technical data Synchronous Belts and Belt Sprockets design data

Selection and design (Lock Belt Sprockets S type, S type plated specification)

Check the maximum transmission torque

Follow the steps below to select an S-type Lock Belt Sprockets.

The maximum torque and thrust load are calculated by multiplying the transmission capacity by Service factor.

Maximum torque T max

[SI units]

Tmax (N・m) = 9550 × KW × SF n

Gravity Units

Tmax (kgf・m) = 974 × KW × SF n

Maximum thrust load P max

Pmax (N{kgf}) = Pax × SF

- KW: Transmission capacity kW

- SF: Service factor (select from the table below)

- n: rotation speed r/min

- Pax: Maximum thrust load N{kgf}

When torque and thrust loads are applied simultaneously, calculate the combined load MR max using the following formula.

MR max = (T max) 2 + (P max × d /2000) 2 N・m{kgf・m} d: Shaft diameter (mm)

Compare the T max or MR max obtained above with the sleeve's transmission torque Mt.

It can be used if Mt ≧ T max or MR max.

Cannot be used if Mt < T max or MR max.

Service factor SF

| Load Condition | Service factor SF | |

|---|---|---|

| Smooth, shock-free transmission | Small load inertia Inertia ratio 1.0 or less |

1.2~1.5 |

| Transmission with light impact | During load inertia Inertia ratio 1.0~3.0 |

1.5~2.0 |

| High shock load Or forward/reverse |

Large load inertia Inertia ratio 3.0 or more |

2.0~5.0 |

Considering the axis

Use a shaft made of a material that satisfies the following formula.

δ0.2S ≧ 1.2 × P

δ 0.2S: Yield point of shaft material (MPa) P: Shaft side pressure (Mpa)

When using a hollow shaft, use a shaft with an inner diameter d B that satisfies the following formula.

dB ≦ d × δ0.2S - 2 × P δ0.2S

d: Shaft diameter (mm) δ 0.2S: Yield point of shaft material (MPa)

About the aluminum type

When using at low temperatures (below 0°C) or high temperatures (above 50°C), dimensional changes due to thermal expansion can cause misalignment between the belt and pulley, which can lead to early belt wear. Please contact us for details.

| [Reference] Thermal expansion coefficient | Specific gravity (g/cm 3) |

| Aluminum: 23.9 ×10 -6 | 2.8 |

| Carbon steel: 11.7 ×10 -6 | 7.8 |

Approximate mass

For standard installation, the estimated mass is the mass of Standard Stock Belt Sprockets plus the additional mass in the table.

For flat mounting, the approximate mass is Standard Stock Belt Sprockets mass minus the subtraction mass in the table.

| Sleeve frame number | Installation Method | |

|---|---|---|

| Standard installation | Flat mounting | |

| Additional mass kg | Subtracted mass kg | |

| S1 | 0.1 | 0.1 |

| S2 | 0.1 | 0.1 |

| S3 | 0.1 | 0.2 |

| S4 | 0.2 | 0.3 |

| S5 | 0.3 | 0.4 |

| S6 | 0.5 | 0.6 |

| S7 | 0.9 | 1.0 |

Sleeve specifications (Lock Belt Sprockets S type)

*Click to open and close.

Sleeve specifications (Lock Belt Sprockets S type)

*Click to open and close.

S type sleeve specification

| sleeve | Material | Carbon steel for machine structures |

|---|---|---|

| Heat Treatment | Quenching and tempering | |

| Fastening bolt | Hexagon socket head bolt (JIS B 1176) Strength classification: 12.9 |

|

| Material | structural alloy steel | |

| Heat Treatment | Quenching and tempering | |

| Surface Treatment | Black oxide coating | |

Sleeve Dimensions

| sleeve Frame number |

Shaft Hole Diameter d |

sleeve Outer diameter ΦD |

Mounting holes Pitch circle diameter ΦDF |

Taper Outer diameter ΦDK |

sleeve full length L |

flange Thickness T |

Straight section length t |

Bolt head height k |

Tightening bolt size |

screw holes | Tightening torque N・m {kgf・m} |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 10 | 32 | 24 | 18.6 | 18 | 6 | 2 | 4 | M4×16 | M4 | 4.2 {0.43} |

