technical data Coupling Selection and Procedure

If you would like to see the selection procedures and important points, please proceed below.

If you would like to narrow down or tentatively select a product series,

Please click here.

If your usage conditions have been decided and you would like a detailed selection,

Please click here.

Power Rigid Coupling EPR Series Selection

Taper lock tightening torque and transmission torque

| Model number | EPR50 | EPR58 | EPR68 | EPR78 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Pressure bolt | M6 | M6 | M6 | M6 | |||||

| Tightening torque N・m{kgf・m} |

16.7{1.7} | 16.7{1.7} | 16.7{1.7} | 16.7{1.7} | |||||

| Shaft Hole Diameter | 16 | 90{9.2} | - | - | - | ||||

| 17 | 98{10.0} | - | - | - | |||||

| 18 | 106{10.8} | 78 {8.0} | - | - | |||||

| 19 | 115{11.7} | 94{9.6} | - | - | |||||

| 20 | 123{12.5} | 110{11.2} | - | - | |||||

| 22 | 139{14.2} | 141{14.4} | 144{14.7} | - | |||||

| 24 | - | 172{17.6} | 191{19.5} | - | |||||

| 25 | - | 188{19.2} | 216{22.0} | - | |||||

| 28 | - | - | 287{29.3} | - | |||||

| 30 | - | - | 334{34.1} | 176{18.0} | |||||

| 32 | - | - | 382{39.0} | 212{21.6} | |||||

| 35 | - | - | 454{46.3} | 264{26.9} | |||||

| 36 | - | - | - | 281{28.7} | |||||

| 38 | - | - | - | 316{32.2} | |||||

| 40 | - | - | - | 351{35.8} | |||||

| 42 | - | - | - | 385{39.3} | |||||

| 45 | - | - | - | 437{44.6} | |||||

| 48 | - | - | - | 489{49.9} | |||||

*The bolded numbers indicate stock shaft hole diameters. For shaft hole diameter combinations, please refer here.

Selection

Torque Capacity

Calculate the maximum torque (Tmax) by multiplying the maximum torque (T'max) of the servo motor you will be using by the load Service factor for starting and stopping.

Check the transmission torque of the taper lock.

- Tmax = T'max × Service factor (SF)

- Tmax: Maximum torque applied to the coupling N・m{kgf・m}

- T'max: Maximum torque of servo motor N・m{kgf・m}

| Load Type | Uniform Load | Moderately fluctuating load | Extremely fluctuating load |

|---|---|---|---|

| Service factor (SF) | 1.2 | 1.4 | 1.5 |

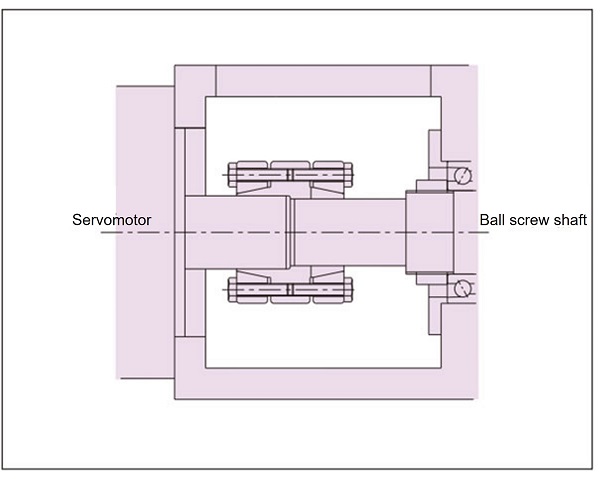

Installation example