Cable Carrier (CABLEVEYOR) Plastic Series Special Specifications

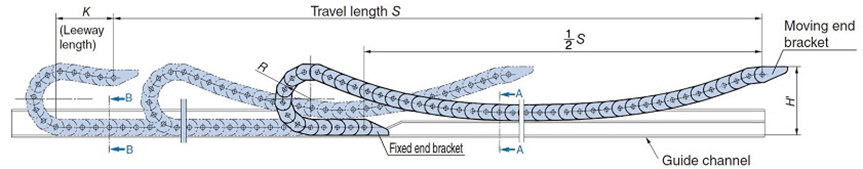

Gliding arrangement

Gliding arrangement specifications list Open type

| size | pitch P mm |

Inner Height H mm |

bending radius R mm |

room length K mm |

Maximum travel length Smax m |

maximum support mass kg/m |

maximum move speed m/min |

Installation height H' mm |

sliding shoe installation

|

Main unit sliding shoe Allowable wear amount () is sliding shoe mm |

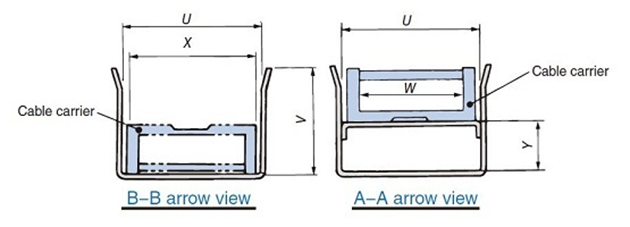

Moving end fitting | Inner width W mm |

X mm |

|

V mm |

Y mm |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | specification classification |