| 11 | |||||||||||

| 12 | |||||||||||

| 14 | |||||||||||

| 15 | |||||||||||

| 16 | |||||||||||

| S2 | 15 | 42 | 32 | 25.2 | 22 | 7 | 2 | 5 | M5×18 | M5 | 8.3 {0.85} |

| 16 | |||||||||||

| 17 | |||||||||||

| 18 | |||||||||||

| 19 | |||||||||||

| 20 | |||||||||||

| 22 | |||||||||||

| S3 | 24 | 48.5 | 38.5 | 31.2 | 23.5 | 8 | 2.5 | 5 | M5×20 | M5 | 8.3 {0.85} |

| 25 | |||||||||||

| 28 | |||||||||||

| S4 | 24 | 56 | 46 | 38.6 | 26 | 8 | 2.5 | 5 | M5×20 | M5 | 8.3 {0.85} |

| 25 | |||||||||||

| 28 | |||||||||||

| 30 | |||||||||||

| 32 | |||||||||||

| 35 | |||||||||||

| S5 | 35 | 66 | 56 | 48.8 | 29 | 10 | 2.5 | 5 | M5×22 | M5 | 8.3 {0.85} |

| 38 | |||||||||||

| 40 | |||||||||||

| 42 | |||||||||||

| 45 | |||||||||||

| S6 | 48 | 80 | 68 | 60 | 36 | 12 | 3 | 6 | M6×25 | M6 | 16.8 {1.71} |

| 50 | |||||||||||

| 55 | |||||||||||

| S7 | 60 | 101 | 86 | 75.5 | 40 | 13 | 3.5 | 8 | M8×30 | M8 | 40.5 {4.13} |

| 65 | |||||||||||

| 70 |

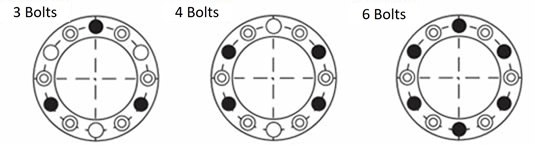

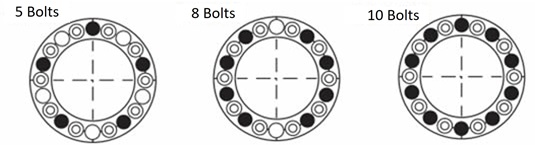

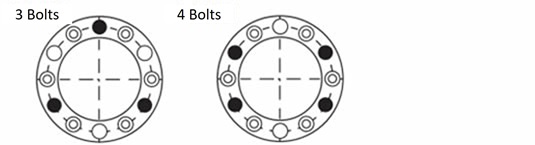

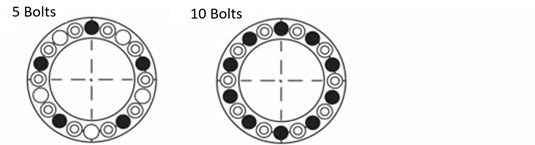

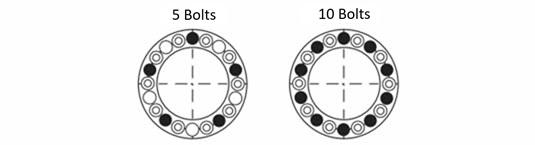

Tightening bolt usage position

・Use position of fastening bolt ○Open hole ◎Threaded hole (Threaded hole for removing sleeve)

| sleeve Frame number |

Position of tightening bolts | sleeve Frame number |

Position of tightening bolts |

|---|---|---|---|

| S1 |  |

S5 |  |

| S2 |  |

S6 |  |

| S3 |  |

S7 |  |

| S4 |  |

Sleeve specifications (Lock Belt Sprockets S type)

*Click to open and close.

Sleeve specifications (Lock Belt Sprockets S type)

*Click to open and close.

