technical data Electrical controller Shock Monitor

Torque monitoring

For the basic type, if you set parameter 19 [POWER/TORQUE] to TORQUE, you can monitor the calculated torque value.

Torque monitoring compares the preset overload level (set as a percentage of torque) with the calculated torque value (%).

This is a very useful function when the frequency needs to be changed arbitrarily during inverter operation.

1. Torque calculation formula

When monitoring torque with Shock Monitor, the torque value is calculated using the following formula from three elements: "detected power (%)," "motor supply voltage frequency," and "estimated motor copper loss (%)."

(Torque at 60Hz is 100%)

Torque calculation value (%) = (detected power - estimated motor copper loss) x 60 frequency

2. Differences between power monitoring and torque monitoring in inverter operation

When variable speed operation is performed using an inverter, if the frequency is halved, the amount of work will be roughly halved even if the load torque is constant, and the motor's power consumption will also be roughly halved.

In the case of power monitoring, if the frequency is halved, the overload detection level must also be halved using the multi-stage switching function in order to accurately detect overloads.

On the other hand, with torque monitoring, it is possible to eliminate the need to change the overload detection level by dividing the halved detected power by the frequency of the motor supply voltage read by Shock Monitor is a very convenient function when operating at a stepless, arbitrary frequency.

3. Caution when monitoring torque

- - Torque calculation value is based on the rated torque at 60Hz.

- ・In order to reduce errors in the torque calculation value, a correction calculation is performed in which the estimated motor copper loss is subtracted. However, when used at low frequencies (approximately 20 Hz or less), the detected power in the above formula becomes small and the frequency in the denominator becomes small, so care must be taken as the error becomes very large.

4. Torque calculation value at each frequency

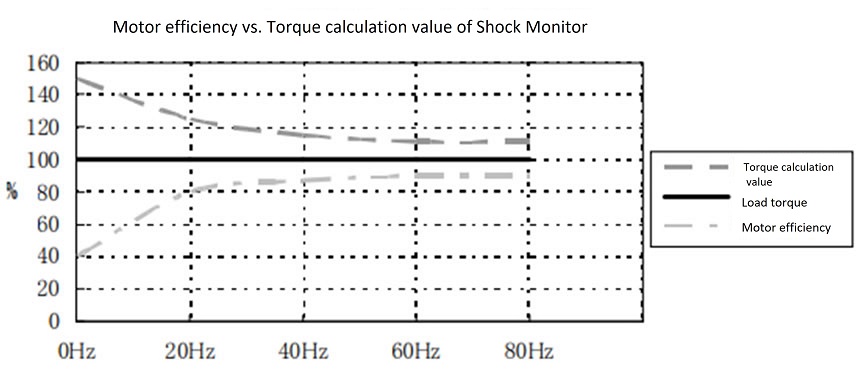

Motor efficiency becomes extremely poor at low frequencies, resulting in a large error in Shock Monitor 's torque calculation values, as shown in the diagram below.

As shown in the figure, when torque monitoring is performed at a low frequency, the calculated torque value becomes larger and the output relay becomes more likely to operate.

When using a frequency of 20Hz or less for positioning operation, etc., we recommend fixing the low speed frequency and using multi-stage settings in combination.