technical data linear actuator Power Cylinder Selection

Selection: U Series Multi-Specification

Requirements

Machines used and how to use them

Thrust or load N{kgf}

Stroke mm

Speed mm/s

Frequency of use Number of starts/min

Usage time: hours/day and annual operating days: days/year

The nature of the load on the machine used

Usage environment

Selection Procedure

- 1. Decide the type (A or C) based on how you will use it.

- 2. Calculate Service factor based on the nature of the load and the machine being used.

- 3. Calculate the annual travel distance based on the stroke, frequency of use, and duration of use.

Annual travel distance km = Actual stroke m × frequency of use/day × number of operating days/year × 10-3

- 4. If the load fluctuates significantly midway through the stroke, calculate the equivalent load using the following formula.

PM = PMIN + 2×PMAX 3

P M: Equivalent load N{kgf}

P MIN: Minimum load N{kgf}

P MAX: Maximum load N{kgf}

- 5. Multiply the maximum load of the device by Service factor, and in the case of linked operation, divide by Multiple factor and the number of linked units to obtain the corrected thrust.

Corrected thrust = Maximum load of device x Service factor Number of linked units x Multiple factor

- 6. Select the model number to be used from the standard models based on the corrected thrust and stroke.

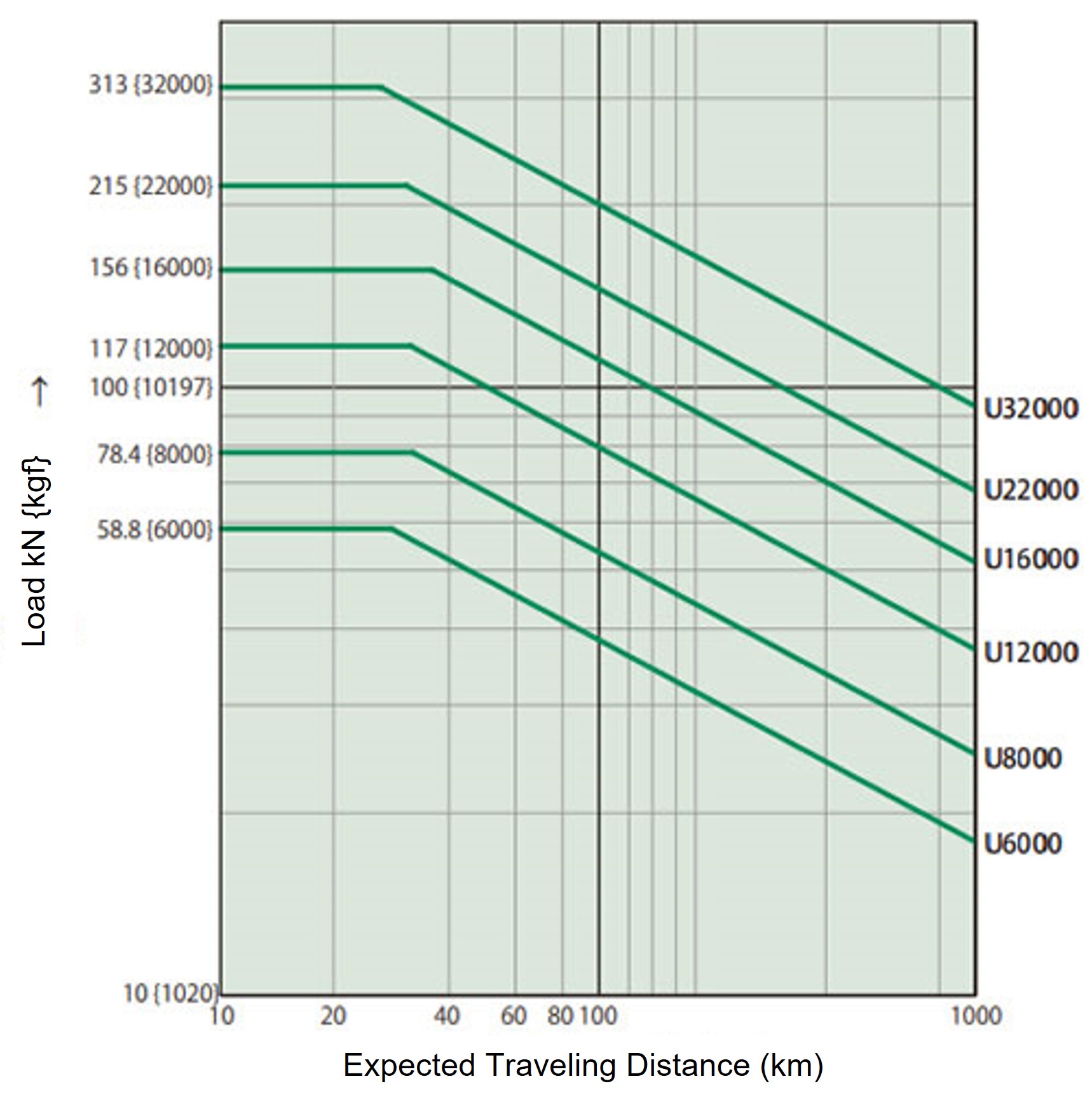

- 7. Calculate the lifespan from the load - expected travel distance, and compare it with the annual travel distance to check the lifespan.