|||||||||||||||||||

| TKP35H22 Note 3) |

35 | 22 | 37 | 100 | 20 20 to 40 Note) 1 40~ Note) 2 |

1.0 | 40 | 150 | - | 1.0 | Engineering plastics | standard | 25 38 50 |

W+12 | W+18 | 60 | 30 | |||

| 50 | 150 | |||||||||||||||||||

| 75 | 150 | special shape | ||||||||||||||||||

| 63 | 77 | 83 | ||||||||||||||||||

| 100 | 250 | |||||||||||||||||||

| TKP45H25 Note 3) |

45 | 25 | 50 | 140 | 30 30 to 60 Note) 1 60~ Note) 2 |

2.0 | 120 | 190 | - | 1.5 | steel | special shape | 38 | 56 | 62 | 70 | 36 | |||

| 75 | 140 | 230 | ||||||||||||||||||

| 95 | 140 | 230 | 58 78 103 |

W+20 | W+26 | 70 | 36 | |||||||||||||

| 125 | 250 | 230 | ||||||||||||||||||

| 150 | 400 | 230 | ||||||||||||||||||

| 200 | 700 | 230 | ||||||||||||||||||

| TKP58H39 Note 3) |

58 | 39 | 60 | 190 | 45 45 to 75 Note) 1 75~ Note) 2 |

3.0 | 150 | 200 | - | 1.5 (5.0) |

steel | special shape | 50 75 100 125 |

W+21 slide With shoe W+25 |

W+27 slide With shoe W+31 |

100 | 52 slide With shoe 59 |

|||

| 75 | 190 | 200 | △ | |||||||||||||||||

| 90 | 190 | 250 | △ | |||||||||||||||||

| 125 | 220 | 250 | △ | |||||||||||||||||

| 150 | 400 | 250 | △ | |||||||||||||||||

| 200 | 600 | 250 | △ | |||||||||||||||||

| TKP62H34 | 62.5 | 34 | 75 | 190 | 50 50 to 80 Note) 1 80~ Note) 2 |

3.0 | 120 | 200 | - | 1.0 | steel | standard | 150 200 |

W+22 | W+28 | 108 | 54 | |||

| 90 | 190 | 250 | ||||||||||||||||||

| 125 | 220 | 250 | special shape | |||||||||||||||||

| 150 | 400 | 250 | ||||||||||||||||||

| 200 | 700 | 250 | ||||||||||||||||||

| TKP68H46 Note 3) |

68 | 46 | 75 | 190 | 45 45 to 75 Note) 1 75~ Note) 2 |

3.0 | 150 | 200 | △ | 1.5 (5.0) |

Engineering plastics or steel |

special shape | 75 100 125 150 175 |

W+22 slide With shoe W+26 |

W+32 | 126 | 63 slide With shoe 70 |

|||

| 100 | 190 | 200 | △ | |||||||||||||||||

| 125 | 220 | 250 | △ | |||||||||||||||||

| 150 | 400 | 250 | △ | |||||||||||||||||

| 200 | 600 | 250 | △ | |||||||||||||||||

| 250 | 750 | 300 | △ | |||||||||||||||||

| TKP90H50 | 90 | 50 | 130 | 270 | 80 80 to 120 Note) 1 120~ Note) 2 |

4.0 | 150 | 300 | - | 1.5 | steel | special shape | 100 150 200 |

W+30 | W+36 | 156 | 78 | |||

| 200 | 350 | 350 | ||||||||||||||||||

| 250 | 600 | 350 | ||||||||||||||||||

| TKP91H56 Note 7) |

91 | 56 | 200 | 300 | 80 80 to 120 Note) 1 120~ Note) 2 |

6.0 | 200 | 380 | ● | (7.0) | Engineering Plastics Steel bushing |

special shape Note) 5 |

150 to 500 (every 50mm) Note) 8 |

W+42 | W+50 | 188 | 94 | |||

| 250 | 600 | 380 | ||||||||||||||||||

| 300 | 750 | 380 | ||||||||||||||||||

| TKP91H80 Note 7) |

91 | 80 | 200 | 380 | 100 100 to 120 Note) 1 120~ Note) 2 |

8.0 | 200 | 400 | ● | (7.0) | Engineering Plastics Steel bushing |

special shape Note) 5 |

150 to 500 (every 50mm) Note) 8 |

W+56 | W+64 | 236 | 118 | |||

| 250 | 500 | 400 | ||||||||||||||||||

| 300 | 750 | 400 | ||||||||||||||||||

| 350 | 1000 | 400 | ||||||||||||||||||

| 400 | 1200 | 400 | ||||||||||||||||||

| TKP125H74 | 125 | 74 | 185 | 380 | 90 90~120 Note)1 120~ Note) 2 |

6.0 | 150 | 400 | - | 1.5 | steel | special shape | 150 250 350 |

W+40 | W+46 | 212 | 106 | |||

| 250 | 600 | 400 | ||||||||||||||||||

| 350 | 1000 | 400 | ||||||||||||||||||

| TKMK47H28 | 47.5 | 28 | 100 | 150 | twenty five 25 to 50 Note) 1 50~ Note) 2 |

2.0 | 60 | 200 | ● | (1.5) | steel | special shape Note) 5 |

56 104 152 192 |

W+17 | W+22 | 84 | 42 | |||

| 160 | 250 | 250 | ||||||||||||||||||

| 200 | 450 | 250 | ||||||||||||||||||

| TKMK65H42 | 65 | 42 | 95 | 200 | 70 70 to 90 Note) 1 90~ Note) 2 |

4.0 | 200 | 250 | ● | (1.5) | steel | special shape Note) 6 |

66 106 154 194 258 |

W+34 | W+39 | 120 | 60 | |||

| 115 | 200 | 250 | special shape Note) 5 |

|||||||||||||||||

| 145 | 200 | 300 | ||||||||||||||||||

| 220 | 500 | 300 | ||||||||||||||||||

| TKMK95H58 | 95 | 58 | 140 | 290 | 80 80-90 Note) 1 90~ Note) 2 |

6.0 | 200 | 300 | ● | (1.5) | steel | special shape Note) 5 |

114 162 210 258 306 402 512 |

W+34 | W+39 | 167 | 83.5 | |||

| 170 | 290 | 300 | ||||||||||||||||||

| 200 | 300 | 380 | ||||||||||||||||||

| 290 | 600 | 380 | ||||||||||||||||||

| TKMK125H72 | 125 | 72 | 180 | 380 | 100 100 to 120 Note) 1 120~ Note) 2 |

6.0 | 200 | 400 | ● | (1.5) | steel | special shape Note) 5 |

151 247 359 407 455 503 |

W+45 | W+50 | 199 | 99.5 | |||

| 220 | 380 | 400 | ||||||||||||||||||

| 260 | 500 | 400 | ||||||||||||||||||

| 340 | 900 | 400 | ||||||||||||||||||

| 380 | 1100 | 400 | ||||||||||||||||||

Gliding arrangement specifications list: Closed type

| size | pitch P mm |

Inner Height H mm |

bending radius R mm |

room length K mm |

Maximum travel length Smax m |

maximum support mass kg/m |

maximum move speed m/min |

Installation height H' mm |

sliding shoe installation

|

Main unit sliding shoe Allowable wear amount () is sliding shoe mm |

Moving end fitting | Inner width W mm |

X mm |

|

V mm |

Y mm |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | specification classification |

