technical data High-speed lifter Zip Master handling

Operation and inspection procedures

This section describes general handling of Zip Master.

For details, please refer to Instruction Manuals included with the product.

driving

- - Always observe allowable load, allowable overhang load, and allowable lifting speed when using Zip Master. Exceeding these limits may result in damage to the main body or the transported item falling.

- ・Never use the lifter outside of the stroke range, including coasting, under any circumstances. Deviation from the stroke range may result in damage to the equipment. Do not subject the lifter to any impact under any circumstances.

- - Do not allow dust, chips, or other foreign matter to adhere to or get mixed into Zip Chain, moving parts, or detectors. These accelerate wear and tear, leading to serious accidents such as chain breakage and damage to moving parts. Be sure to take measures to prevent foreign matter from entering the lifter body. In addition, install a safety fence around the lifter to prevent people from entering the space below the top frame.

- - Design the sequence circuit so that the motor's holding brake is always activated to prevent the load from dropping when the motor is stopped.

- ・Do not stop the product by hitting it against something under any circumstances. Doing so may cause serious damage to the inside of the product.

- ・The device has some hot spots. Be careful not to touch them with your hands or body, as you may get burned.

- If any abnormality occurs, immediately stop operation to avoid risk of electric shock, injury, or fire.

Inspection Procedure

1. Remove the cover

Cover R must be removed when changing the position of the upper/lower limit sensor or greasing Zip Chain, and cover L must be removed when greasing the guide.

When removing the cover, remove the mounting screws (M6 x 12 cross recessed pan head screws) before removing the cover.

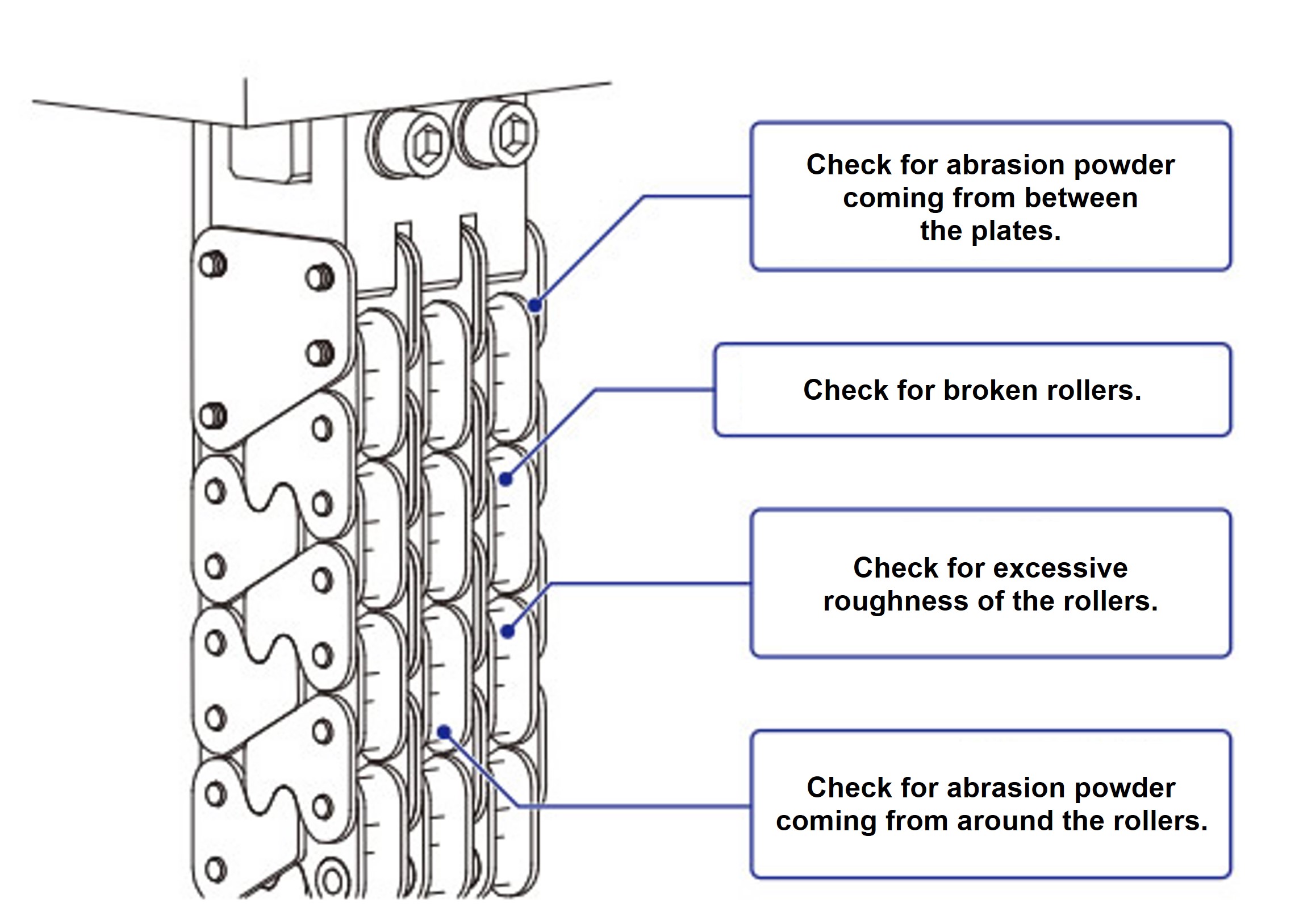

2. Zip Chain Inspection (Every Month)

- (1) Remove the transported item.

