technical data Reducer TERVO Servo Motor Reducer Technical Data

Hollow shaft type keyless specification

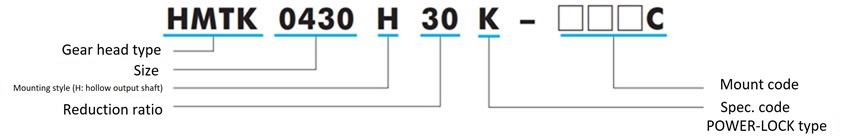

Hypoid gear head HMTK type

The dedicated hollow shaft with Power-Lock allows keyless fastening, further enhancing the functionality of the hollow shaft.

It makes installation and removal easier, reduces the number of parts in machinery and equipment, and saves space.

Features

- - No need to process keyways on the driven shaft, reducing the number of parts and installation work.

- -Since there is no key, phase alignment is not required, making it easier to install and remove the reducer.

- - Because it is a strong frictional fastening, there is no need for measures to prevent it from coming loose or coming loose, and there is no backlash with the driven shaft.

- -Special shaft end covers are also available (Hypoid Motor: 0.2 to 0.4kW, 0.75kW-1/5 to 1/50 only).

Hypoid gearhead specifications

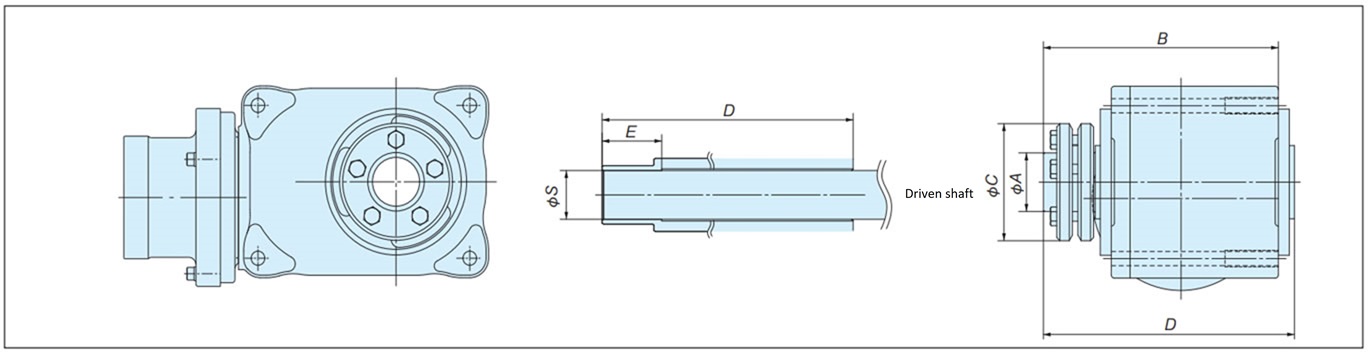

| size | Reduction ratio | ΦS | ΦA | ΦC | E | D | B | Power-Lock Model Number | Bolt size | Tightening torque MA N・m {kgf・m} |

|---|---|---|---|---|---|---|---|---|---|---|

| HMTK02 | 1/5 ~ 1/60 | 20 | 30 | 60 | 31 | 122.5 | 118 | PL030X060SL | M5×18 | 4.9 {0.15} |

| 1/80 ~ 1/200 | 30 | 36 | 72 | 38 | 160 | 150 | PL036X072SL | M6×20 | 11.8 {1.2} | |

| HMTK04 | 1/5 ~ 1/50 | |||||||||

| 1/60 ~ 1/200 | 35 | 44 | 80 | 44 | 188 | 178 | PL044X080SL | M6×20 | 11.8 {1.2} | |

| HMTK075 | 1/5 ~ 1/50 | |||||||||

| 1/60 ~ 1/200 | 45 | 55 | 100 | 45 | 210 | 200 | PL055X100SL | M6×25 | 11.8 {1.2} | |

| HMTK15 | 1/5 ~ 1/80 |

- Note) The dimensional tolerance of the driven shaft to be fastened to Hypoid Motor hollow shaft should be ΦS h6, the finished length should be dimension E or more, and the surface roughness should be 12S or less. Set the finished surface of the driven shaft so that it is at the E dimension position.

- Note) Dedicated shaft end covers are also available for 0.2 to 0.4 kW and 0.75 kW 1/5 to 1/50.