Ultra-high molecular weight polyethylene

The plastic Top chain is born!

High impact resistance even at low temperatures

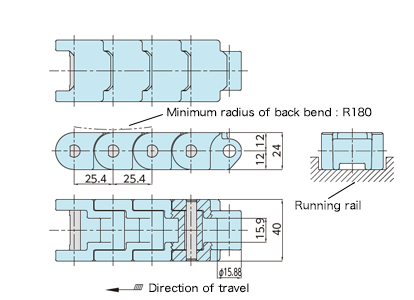

Plastic block chain RSP80 Link Material

First use of UHMWPE (ultra-high molecular weight polyethylene)!

Taking advantage of the material's properties, we have added it to our lineup of Plastic block chain as "low-temperature and chemical-resistant UPE."

It has high impact resistance, excellent chemical resistance, and complies with the Food Sanitation Act.In addition, it is made of materials approved by the FDA (U.S. Food and Drug Administration), so it can be used in a variety of situations.

If you are considering other plastic Top chain, please contact us.

Features of low-temperature and chemical-resistant UPE

High impact resistance even at low temperatures

Excellent chemical resistance

Excellent wear resistance

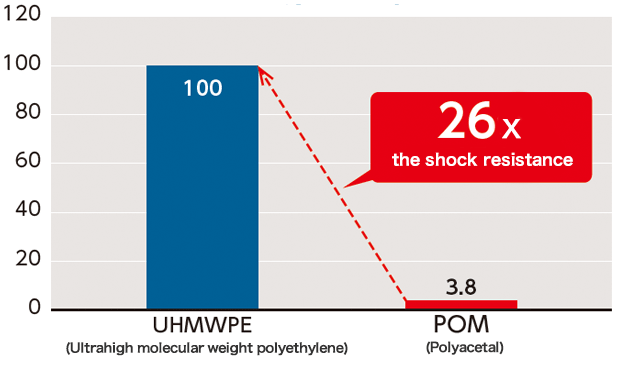

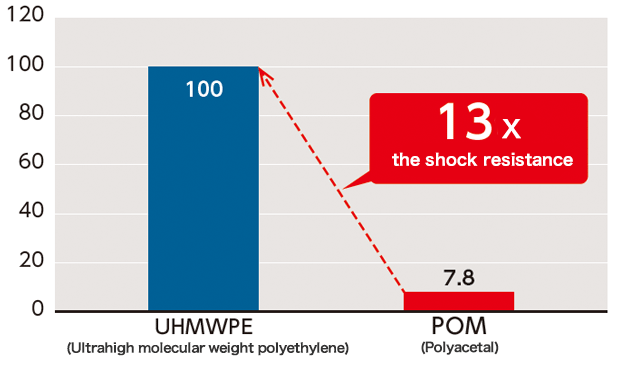

High impact resistance even at low temperatures

UHMWPME (ultra-high molecular weight polyethylene) is shock-resistant and does not easily shatter when broken, reducing the risk of foreign matter getting into the chain due to breakage.In addition, the material used is FDA (U.S. Food Sanitation Administration) certified and complies with the Food Sanitation Act, so it can be used safely to transport food.

When used in a low temperature atmosphere

When used in a room temperature atmosphere

- Test conditions: Charpy impact test, test method JIS K 7111-1, test temperature: room temperature 23°C/low temperature -60°C

- The graph above shows the results of our internal tests.

- This is a comparison with the impact strength of UHMWPE (ultra-high molecular weight polyethylene) set at 100.

Comparison of cracking patterns when used in low temperature environments by material

UHMWPE (ultra-high molecular weight polyethylene)

POM (polyacetal)

- [Test conditions] Test method: Precision universal testing machine Autograph, Test temperature: -70℃

Excellent chemical resistance

Chemical resistance to various liquids

| liquid name | POM *1 (Polyacetal) |

SUS304 (Stainless steel pin) |

UHMWPE (ultra-high molecular weight polyethylene) |

|---|---|---|---|

| hydrogen peroxide (3%) |

× | ○ | ○ |

| Formic acid (50%) |

× | ○ | ○ |

| Citric acid | × | ○ | ○ |

| Chromic Acid (5%) |

× | ○ | ○ |

| acetic acid (10%) |

× | ○ | ○ |

○: Sufficient corrosion resistance ×: No corrosion resistance

- 1. Polyacetal applicable specifications: Standard Series / Low friction specification WR / Low friction and wear-resistant specification LFW, LFG, LFB / Low friction and wear-resistant specification HG / Advanced low friction/wear resistant series ALF / Antibacterial and antifungal specification MWS / Conductive specification E

- 2. The above table shows laboratory results at 20°C and does not represent a guaranteed level. When actually using the product, please consider the temperature, operating conditions, etc.

Reagents without a concentration indication are saturated or 100% solutions. Please note that the conditions will change if you mix solutions.

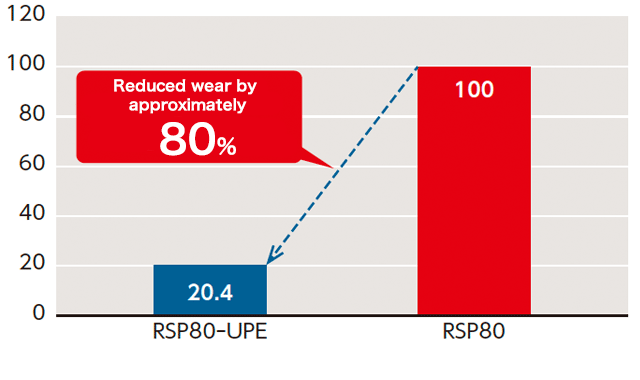

Excellent wear resistance

Comparison of wear volume between low temperature and chemical resistant UPE and Standard Series

- This is a comparison with Standard Series wear amount set at 100 (when used in a room temperature environment).

- Test conditions: Chain speed: 60 m/min Load: 6 kg weight Rail material: SUS304 Environment: 23°C, no lubrication

- The graph above shows the results of our internal tests.

Recommended industries/applications for low temperature and chemical resistant UPE

logistics

- Unmanned transportation within frozen food stock warehouses, etc.

Bakery and Food

- Transporting frozen foods on freezer conveyors

- Food conveyors that are cleaned with chemicals to prevent contamination

battery

- Conveyors that require chemical resistance, such as secondary batteries

- Conveyors for cleaning lines for printed circuit boards, silicon wafers, etc.

Low temperature and chemical resistant UPE product lineup