technical data Small size conveyor chain Sprockets Handling

Installation

1. Installing the sprocket

The quality of sprocket installation has a major impact on the smooth operation of the conveyor and determines the lifespan of small size conveyor chain with attachments.

Please install correctly according to the following procedure.

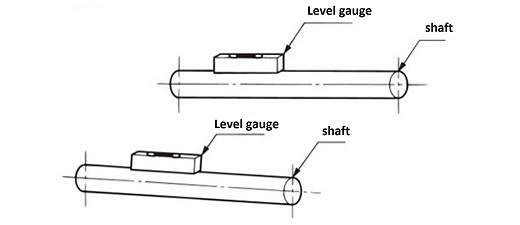

(1) Use a spirit level to make sure the shaft is level.

The accuracy is adjusted to within ±1,300.

Figure 1. Shaft levelness

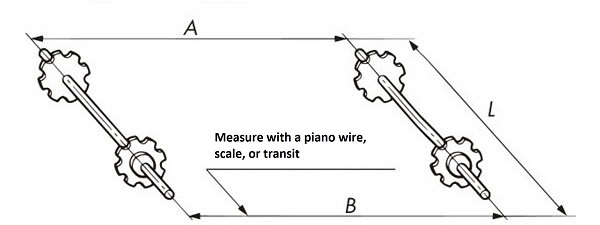

(2) Determine the parallelism of the shaft.

The accuracy of ABL is adjusted to within ±1,100.

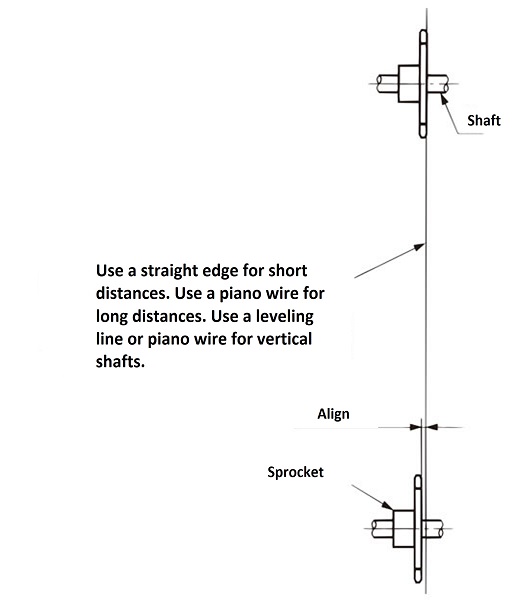

(3) Correct any misalignment between the sprockets.

- Up to 1m shaft distance: within 1mm

- Center distance 1m to 10m: Center distance (mm) within 1000

- Center distance 10m or more: within 10mm

Figure 3. Misaligned sprockets

(4) After adjusting steps (1) to (3), secure the sprocket to the shaft using a key or Tsubaki Power-Lock.

Sprockets used in parallel are fixed so that the two teeth on the shaft center are in phase.

2. Centering

In chain conveyors, the chain runs along guide rails, so the rails must be manufactured with particularly high precision and be centered accurately.

In the case of vertical bucket elevators that do not have guide rails, if the conveyor is not centered correctly, the chain will snake, significantly affecting the chain's lifespan.

3. Rails

Generally, rail wear occurs faster than chain wear.

The rail material and chain material combination are important, but we generally recommend general structural rolled steel (SS400) or plastic (ultra-high molecular weight polyethylene).

- (1) Wear is a complex process that involves various factors (corrosion, lubrication, load speed, operating time, etc.). It is difficult to accurately estimate the relationship between chain life and rail material.

- (2) Chain life depends on the combination with the rail. For new installations, check the wear condition with rail material that is slightly softer than the chain. It is best to use a smooth finish on the rail surface.

- (3) When deciding on a material, consider the conditions of use. Plastic may not be usable when subjected to shocks or in special environments.

- (4) Precautions regarding rails before operation

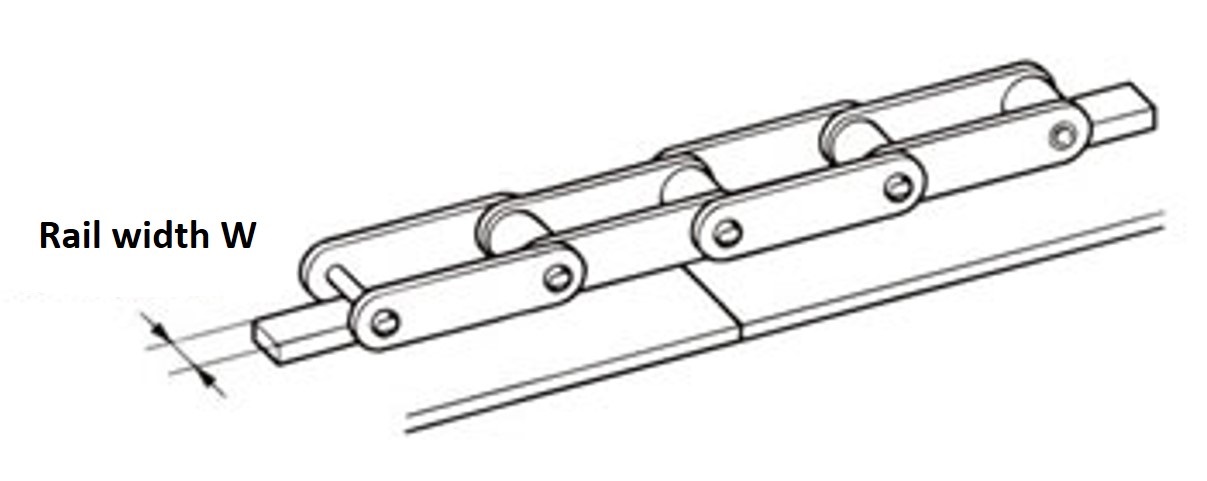

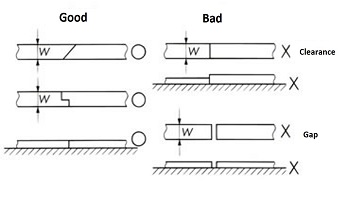

- 1. Rail joints should be smooth, with no edges, steps, or gaps (Fig. 4).

- 2. Remove any spatter or scale that may have been produced during welding.

- 3. During a test run, oil the chain with no load and check the condition of the chain and rail.

Rail width W: Generally, this is the sprocket tooth width.

A gap is necessary to take into account the thermal expansion of the rails.

Figure 4. Rail connection

At the entrance and exit of the chain, the rail is curved to ensure smooth chain movement.

Figure 5. Chain entrance/exit rail