Sleeve Performance

| sleeve Frame number |

bolt Number |

Shaft Hole Diameter d mm |

bolt size |

Bolt tightening torque M.A. N・m {kgf・m} |

Transmission Torque Mt N・m {kgf・m} |

Thrust load Pax kN {kgf} |

Shaft side pressure P MPa {kgf/mm2} |

Hub side pressure P' MPa {kgf/mm2} |

Minimum hub diameter mm | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | ||||||||||||

| SS400 | S35C | S45C | A7075-T6 | |||||||||

| S1 | 3 | 10 | M4×16 | 4.2 {0.43} | 43 {4.4} | 8.6 {882} | 196 {20.0} | 111 {11.3} | 35 | 30 | 29 | 29 |

| 11 | 48 {4.8} | 8.6 {882} | 179 {18.2} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 12 | 52 {5.3} | 8.6 {882} | 164 {16.7} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 14 | 60 {6.2} | 8.6 {882} | 140 {14.3} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 15 | 65 {6.6} | 8.6 {882} | 131 {13.4} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 16 | 69 {7.1} | 8.6 {882} | 123 {12.5} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 4 | 10 | 58 {5.9} | 11.5 {1176} | 262 {26.7} | 148 {15.1} | 44 | 34 | 32 | 33 | |||

| 11 | 63 {6.5} | 11.5 {1176} | 238 {24.3} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 12 | 69 {7.1} | 11.5 {1176} | 218 {22.3} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 14 | 81 {8.2} | 11.5 {1176} | 187 {19.1} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 15 | 86 {8.8} | 11.5 {1176} | 175 {17.8} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 16 | 92 {9.4} | 11.5 {1176} | 164 {16.7} | 148 {15.1} | 44 | 34 | 32 | 33 | ||||

| 6 | 14 | 121 {12.3} | 17.3 {1764} | 281 {28.6} | 222 {22.6} | Not available | 49 | 42 | 44 | |||

| 15 | 130 {13.2} | 17.3 {1764} | 262 {26.7} | 222 {22.6} | Not available | 49 | 42 | 44 | ||||

| 16 | 138 {14.1} | 17.3 {1764} | 245 {25.0} | 222 {22.6} | Not available | 49 | 42 | 44 | ||||

| S2 | 3 | 15 | M5×18 | 8.3 {0.85} | 105 {10.7} | 13.9 {1423} | 163 {16.6} | 101 {10.3} | 45 | 39 | 38 | 38 |

| 16 | 112 {11.4} | 13.9 {1423} | 152 {15.5} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 17 | 119 {12.1} | 13.9 {1423} | 143 {14.6} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 18 | 126 {12.8} | 13.9 {1423} | 135 {13.8} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 19 | 133 {13.5} | 13.9 {1423} | 128 {13.1} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 20 | 139 {14.2} | 13.9 {1423} | 122 {12.4} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 22 | 153 {15.7} | 13.9 {1423} | 111 {11.3} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 4 | 15 | 139 {14.2} | 18.6 {1898} | 217 {22.1} | 135 {13.8} | 54 | 44 | 41 | 42 | |||

| 16 | 149 {15.2} | 18.6 {1898} | 203 {20.7} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 17 | 158 {16.1} | 18.6 {1898} | 191 {19.5} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 18 | 167 {17.1} | 18.6 {1898} | 181 {18.4} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 19 | 177 {18.0} | 18.6 {1898} | 171 {17.5} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 20 | 186 {19.0} | 18.6 {1898} | 163 {16.6} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 22 | 205 {20.9} | 18.6 {1898} | 148 {15.1} | 135 {13.8} | 54 | 44 | 41 | 42 | ||||

| 6 | 17 | 237 {24.2} | 27.9 {2846} | 287 {29.3} | 203 {20.7} | 124 | 59 | 52 | 54 | |||

| 18 | 251 {25.6} | 27.9 {2846} | 271 {27.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 19 | 265 {27.0} | 27.9 {2846} | 257 {26.2} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 20 | 279 {28.5} | 27.9 {2846} | 244 {24.9} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 22 | 307 {31.3} | 27.9 {2846} | 222 {22.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| S3 | 3 | 24 | M5×20 | 8.3 {0.85} | 167 {17.1} | 13.9 {1423} | 102 {10.4} | 81 {8.3} | 49 | 44 | 43 | 44 |