- (2) Take measures to prevent the lifting part from falling.

- (3) Check the following points along the entire length of Zip Chain.

- -Check for any oxidized wear debris (reddish brown) coming out from between the plates.

- -is there any oxidized wear debris (reddish brown) on the outer circumference of the chain roller?

in the above cases, grease immediately. - - Check if the chain roller is cracked.

- ・Check the chain rollers for any significant roughness due to wear.

If any of the above occurs, please stop using the product and contact us.

3. Greasing

For details on greasing this product, please refer to the table below.

| Usage category | Greasing amount | Recommended oils and fats | Grease Cycle | |

|---|---|---|---|---|

| Zip Chain | 10 to 15 g per 100 mm of stroke | Heavy-duty grease type 1, No. 2 equivalent Shell Gaddus S2 V220 J 2 (EP) * [Shell Lubricants Japan K.K.] |

3 months or Every 100,000 round trips |

|

| Linear guide | ZMEL0200U ZMEL0500H |

4.5-6.5g (approximately 4.6cc) per block | ||

| ZMEL1000M | 9.0-13.5g (approx. 9.8cc) per block | |||

*Former name: Shell Albania EP Grease 2

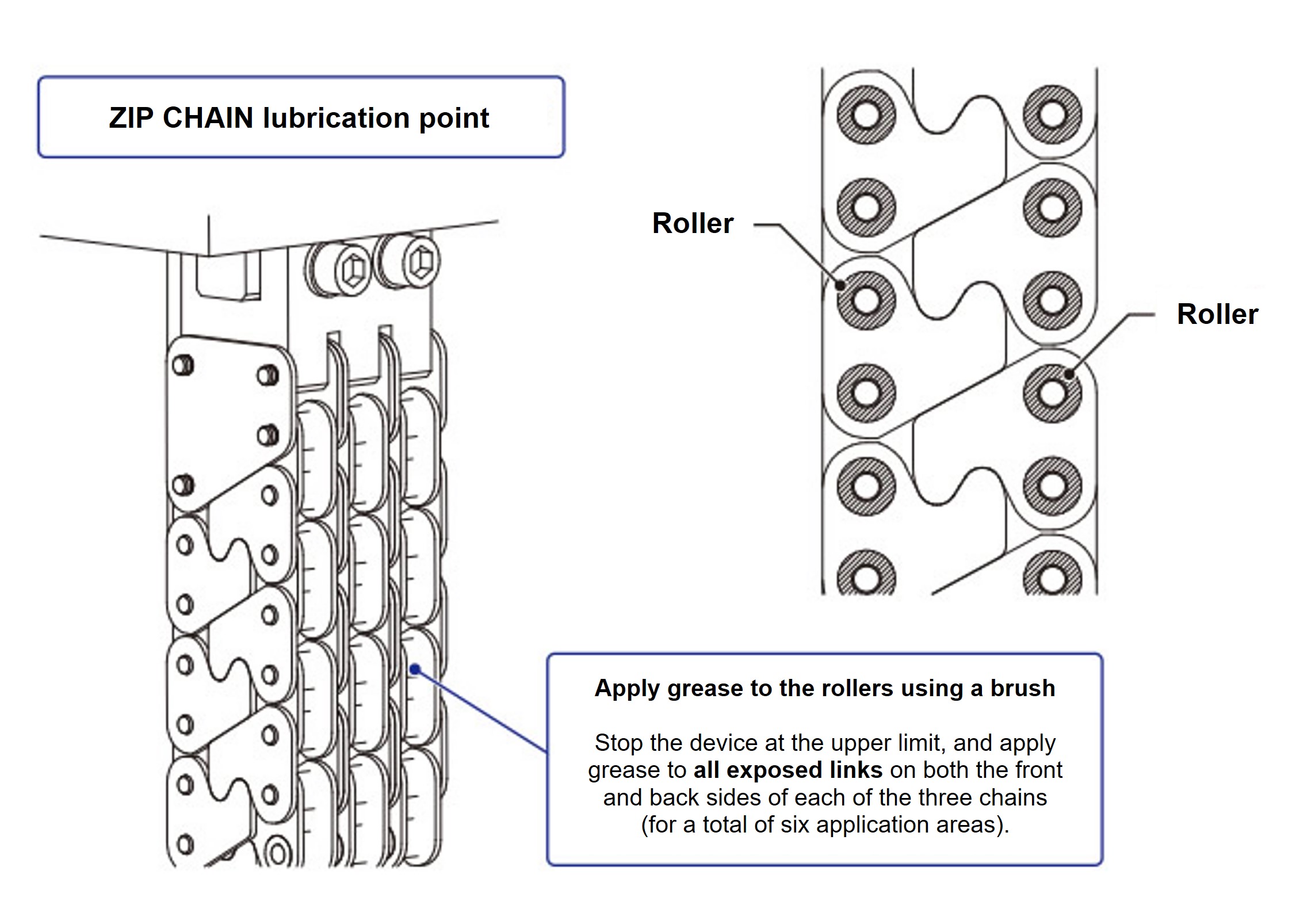

(Zip Chain Greasing)

Follow the steps below to lubricate Zip Chain.

- [1] Remove all items from the top frame.

- [2] Take measures to prevent the lifting unit from falling.

- [3] As shown in the diagram on the right, grease all exposed rollers.

(Greasing the guide part)

Supply the specified amount of grease through the grease nipple.

After greasing, perform a break-in run and remove any excess grease before starting operation.