a replacement, be sure to check the product catalog for details such as capacity, appearance, and dimensions.

Q: Are there any low backlash specifications?

A: Yes, we do. Backlash in the gear section is reduced by reducing the thrust gap of the worm shaft. It is possible to further reduce backlash by manufacturing a new reducer case or worm gear, so please contact us.

Q: What are the requirements for selection?

A: The main conditions for selecting a worm reducer are: 1. device name, 2. motor capacity and rotation speed, 3. output shaft torque or load torque, 4. output shaft rotation speed or reduction ratio, 5. output shaft shape and shaft arrangement, 6. output shaft load, 7. operating hours (per day), 8. number of starts (per hour), and 9. ambient temperature.

However, if the moment of inertia is large, or if it is used in an elevating drive or inverting mechanism, care must be taken. Please contact us for details.

If you have further questions, click here

Lineup

Series

- Troi Drive

Size (center to center)

- 125mm、150mm、175mm、200mm

225mm、255mm、280mm、315mm

Reduction ratio

- 1-stage reduction: 1/10, 1/20, 1/30, 1/40, 1/50, 1/60

- 2-stage reduction: 1/100 to 1/3600