| 25 | 174 {17.8} | 13.9 {1423} | 98 {10.0} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 28 | 195 {19.9} | 13.9 {1423} | 87 {8.9} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 4 | 24 | 223 {22.8} | 18.6 {1898} | 135 {13.8} | 108 {11.0} | 56 | 49 | 47 | 47 | |||

| 25 | 232 {23.7} | 18.6 {1898} | 130 {13.3} | 108 {11.0} | 56 | 49 | 47 | 47 | ||||

| 28 | 260 {26.6} | 18.6 {1898} | 116 {11.8} | 108 {11.0} | 56 | 49 | 47 | 47 | ||||

| 6 | 24 | 335 {34.2} | 27.9 {2846} | 203 {20.7} | 162 {16.6} | 82 | 59 | 55 | 57 | |||

| 25 | 349 {35.6} | 27.9 {2846} | 195 {19.9} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| 28 | 391 {39.9} | 27.9 {2846} | 174 {17.8} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| S4 | 3 | 24 | M5×20 | 8.3 {0.85} | 167 {17.1} | 13.9 {1423} | 85 {8.7} | 55 {5.6} | 53 | 50 | 49 | 49 |

| 25 | 174 {17.8} | 13.9 {1423} | 82 {8.3} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 28 | 195 {19.9} | 13.9 {1423} | 73 {7.5} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 30 | 209 {21.3} | 13.9 {1423} | 68 {7.0} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 32 | 223 {22.8} | 13.9 {1423} | 64 {6.5} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 35 | 244 {24.9} | 13.9 {1423} | 58 {6.0} | 55 {5.6} | 53 | 50 | 49 | 49 | ||||

| 4 | 24 | 223 {22.8} | 18.6 {1898} | 114 {11.6} | 73 {7.5} | 58 | 53 | 51 | 52 | |||

| 25 | 232 {23.7} | 18.6 {1898} | 109 {11.1} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 28 | 260 {26.6} | 18.6 {1898} | 97 {9.9} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 30 | 279 {28.5} | 18.6 {1898} | 91 {9.3} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 32 | 298 {30.4} | 18.6 {1898} | 85 {8.7} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 35 | 325 {33.2} | 18.6 {1898} | 78 {7.9} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 6 | 24 | 335 {34.2} | 27.9 {2846} | 170 {17.4} | 110 {11.2} | 69 | 59 | 57 | 58 | |||

| 25 | 349 {35.6} | 27.9 {2846} | 164 {16.7} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 28 | 391 {39.9} | 27.9 {2846} | 146 {14.9} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 30 | 418 {42.7} | 27.9 {2846} | 136 {13.9} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 32 | 446 {45.5} | 27.9 {2846} | 128 {13.0} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 35 | 488 {49.8} | 27.9 {2846} | 117 {11.9} | 110 {11.2} | 69 | 59 | 57 | 58 | ||||

| 8 | 24 | 446 {45.5} | 37.2 {3795} | 227 {23.2} | 146 {14.9} | 88 | 68 | 64 | 65 | |||

| 25 | 465 {47.4} | 37.2 {3795} | 218 {22.3} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 28 | 521 {53.1} | 37.2 {3795} | 195 {19.9} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 30 | 558 {56.9} | 37.2 {3795} | 182 {18.5} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 32 | 595 {60.7} | 37.2 {3795} | 170 {17.4} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 35 | 651 {66.4} | 37.2 {3795} | 156 {15.9} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| S5 | 5 | 35 | M5×22 | 8.3 {0.85} | 407 {41.5} | 23.2 {2372} | 91 {9.3} | 68 {6.9} | 70 | 64 | 63 | 63 |