Service factor

| Load Nature | Examples of machines used | Service factor |

|---|---|---|

| Smooth operation without shocks small inertia |

Damper and valve opening and closing Conveyor switching device |

1.0~1.3 |

| Operation with light shock During inertia |

Hopper gate opening and closing, various transfer devices, Various lifter lifting |

1.3~1.5 |

| Operation with large shocks and vibrations Large inertia |

For transporting heavy objects using carts and belt conveyors Buffer, large lid reversing opening and closing device |

1.5~3.0 |

Note: The above Service factor are general guidelines and should be determined taking into consideration the conditions of use.

Multiple factor

| Number of linked units (units) | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|

| Multiple factor | 1.0 | 1.0 | 1.0 | 0.8 | 0.67 |

Note: The maximum number of units that can be linked is six.

Expected travel distance

Expected travel distance is L 10 *Calculated from lifespan.

* L10 life is the lifespan that 90% or more of a group of identical Ball screw can achieve without flaking when operated under the same conditions.

Drive source selection: U series multi-specification

Motors with variable speed reducers, DC motors, servo motors, pole change motors, etc. can be used as drive motors. The motor used has a highly efficient Power Cylinder, so it will reverse depending on the load. Be sure to use one with a brake. The brake should be a spring-closed type with a brake torque of 150% or more.

Please select the drive motor using the following formula.

Calculate the required input torque and use a motor that satisfies the calculated torque value.

For Power Cylinder specifications, please refer to Major Specifications page for each product.

T = W×ℓ 2×π×R×η×1000 + To

T: Required input torque N・m{kgf・m}

W: Load (load) N{kgf}

ℓ: Screw lead mm

R: Gear ratio = 2

η: Overall efficiency = 0.855

To: No-load idling torque N・m{kgf・m}

Note: If a motor with a larger capacity than necessary is used, and it locks mid-stroke, the rotational energy of the motor may apply an impact load to Power Cylinder, which may result in damage. Also, please be aware that Brake external connection.

Selection considerations: U series multi-specification

Push (pull) allowable number of stops

When pushing (pulling) and stopping frequently

If you use it more than 10 times a day, please refer to the standard total number of stops by model in the table below.

| type | LPUC6000 ~ LPUC32000 | ||

|---|---|---|---|

| speed (mm/s) | |||

| LPUC6000 | ~22 | ~30 | |

| LPUC8000 | ~24 | ~36 | |

| LPUC12000 | ~12 | ~22 | |

| LPUC16000 | ~17.5 | ~24 | |

| LPUC22000 | ~17.5 | ~24 | |

| LPUC32000 | ~12 | ~18 | |

| Standard total number of stops (×10 4 times) | 10 | 3 | |

- Note)

1. If you are using the product for a push (pull) stop, we recommend that you use a separate wiring for the brake section. - 2. If you are using the product beyond the limits in the table above, we recommend stopping it with the stroke adjustment LS. However, if you need a push (pull) stop or internal stop due to equipment specifications, please contact us.

- 3. When using with a push (pull) stop, the strength of the mating device should be 250% or more of the rated thrust.

When interlocking operation and stroke position control are performed

When the rod must not move even if an overload is applied from the load side while the motor is stopped

In the case of Type C, a spring mechanism is built into the operating part, so when a large load is applied from the load side, the spring will bend and the rod will move by that amount.

Once the load is removed, it will return to its original position.

- - The multi-specification A type does not have an overload protection function. If you need an overload protection function for the cylinder body, please choose the C type.

- - When attaching a sprocket, gear, pulley, etc. to the input or output shaft, make sure that the overhang load acting on the shaft is below the allowable overhang load.

Allowable OHL ≧ T×f×Lf R

OHL: Overhang load (N{kgf})

T: Load torque (N・m{kgf・m})

f: Transmission element coefficient

Lf: Coefficient depending on the load operating position

R: Pitch circle radius of sprockets, gears, V-pulleys, etc. (m)

QH: Shaft length

ℓ: Load application position

Transmission factor (f)

| Sprocket | 1.00 |

|---|---|

| gear | 1.25 |

| V-belt | 1.50 |

| Flat belt | 2.50 |

Load acting position coefficient (Lf)

| ℓ/QH | 0.25 | 0.38 | 0.5 | 0.75 | 1 |

|---|---|---|---|---|---|

| Lf | 0.8 | 0.9 | 1 | 1.5 | 2 |

Figure 1

| Power Cylinder model number | LPU6000 | LPU8000 | LPU12000 | LPU16000 | LPU22000 | LPU32000 |

|---|---|---|---|---|---|---|

| Allowable overhang load N{kgf} | 5093{520} | 6414{655} | 6050{618} | 7397{755} | 11579{1182} | 13605{1389} |