technical data linear actuator Zip Chain Actuator Hypoid Motor with Inverter DriveNotes

Precautions for inverter drive

ZCA25M: Motor capacity 60W-90W

- ・The 200V class can be inverter-driven, but cannot be used at low frequencies or above 60Hz. Also, the 400V class cannot be inverter-driven.

ZCA35M/ZCA45M: Motor capacity 0.2kW/0.4kW/0.75kW

- - The maximum operating frequency is 120 Hz, and the low Hz range (low frequency) should be used within the allowable range of the inverter. The 0.75 kW motor type is also capable of constant torque operation between 6 Hz and 60 Hz using a standard motor.

- ・At high speeds, torque decreases in inverse proportion to rotation speed because kW remains constant. Also, as rotation speed increases, motor noise, motor fan noise, reduction gear noise, vibration, etc. increase.

- At low speeds, the motor's operating efficiency and cooling effect decrease, resulting in a large temperature rise. Please reduce the torque when using the motor.

The output torque (%) is 100% of the motor's rated value at 60Hz.

(Base frequency set to 60Hz)

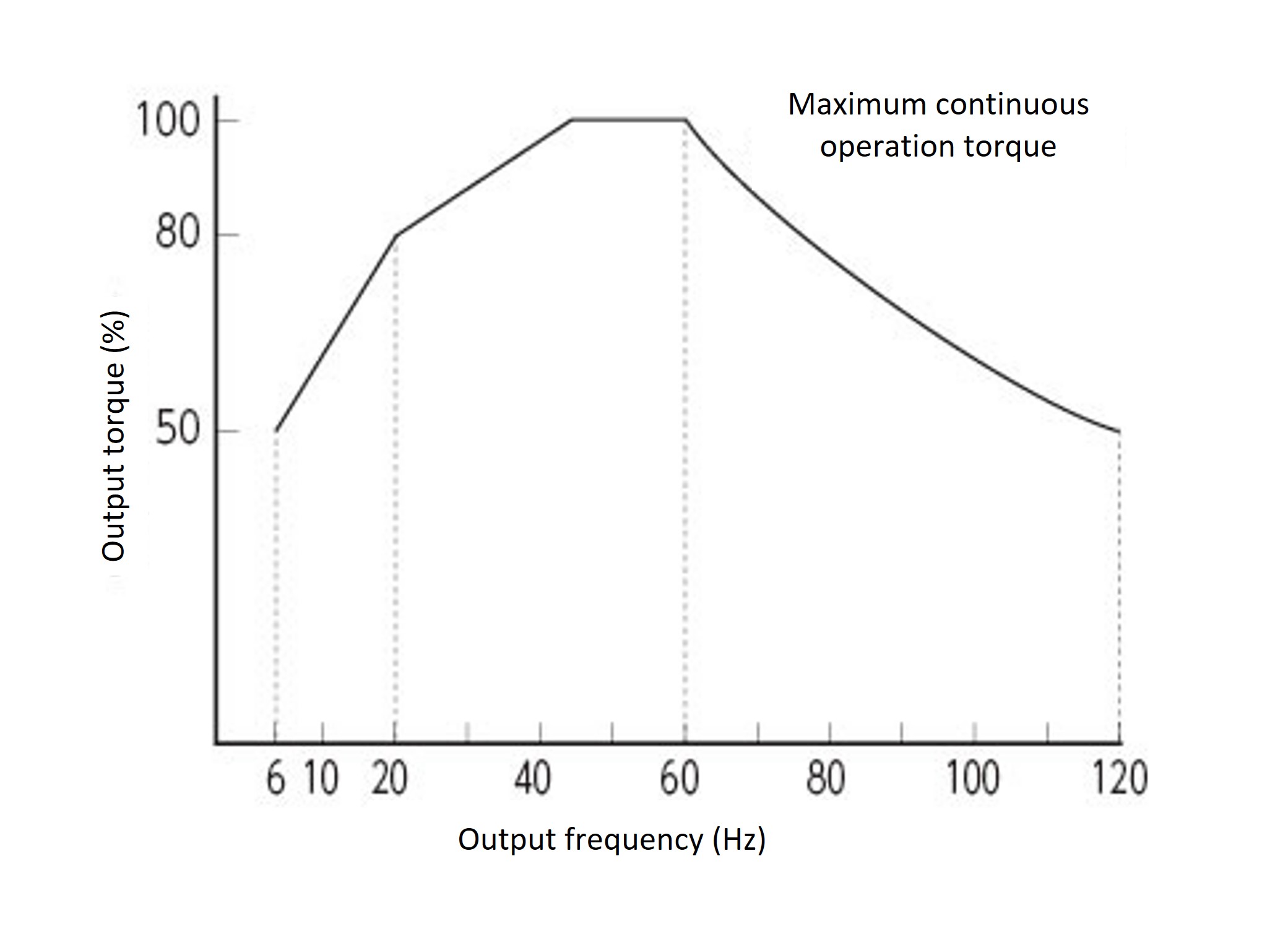

For 0.2kW and 0.4kW motors

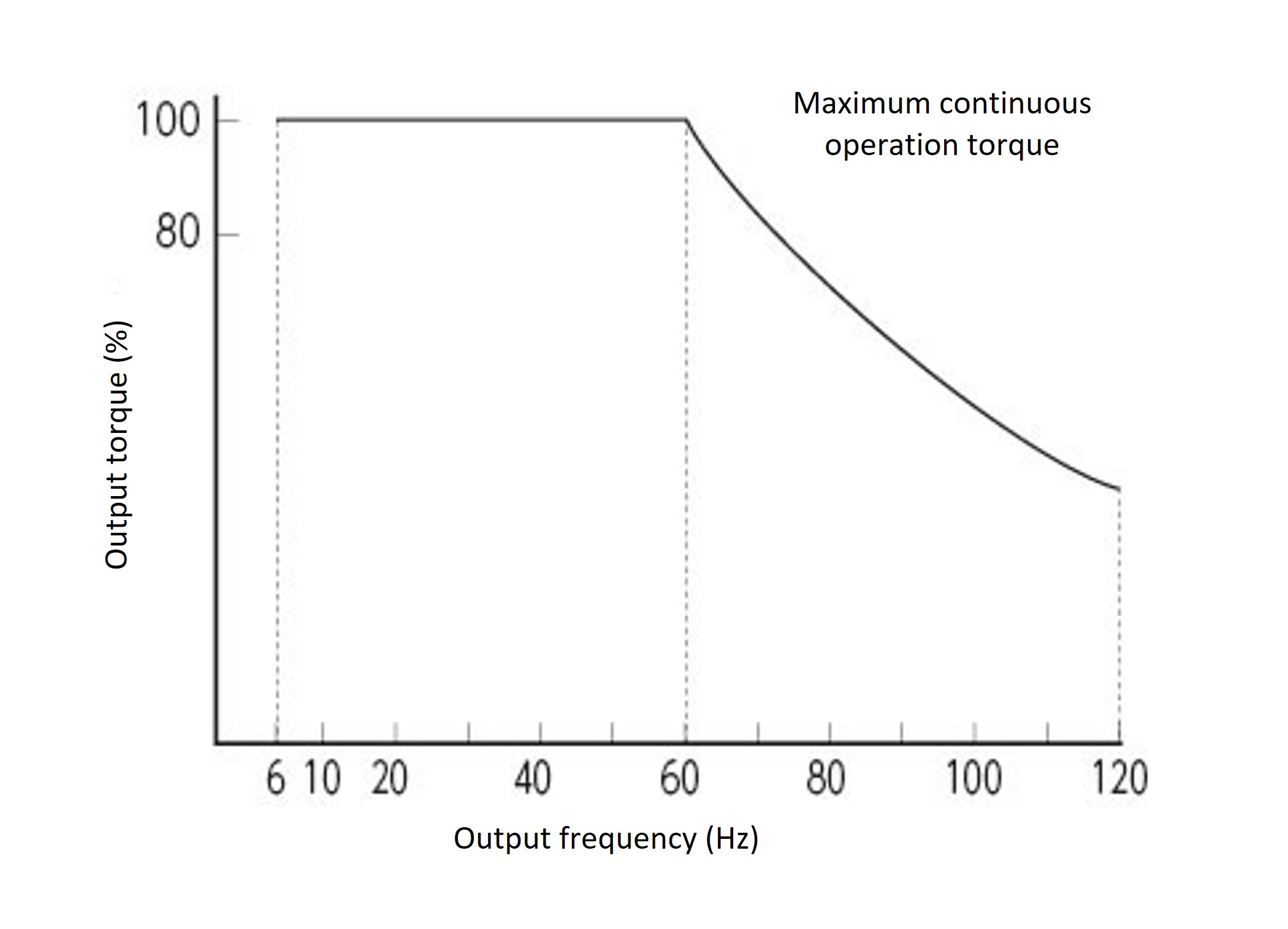

The output torque (%) is 100% of the motor's rated value at 60Hz.

(Base frequency set to 60Hz)

For a 0.75kW motor

Points to note when braking

- ・The brake requires a specific power supply (frequency, voltage), so the brake circuit must be operated separately. For details, see "Wiring a motor with a brake."

- - With standard products, the brake lead wires are shipped with screws fastened to the motor lead wires, but please remove the screws and connect them separately.

- - When braking, please keep the speed below 60Hz (1800 r/min). Braking at high speeds above 60Hz can cause mechanical damage, abnormal wear and heat generation in the lining, and other problems, so always operate at 60Hz or below.

When driving a 400V class motor with an inverter

- - 400V class motors are available as special models. 400V class motors can suffer from insulation breakdown due to the effects of high-voltage surges (microsurges) generated by inverter switching. Therefore, measures to prevent this (microsurge countermeasures) are required for the motor, and our 400V class motors are equipped with microsurge countermeasures even if not specified. However, if the level exceeds 1250V, please install a suppression filter or reactor on the inverter side.

Other points to note

- - Temperature rise, noise and vibration will be greater than when using commercial power.

- To protect the motor from overheating, set the electronic thermal to general-purpose motor characteristics or install a thermal relay between the inverter and motor.

- When using a base frequency of 50Hz, the output torque should be 0.8 times the value in the table above (0.2kW and 0.4kW only).

- ・Inverter motors are also available for 0.2kW and 0.4kW.