| 38 | 442 {45.1} | 23.2 {2372} | 84 {8.6} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 40 | 465 {47.4} | 23.2 {2372} | 80 {8.2} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 42 | 488 {49.8} | 23.2 {2372} | 76 {7.8} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 45 | 523 {53.4} | 23.2 {2372} | 71 {7.3} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 8 | 35 | 651 {66.4} | 37.2 {3795} | 146 {14.9} | 108 {11.0} | 86 | 74 | 71 | 72 | |||

| 38 | 707 {72.1} | 37.2 {3795} | 135 {13.8} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 40 | 744 {75.9} | 37.2 {3795} | 128 {13.1} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 42 | 781 {79.7} | 37.2 {3795} | 122 {12.4} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 45 | 837 {85.4} | 37.2 {3795} | 114 {11.6} | 108 {11.0} | 86 | 74 | 71 | 72 | ||||

| 10 | 35 | 814 {83.0} | 46.5 {4744} | 183 {18.7} | 135 {13.8} | 102 | 81 | 77 | 78 | |||

| 38 | 883 {90.1} | 46.5 {4744} | 169 {17.2} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 40 | 930 {94.9} | 46.5 {4744} | 160 {16.3} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 42 | 976 {99.6} | 46.5 {4744} | 152 {15.6} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 45 | 1046 {106.7} | 46.5 {4744} | 142 {14.5} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| S6 | 6 | 48 | M6×25 | 16.8 {1.71} | 1116 {113.9} | 46.5 {4744} | 105 {10.7} | 87 {8.8} | 94 | 84 | 81 | 82 |

| 50 | 1162 {118.6} | 46.5 {4744} | 101 {10.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 55 | 1279 {130.5} | 46.5 {4744} | 91 {9.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 8 | 48 | 1488 {151.8} | 62.0 {6326} | 140 {14.3} | 115 {11.8} | 110 | 93 | 88 | 90 | |||

| 50 | 1550 {158.1} | 62.0 {6326} | 134 {13.7} | 115 {11.8} | 110 | 93 | 88 | 90 | ||||

| 55 | 1705 {174.0} | 62.0 {6326} | 122 {12.4} | 115 {11.8} | 110 | 93 | 88 | 90 | ||||

| 10 | 48 | 1860 {189.8} | 77.5 {7907} | 175 {17.8} | 144 {14.7} | 134 | 103 | 97 | 99 | |||

| 50 | 1937 {197.7} | 77.5 {7907} | 168 {17.1} | 144 {14.7} | 134 | 103 | 97 | 99 | ||||

| 55 | 2131 {217.4} | 77.5 {7907} | 152 {15.6} | 144 {14.7} | 134 | 103 | 97 | 99 | ||||

| 12 | 48 | 2232 {227.7} | 93.0 {9488} | 210 {21.4} | 173 {17.7} | 174 | 117 | 107 | 110 | |||

| 50 | 2325 {237.2} | 93.0 {9488} | 201 {20.5} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| 55 | 2557 {260.9} | 93.0 {9488} | 183 {18.7} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| S7 | 5 | 60 | M8×30 | 40.5 {4.13} | 2140 {218.4} | 71.3 {7280} | 115 {11.7} | 94 {9.6} | 124 | 109 | 105 | 107 |

| 65 | 2319 {236.6} | 71.3 {7280} | 106 {10.8} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 70 | 2497 {254.8} | 71.3 {7280} | 99 {10.1} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 8 | 60 | 3424 {349.4} | 114.1 {11648} | 184 {18.8} | 150 {15.3} | 177 | 134 | 125 | 128 | |||

| 65 | 3710 {378.6} | 114.1 {11648} | 170 {17.3} | 150 {15.3} | 177 | 134 | 125 | 128 | ||||

| 70 | 3995 {407.7} | 114.1 {11648} | 158 {16.1} | 150 {15.3} | 177 | 134 | 125 | 128 | ||||

| 10 | 60 | 4281 {436.8} | 142.7 {14560} | 230 {23.5} | 188 {19.2} | 270 | 159 | 143 | 149 | |||

| 65 | 4637 {473.2} | 142.7 {14560} | 212 {21.7} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||

| 70 | 4994 {509.6} | 142.7 {14560} | 197 {20.1} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||

Sleeve specifications (Lock Belt Sprockets S type plated)

*Click to open and close.

