technical data Synchronous Belts and Belt Sprockets

Instructions for use (Lock Belt Sprockets N type)

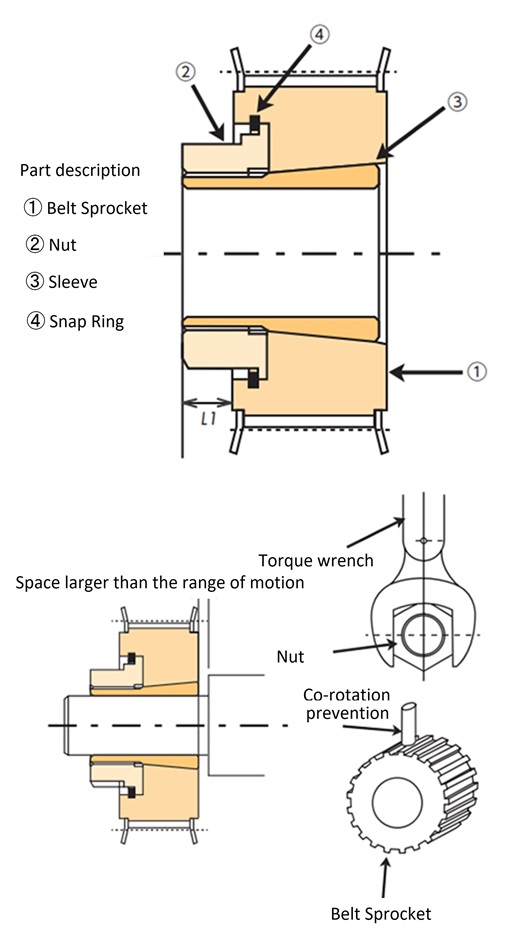

Instructions for use

Installation

- 1) Wipe off any dirt from the shaft surface and apply a thin layer of oil or grease. (Do not use oil or grease containing molybdenum-based anti-friction agents.)

- 2) The sleeve nut and retaining ring are assembled to the pulley body, so simply install them on the shaft as they are. If installation is difficult, turn the nut in the loosening direction. This will make installation easier.

When using the product after storing it for more than one month, remove the sleeve, wipe off any dirt adhering to the outer circumference of the sleeve, and apply oil or grease. (Do not use oil or grease containing molybdenum-based antifriction agents.) - 3) By preventing the rotation of the pulley body and manually tightening the nut Lock Belt Sprockets can be temporarily fixed in the specified position on the shaft or in the specified phase position.

- 4) Use a torque wrench to tighten the nut to the specified tightening torque M A (see table below).

- 5) When tightening the nut, be sure to ensure that the shaft or pulley body is prevented from rotating. One way to prevent the pulley body from rotating is to drill a hole on the outer periphery of the pulley and use a stop rod in the hole. (After drilling the hole, be sure to thoroughly remove any burrs.)

- 6) When tightening, the pulley body will move approximately 0.2 to 2.0 mm in the opposite direction to the nut, so please pay attention to the pulley alignment and shaft step.

Nut tightening torque M A

| Sleeve frame number | Nut flat width dimensions mm |

Nut tightening torque M A N・m {kgf・m} |

|---|---|---|

| N1 | 18 | 18 {1.84} |

| N2 | 22 | 28 {2.86} |

| N3 | 30 | 65 {6.63} |

| N4 | 36 | 100 {10.20} |

| N5 | 41 | 130 {13.27} |

| N6 | 46 | 200 {20.41} |

Removal

- 1) After confirming that no torque or thrust load is being applied to the pulley and shaft, loosen the nut.

- 2) When loosening the nut, be sure to stop the shaft or pulley body.

- 3) Loosening the nut will release the connection between the shaft and pulley.

General notes

- 1) Always use a torque wrench when tightening the nuts. Inaccurate tightening, such as by hand or by connecting pipes, will not only prevent accurate transmission torque but may also cause problems, so please refrain from doing so.

- 2) Operating temperature range: -15°C to 80°C (aluminum: 0°C to 50°C)

- 3) Please use the torque wrench correctly according to Instruction Manuals of the torque wrench you are using.

- 4) Shaft bore tolerance and surface roughness: The shaft diameter tolerance should be h8 and the shaft surface roughness should be Ra 3.2.