|||||||||||||||||||

| TKC34H25 | 34 | 25 | 70 | 110 | 50 50 to 70 Note) 1 70~ Note) 2 |

2.0 | 150 | 200 | - | 1.0 | steel | standard | 50 90 130 |

W+20 | W+30 | 80 | 40 | |||

| 100 | 110 | 200 | special shape | |||||||||||||||||

| 150 | 200 | 250 | ||||||||||||||||||

| TKC47H36 | 47 | 36 | 100 | 150 | 70 70-80 Note) 1 80~ Note) 2 |

3.0 | 200 | 250 | - | 1.0 | steel | standard | 80 160 |

W+26 | W+36 | 110 | 55 | |||

| 150 | 150 | 300 | special shape | |||||||||||||||||

| 200 | 400 | 300 | ||||||||||||||||||

| 250 | 600 | 300 | ||||||||||||||||||

| TKC64H50 | 64 | 50 | 135 | 200 | 80 80 to 120 Note) 1 120~ Note) 2 |

4.0 | 200 | 300 | - | 1.5 | steel | special shape | 110 120 |

W+30 | W+40 | 150 | 75 | |||

| 200 | 300 | 350 | ||||||||||||||||||

| 250 | 500 | 350 | ||||||||||||||||||

| 300 | 750 | 350 | ||||||||||||||||||

| TKC85H68 | 85 | 68 | 180 | 260 | 90 90 to 120 Note) 1 120~ Note) 2 |

6.0 | 200 | 400 | - | 1.5 | steel | special shape | 150 200 300 350 |

W+36 | W+46 | 200 | 100 | |||

| 250 | 500 | 400 | ||||||||||||||||||

| 350 | 1000 | 400 | ||||||||||||||||||

| TKC91H56 Note) 7 |

91 | 56 | 200 | 300 | 80 80 to 120 Note) 1 120~ Note) 2 |

6.0 | 200 | 380 | ● | (7.0) | Engineering Plastics Steel bushing |

special shape Note) 5 |

150 to 400 (every 50mm) |

W+42 | W+50 | 188 | 94 | |||

| 250 | 600 | 380 | ||||||||||||||||||

| 300 | 750 | 380 | ||||||||||||||||||

| TKC91H80 Note) 7 |

91 | 80 | 200 | 380 | 100 100 to 120 Note) 1 120~ Note) 2 |

8.0 | 200 | 400 | ● | (7.0) | Engineering Plastics Steel bushing |

special shape Note) 5 |

150 to 400 (every 50mm) |

W+56 | W+62 | 236 | 118 | |||

| 250 | 500 | 400 | ||||||||||||||||||

| 300 | 750 | 400 | ||||||||||||||||||

| 350 | 1000 | 400 | ||||||||||||||||||

| 400 | 1200 | 400 | ||||||||||||||||||

| TKMT47H26 | 47.5 | 26 | 100 | 150 | twenty five 25 to 50 Note) 1 50~ Note) 2 |

2.0 | 60 | 200 | ● | (1.5) | steel | special shape Note) 5 |

56 80 104 152 192 |

W+17 | W+22 | 84 | 42 | |||

| 160 | 250 | 250 | ||||||||||||||||||

| 200 | 450 | 250 | ||||||||||||||||||

| TKMT65H38 | 65 | 38.5 | 95 | 200 | 70 70 to 90 Note) 1 90~ Note) 2 |

4.0 | 200 | 250 | ● | (1.5) | steel | special shape Note) 6 |

66 106 130 194 258 |

W+34 | W+39 | 120 | 60 | |||

| 115 | 200 | 250 | special shape Note) 5 |

|||||||||||||||||

| 145 | 200 | 300 | ||||||||||||||||||

| 220 | 500 | 300 | ||||||||||||||||||

| TKMT95H54 (Plastic cover type) |

95 | 54.5 | 140 | 290 | 80 80-90 Note) 1 90~ Note) 2 |

6.0 | 200 | 300 | ● | (1.5) | steel | special shape Note) 5 |

114 130 162 258 306 |

W+34 | W+39 | 167 | 83.5 | |||

| 170 | 290 | 300 | ||||||||||||||||||

| 200 | 300 | 380 | ||||||||||||||||||

| 290 | 600 | 380 | ||||||||||||||||||

| TKMT125H68 | 125 | 68.5 | 220 | 380 | 100 100 to 120 Note) 1 120~ Note) 2 |

8.0 | 200 | 400 | ● | (1.5) | steel | special shape Note) 5 |

135 183 247 |

W+45 | W+50 | 199 | 99.5 | |||

| 260 | 500 | 400 | ||||||||||||||||||

| 340 | 900 | 400 | ||||||||||||||||||

| 380 | 1100 | 400 | ||||||||||||||||||

Note

1. Varies depending on the amount of supporting material. Please contact us.

2. It may be possible to use this product depending on the installation conditions. Please contact us for details.

3. The inner arm opening/closing types of TKP35H22, TKP45H25, TKP58H39 and TKP68H46 cannot be used.

4. TKP type MW specification (low friction, low wear specification) is not recommended.

5. Fixed end bracket is also specially designed with a slide.

6. Both the moving end bracket and Fixed end bracket are specially designed with slides.

7. For TKP91 and TKC91, cover the fixed end bracket with guide channel.

8.Inner width: 150/175/200/225/250/275/300/325/350/400/450/500mm

お問合せ先について

ホームページからのお問合せ

英語でのお問い合わせは、つばきグループホームページの問合せページを開きます。

If you are purchasing this product outside of Japan, please contact your nearest overseas office at the link below.