Sleeve specifications (Lock Belt Sprockets S type plated)

*Click to open and close.

S type Plated sleeve specification

| sleeve | Material | Carbon steel for machine structures |

|---|---|---|

| Heat Treatment | Quenching and tempering | |

| Surface Treatment | Electroless nickel-phosphorus plating | |

| Fastening bolt | Hexagon socket head bolt (JIS B 1176) Strength classification: 12.9 |

|

| Material | structural alloy steel | |

| Heat Treatment | Quenching and tempering | |

| Surface Treatment | Special Coating | |

Sleeve Dimensions

| sleeve Frame number |

Shaft Hole Diameter d |

sleeve Outer diameter ΦD |

Mounting holes Pitch circle diameter ΦDF |

Taper Outer diameter ΦDK |

sleeve full length L |

flange Thickness T |

Straight section length t |

Bolt head height k |

Tightening bolt size |

|---|---|---|---|---|---|---|---|---|---|

| S1 | 10 | 32 | 24 | 18.6 | 18 | 6 | 2 | 4 | M4×16 |

| 11 | |||||||||

| 12 | |||||||||

| 14 | |||||||||

| 15 | |||||||||

| 16 | |||||||||

| S2 | 17 | 42 | 32 | 25.2 | 22 | 7 | 2 | 5 | M5×20 |

| 18 | |||||||||

| 19 | |||||||||

| 20 | |||||||||

| 22 | |||||||||

| S3 | 24 | 48.5 | 38.5 | 31.2 | 23.5 | 8 | 2.5 | 5 | M5×20 |

| 25 | |||||||||

| 28 | |||||||||

| S4 | 30 | 56 | 46 | 38.6 | 26 | 8 | 2.5 | 5 | M5×20 |

| 32 | |||||||||

| 35 | |||||||||

| S5 | 38 | 66 | 56 | 48.8 | 29 | 10 | 2.5 | 5 | M5×25 |

| 40 | |||||||||

| 42 | |||||||||

| 45 | |||||||||

| S6 | 48 | 80 | 68 | 60 | 36 | 12 | 3 | 6 | M6×25 |

| 50 | |||||||||

| 55 | |||||||||

| S7 | 60 | 101 | 86 | 75.5 | 40 | 13 | 3.5 | 8 | M8×30 |

| 65 | |||||||||

| 70 |

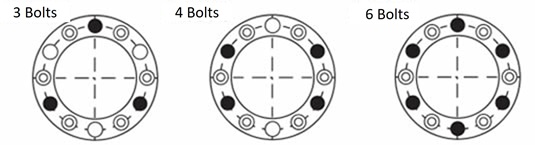

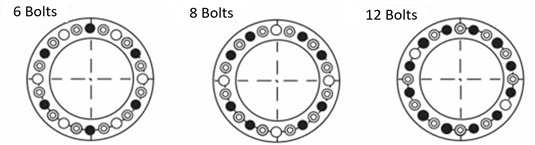

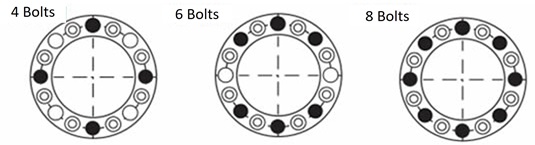

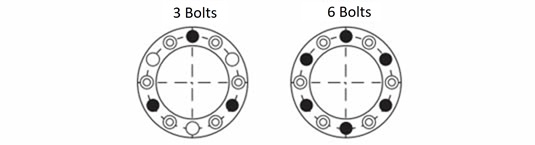

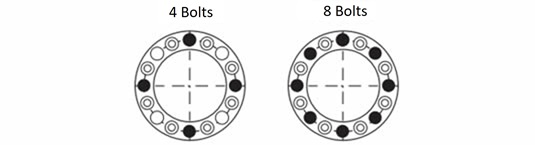

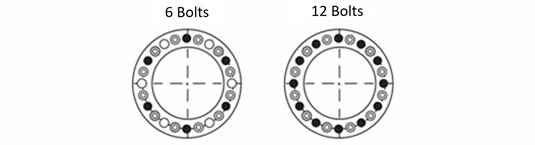

Tightening bolt usage position

・Use position of fastening bolt ○Open hole ◎Threaded hole (Threaded hole for removing sleeve)

