technical data Drive chain Roller Chain Selection

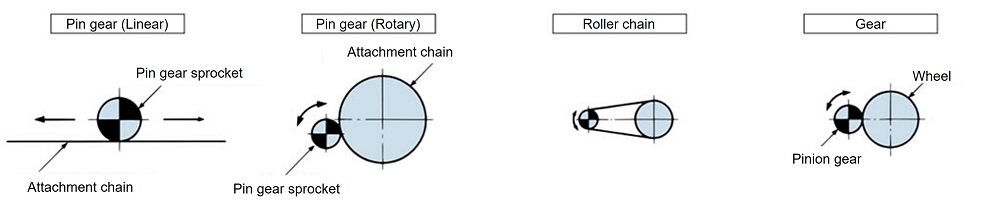

9. Introduction to chain-type pin gears

To achieve linear motion or large-diameter rotational motion, roller chains and gears are generally used, connected to a drive source (such as a motor) via a reducer.

However, roller chain systems face problems such as space requirements, while gear systems require precision machining and are expensive.

In such cases, the pin gear method is ideal.

Pin gear drive uses a roller chain wrapped around the outer periphery of a drum to form a wheel, and a chain-type pin gear sprocket with a special tooth profile is used instead of a pinion gear.

For linear motion, a roller chain is installed in a straight line instead of a rack.

| item | Pin gear system | Roller chain system | Gear system |

|---|---|---|---|

| Restrictions on shaft distance | Provided | none | Provided |

| Number of meshing teeth | few | many | few |

| Speed ratio range | Unlimited | Up to 1:7 | Unlimited |

| Tooth profile | Special tooth profile | Sprocket tooth profile | Involute |

| Meshing precision | Normal | Normal | precision |

9.1 Features of pin gears

- 1. Large speed ratio (1:5 or more) is economical, especially when the drum diameter is large.

- 2. Installation and maintenance are easy; simply bolt the roller chain attachment to a drum, etc.

- 3. Greater freedom in designing the drum outer diameter, straight length, etc.

- 4. It is not suitable for extremely precise driving and generates more noise than gears. However, it does not require high precision for installation and does not require precision machining like gears.

- 5. Grease lubrication is available.

9.2 Chain installation method and precautions

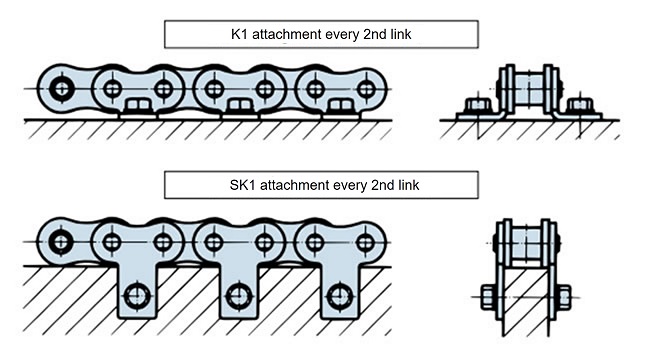

1. When used in a straight line (rack) with the roller facing upward

Uses RS roller chain

Use connecting links on both ends, attach metal fittings, and tighten the chain with bolts and nuts until there is no slack. Use double nuts or other locking devices on both ends to prevent loosening.

When installing, do not support the chain rollers on the rail, as the teeth of the pin gear sprocket may interfere with the rail.

We do not recommend using RS roller chain as it is prone to tooth skipping and tooth interference.

Uses RS Attachment Chains

Attach K1 and SK1 outer link attachments every two links, tension the chain straight to prevent slack or meandering, and tighten bolts and nuts every two to four links. K attachments are recommended.

Mounting holes are machined to fit the actual part.

Note: When using the SK1 attachment, do not support the chain rollers. The teeth of the pin gear sprocket may interfere with the rail.

Use bolts with a strength classification of 8.8 or higher (JIS B 1051:2014 nominal tensile strength of 800 MPa or higher).

(e.g. SCM435 heat treated bolts)

Note) The chain length is designed to be longer than travel distance, taking into account possible overrun depending on the conditions of use.

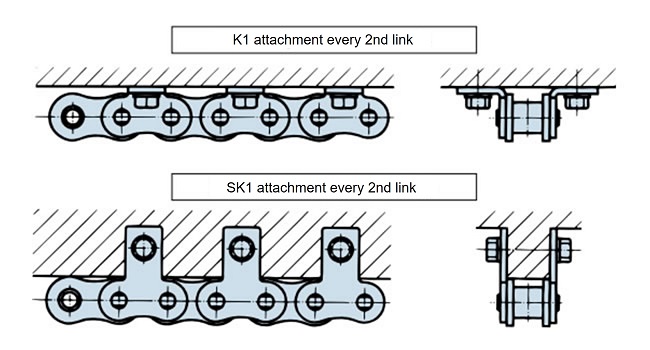

2. When used in a straight line (rack) with the roller facing downwards

Attach K1 and SK1 outer link every two links, stretch the chain straight to prevent slack or meandering, and tighten with bolts and nuts every two links. When installing, do not support the chain rollers.

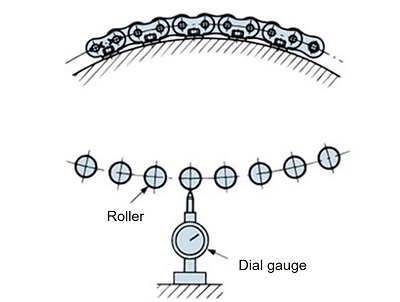

3. Full and partial winding around the drum

- - The length of roller chain with attachments is manufactured within a range of -0.05 to 0.15% of the reference length (nominal pitch x number of links). Therefore, the chain may sag when wound around the drum. Adjust the slack by inserting a shim between the drum and the chain attachment.

- ・The K attachment can be adjusted with a shim, making it easier to attach to the outer periphery of the drum than the SK attachment.

- - If the drum is not perfectly round, adjust the shim thickness to make it perfectly round when winding the chain around it.

Adjustments are made using measuring tools such as dial gauges and Tuscan gauges as shown in the figure on the right. - - The tapped holes on the drum side are machined by matching them to the actual chain attachment holes.

4. Full and partial winding around the drum inner circumference

- - The sprocket tooth profile is special. Please contact us.

5. When used for horizontal winding (horizontal drive)

- Please refer to section 3.

- If it is inscribed, please contact us.

6. Installing the sprocket

- - Please use a sprocket for chain-type pin gears.

- - Adjust the sprocket mounting shaft so that there is no strong contact with the side of the sprocket teeth.

RS Curved chain are curved sideways, so they come into contact with the side of the sprocket teeth. - ・The play α between the roller and the sprocket tooth root must be equal to or less than the dimensions in the table on the right.

However, make sure that the rollers do not come into contact with tooth root. - ・If there is a possibility that the above play may not be secured during operation due to driving or environmental conditions,

A tooth profile with a larger α will be required. Please contact us.

| Chain size | α |

|---|---|

| RS80 or less | 1.0mm |

| RS100~RS180 | 1.5mm |

| RS200以上 | 2.0mm |