technical data linear actuator Zip Chain Actuator Handling

Servo motor assembly procedure for TERVO servo motor reducer

When the motor shaft is round (input shaft clamp type)

- 1. Install the reducer so that the motor mounting surface is at the top.

- 2. Wipe off any rust, dust, or rust-preventive oil from the motor shaft.

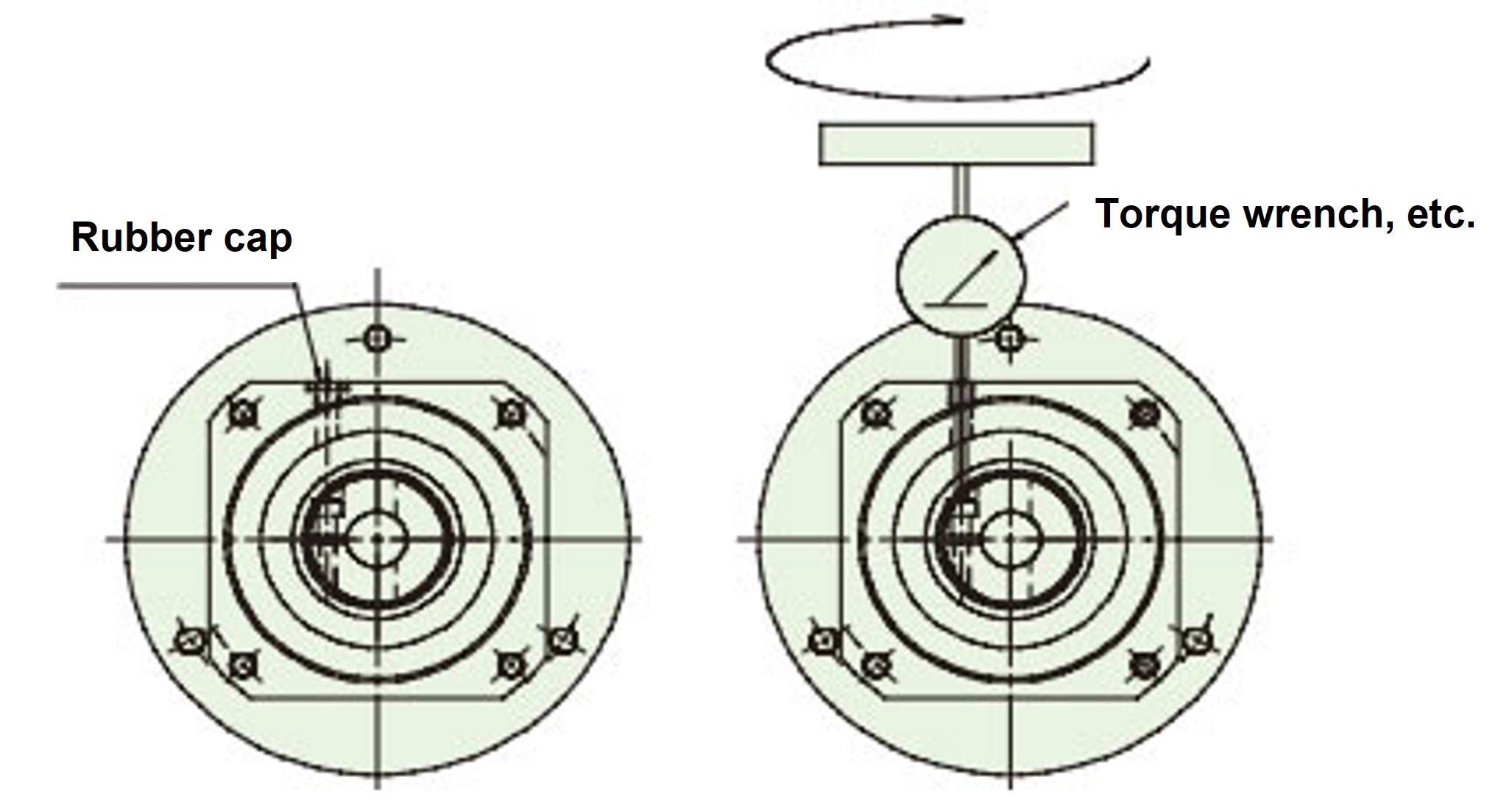

- 3. Remove the rubber cap from the flange, and turn the input shaft to align the bolt head with the hole position.

Use an L-spanner or similar tool to check that the set bolt is loose. - 4. Insert the motor shaft smoothly into the input shaft. Be careful not to insert the motor shaft at an angle.

- 5. After the spigot part is fully inserted, secure it completely to the flange using the appropriate bolts and tightening torque.

- 6. Use a torque wrench to tighten the set bolt on the input shaft to the specified tightening torque.

- 7. Attach the rubber cap. This completes the motor installation.

Tightening the clamp set bolt

Mounting a keyed motor to an input shaft clamp type

Motor shafts with keys can be used as clamp types in the same way as round shafts by removing the key.

Set the motor keyway (D cut) 180 degrees opposite the position of the slit in the clamp.

Install the reducer using the same procedure as for the round shaft.

| Servo motor capacity (target model number) | Set bolt size | Tightening torque |

|---|---|---|

| 200W(020)・400W(040) | M4 | 4.1N・m{0.41kgf・m} |

| 750W(075) | M5 | 8.5N・m{0.85kgf・m} |