| sleeve Frame number |

Position of tightening bolts | sleeve Frame number |

Position of tightening bolts |

|---|---|---|---|

| S1 S2 S3 |

|

S5 S7 |

|

| S4 |  |

S6 |  |

Sleeve specifications (Lock Belt Sprockets S type plated)

*Click to open and close.

Sleeve specifications (Lock Belt Sprockets S type plated)

*Click to open and close.

Sleeve Performance

| sleeve Frame number |

bolt Number |

Shaft Hole Diameter d mm |

bolt size |

Bolt tightening torque M.A. N・m {kgf・m} |

Transmission Torque Mt N・m {kgf・m} |

Thrust load Pax kN {kgf} |

Shaft side pressure P MPa {kgf/mm2} |

Hub side pressure P' MPa {kgf/mm2} |

Minimum hub diameter mm | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | ||||||||||||

| SS400 | S35C | S45C | A7075-T6 | |||||||||

| S1 | 3 | 10 | M4×16 | 3.4 {0.35} | 43 {4.4} | 8.6 {882} | 196 {20.0} | 111 {11.3} | 35 | 30 | 29 | 29 |

| 11 | 48 {4.8} | 8.6 {882} | 179 {18.2} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 12 | 52 {5.3} | 8.6 {882} | 164 {16.7} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 14 | 60 {6.2} | 8.6 {882} | 140 {14.3} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 15 | 65 {6.6} | 8.6 {882} | 131 {13.4} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 16 | 69 {7.1} | 8.6 {882} | 123 {12.5} | 111 {11.3} | 35 | 30 | 29 | 29 | ||||

| 6 | 14 | 121 {12.3} | 17.3 {1764} | 281 {28.6} | 222 {22.6} | Not available | 49 | 42 | 44 | |||

| 15 | 130 {13.2} | 17.3 {1764} | 262 {26.7} | 222 {22.6} | Not available | 49 | 42 | 44 | ||||

| 16 | 138 {14.1} | 17.3 {1764} | 245 {25.0} | 222 {22.6} | Not available | 49 | 42 | 44 | ||||

| S2 | 3 | 17 | M5×20 | 6.8 {0.69} | 119 {12.1} | 13.9 {1423} | 143 {14.6} | 101 {10.3} | 45 | 39 | 38 | 38 |

| 18 | 126 {12.8} | 13.9 {1423} | 135 {13.8} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 19 | 133 {13.5} | 13.9 {1423} | 128 {13.1} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 20 | 139 {14.2} | 13.9 {1423} | 122 {12.4} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 22 | 153 {15.7} | 13.9 {1423} | 111 {11.3} | 101 {10.3} | 45 | 39 | 38 | 38 | ||||

| 6 | 17 | 237 {24.2} | 27.9 {2846} | 287 {29.3} | 203 {20.7} | 124 | 59 | 52 | 54 | |||

| 18 | 251 {25.6} | 27.9 {2846} | 271 {27.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 19 | 265 {27.0} | 27.9 {2846} | 257 {26.2} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 20 | 279 {28.5} | 27.9 {2846} | 244 {24.9} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| 22 | 307 {31.3} | 27.9 {2846} | 222 {22.6} | 203 {20.7} | 124 | 59 | 52 | 54 | ||||

| S3 | 3 | 24 | M5×20 | 6.8 {0.69} | 167 {17.1} | 13.9 {1423} | 102 {10.4} | 81 {8.3} | 49 | 44 | 43 | 44 |

| 25 | 174 {17.8} | 13.9 {1423} | 98 {10.0} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 28 | 195 {19.9} | 13.9 {1423} | 87 {8.9} | 81 {8.3} | 49 | 44 | 43 | 44 | ||||

| 6 | 24 | 335 {34.2} | 27.9 {2846} | 203 {20.7} | 162 {16.6} | 82 | 59 | 55 | 57 | |||

| 25 | 349 {35.6} | 27.9 {2846} | 195 {19.9} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| 28 | 391 {39.9} | 27.9 {2846} | 174 {17.8} | 162 {16.6} | 82 | 59 | 55 | 57 | ||||

| S4 | 4 | 30 | M5×20 | 6.8 {0.69} | 279 {28.5} | 18.6 {1898} | 91 {9.3} | 73 {7.5} | 58 | 53 | 51 | 52 |

| 32 | 298 {30.4} | 18.6 {1898} | 85 {8.7} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 35 | 325 {33.2} | 18.6 {1898} | 78 {7.9} | 73 {7.5} | 58 | 53 | 51 | 52 | ||||

| 8 | 30 | 558 {56.9} | 37.2 {3795} | 182 {18.5} | 146 {14.9} | 88 | 68 | 64 | 65 | |||

| 32 | 595 {60.7} | 37.2 {3795} | 170 {17.4} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| 35 | 651 {66.4} | 37.2 {3795} | 156 {15.9} | 146 {14.9} | 88 | 68 | 64 | 65 | ||||

| S5 | 5 | 38 | M5×25 | 6.8 {0.69} | 442 {45.1} | 23.2 {2372} | 84 {8.6} | 68 {6.9} | 70 | 64 | 63 | 63 |

| 40 | 465 {47.4} | 23.2 {2372} | 80 {8.2} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 42 | 488 {49.8} | 23.2 {2372} | 76 {7.8} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 45 | 523 {53.4} | 23.2 {2372} | 71 {7.3} | 68 {6.9} | 70 | 64 | 63 | 63 | ||||

| 10 | 38 | 883 {90.1} | 46.5 {4744} | 169 {17.2} | 135 {13.8} | 102 | 81 | 77 | 78 | |||

| 40 | 930 {94.9} | 46.5 {4744} | 160 {16.3} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 42 | 976 {99.6} | 46.5 {4744} | 152 {15.6} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| 45 | 1046 {106.7} | 46.5 {4744} | 142 {14.5} | 135 {13.8} | 102 | 81 | 77 | 78 | ||||

| S6 | 6 | 48 | M6×25 | 13.6 {1.39} | 1116 {113.9} | 46.5 {4744} | 105 {10.7} | 87 {8.8} | 94 | 84 | 81 | 82 |

| 50 | 1162 {118.6} | 46.5 {4744} | 101 {10.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 55 | 1279 {130.5} | 46.5 {4744} | 91 {9.3} | 87 {8.8} | 94 | 84 | 81 | 82 | ||||

| 12 | 48 | 2232 {227.7} | 93.0 {9488} | 210 {21.4} | 173 {17.7} | 174 | 117 | 107 | 110 | |||

| 50 | 2325 {237.2} | 93.0 {9488} | 201 {20.5} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| 55 | 2557 {260.9} | 93.0 {9488} | 183 {18.7} | 173 {17.7} | 174 | 117 | 107 | 110 | ||||

| S7 | 5 | 60 | M8×30 | 32.8 {3.35} | 2140 {218.4} | 71.3 {7280} | 115 {11.7} | 94 {9.6} | 124 | 109 | 105 | 107 |

| 65 | 2319 {236.6} | 71.3 {7280} | 106 {10.8} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 70 | 2497 {254.8} | 71.3 {7280} | 99 {10.1} | 94 {9.6} | 124 | 109 | 105 | 107 | ||||

| 10 | 60 | 4281 {436.8} | 142.7 {14560} | 230 {23.5} | 188 {19.2} | 270 | 159 | 143 | 149 | |||

| 65 | 4637 {473.2} | 142.7 {14560} | 212 {21.7} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||

| 70 | 4994 {509.6} | 142.7 {14560} | 197 {20.1} | 188 {19.2} | 270 | 159 | 143 | 149 | ||||